2C multi-purpose anchor SHARK® TWIST One anchor. Eight knots.

2C plastic multi-purpose anchor Shark TWIST

DWL-PLA-SHARK-TWIST-12X66

Register now and access more than 125,000 products

Quick, flexible installation

- Easy: Can be set flush using just one finger without the need for a hammer

- Fast: Very easy insertion of the screw

- Versatile: For wood threads and metric threads

- Flexible: Each anchor size can be combined with several screw diameters

High degree of security

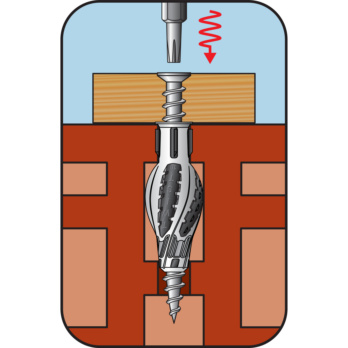

- Innovative: 8-fold knotting with extremely large contact surface

- Tested: Tested, high load values

- Optimised: Low installation torque and high overtorque

- No rotation of the anchor in the drill hole

- Certified: ETA assessment for anchors in a redundant non-structural system in concrete and masonry in conjunction with the ASSY®-D screw

Resistant to rotting, weathering and ageing

- UV resistant < 6 weeks

- Halogen and silicone free

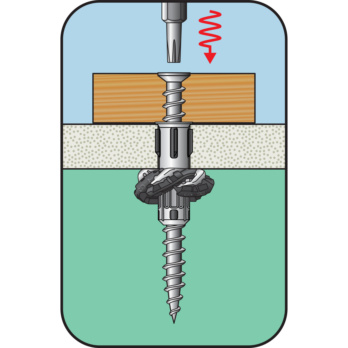

EXTRA: Thanks to the special plastic composition of the SHARK® TWIST, even screws and bolts with metric threads can be screwed in without any problems, for example, threaded fittings or rods for suspended items in plumbing installations or metric screws

ETA-22/0877

Autoclaved aerated (cellular) concrete

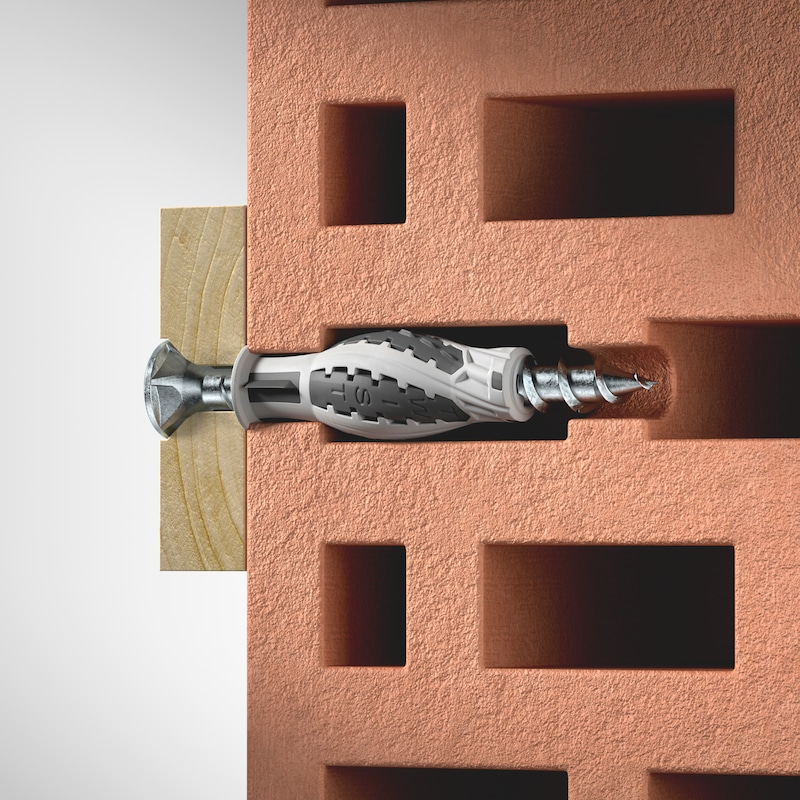

Vertically perforated brick with small bars

Vertically perforated bricks with lateral bars

Concrete

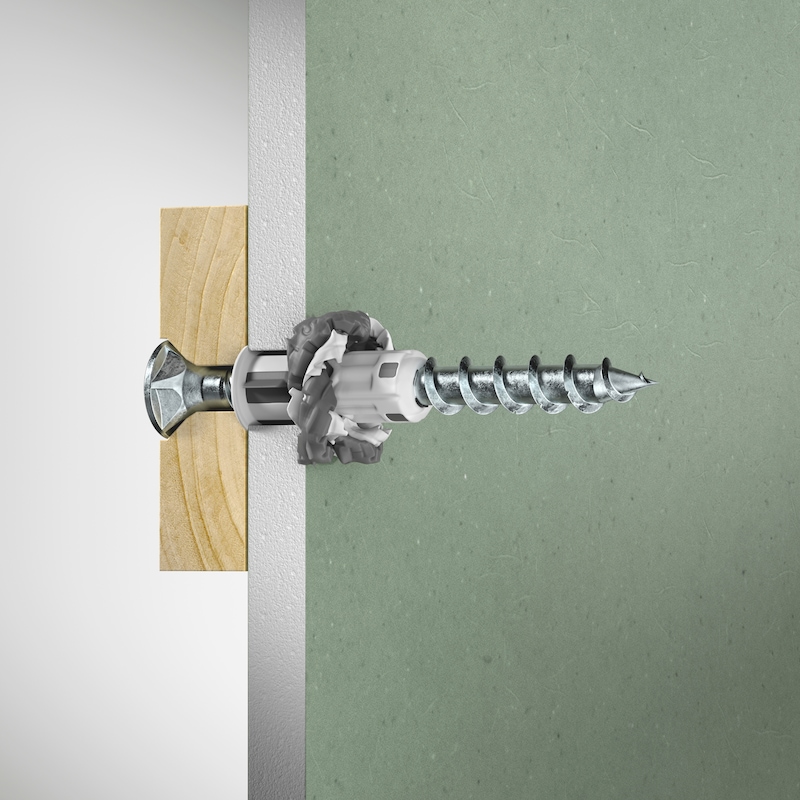

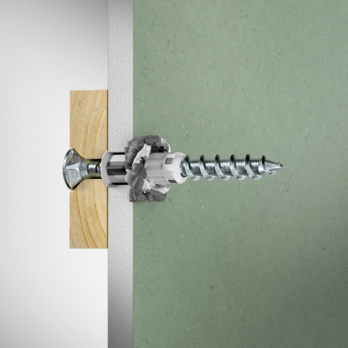

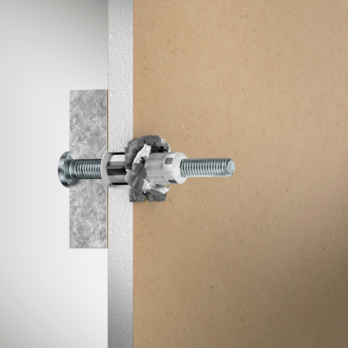

Panel materials with chipboard screw

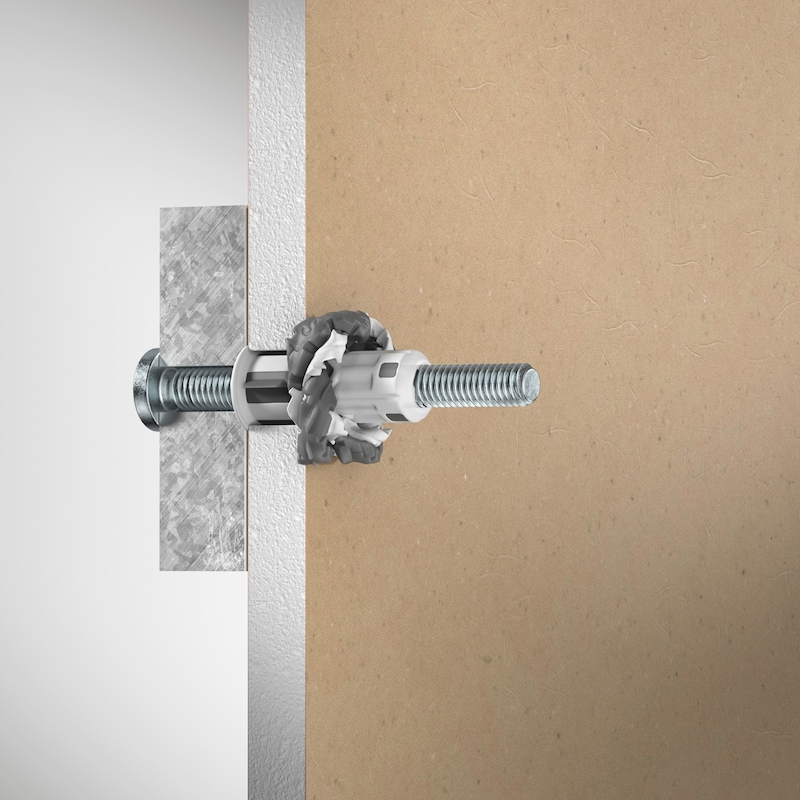

Panel materials with metric screw

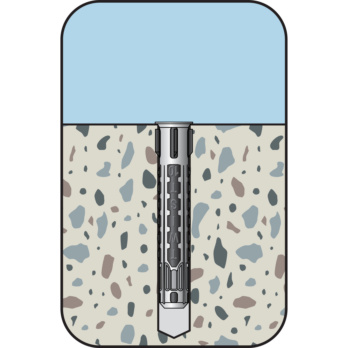

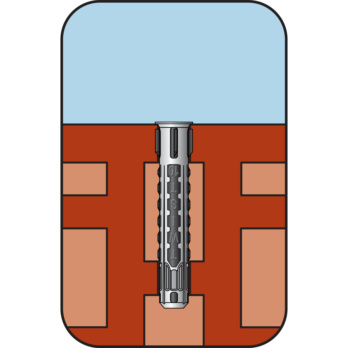

Inserting the anchor

Can be used with one finger without a hammer

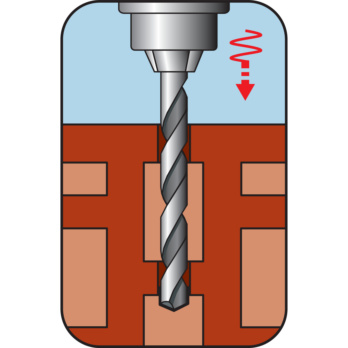

Drill the hole

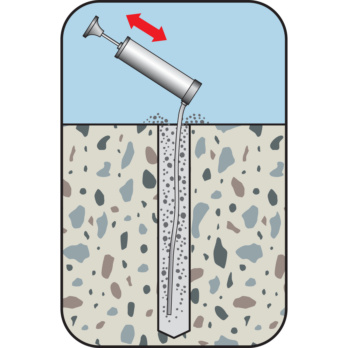

Remove drill cuttings from drill hole

Place anchors in drill hole

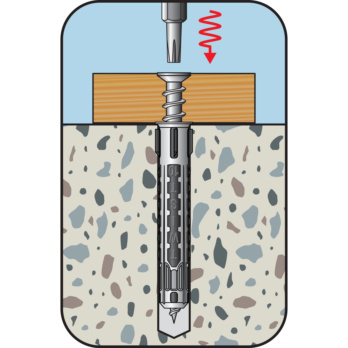

Screw in the screw flush through the attachment part

Drill the hole

Place anchors in drill hole

Screw in the screw flush through the attachment part

Drill the hole

Place anchors in drill hole

Screw in the screw flush through the attachment part

ETA-22/0877

Datasheets(X)

- Universal plastic anchor

- Can be used in concrete, solid brick, solid calcium silicate block, vertically perforated brick, hollow calcium silicate block, aerated concrete, plasterboard, gypsum fibreboard

- Suitable for attaching light to medium loads, such as curtain rails, wall shelves, lightweight hanging cabinets, picture frames, mirrors, lamps, cable ducts, cable clamps, electrical switches, washbasins, towel rails, information signs and motion detectors

- For attaching components in conjunction with a wood or chipboard screw

- Can be used outdoors or in wet rooms in conjunction with a stainless steel screw

Anchor diameter | 12 mm |

Material | Polypropylene - PP / polyamide - PA |

Colour | White, Anthracite |

Anchor length (l) | 66 mm |

Nominal drill-bit diameter (d 0) | 12 mm |

Drill hole depth (t) | 75 mm |

Edge clearance (a r) | 150 mm |

Embedding depth (h s) | 65 mm |

Min./max. required screw diameter | 8-10 mm |

Min./max. temperature conditions | -40 to 50 °C |

| Hollow-core prestressed concrete EN 206:2013+A1:2016 | ≥25 | ≥ C30/37 | 0,30 | 0,48 | 0,48 | 0,48 | 0,48 |

| ≥40 | ≥ C30/37 | 0,60 | 0,60 | 0,60 | 0,60 | 0,60 |

| Vertically perforated brick ≥ Hlz12 | 0,25 | 0,35 | 0,4 | 0,5 | 0,6 |

| Hollow calcium silicate block ≥ KSL12 | 0,5 | 0,7 | 1 | 1,4 | 1,6 |

| Autoclaved aerated concrete PB2; PP2 | 0,15 | 0,2 | 0,25 | 0,4 | 0,5 |

| Gypsum building panels ρ ≥ 0.85 kg/dm³ | 0,22 | 0,35 | 0,5 | 0,6 | 0,7 |

| Gypsum plasterboard dia. = 12.5 mm | 0,1 | 0,2 | 0,2 | - | - |

| Gypsum plasterboard dia. = 25 mm | 0,2 | 0,25 | 0,35 | - | - |

| Gypsum fibreboard dia. = 10 mm | 0,3 | 0,35 | 0,45 | - | - |

| Suitable screw diameters (metric) - solid and perforated construction materials | M4 | M5 | M6 | M8 | M10 |

| Suitable screw diameters (metric) - panel materials | M3 | M4 | M5 | - | - |

| Nominal drill dia. | d0 [mm] | 6 | 8 | 10 | 12 | 14 |

| Dia. of cutting edges | dcut ≤ [mm] | 6,4 | 8,45 | 10,45 | 12,5 | 14,5 |

| Drill hole depth | h1 ≥ [mm] | ls + 5 mm - tfix | ||||

| Embedment depth of the anchor sleeve | hnom [mm] | 35 | 45 | 55 | 65 | 75 |

| Through hole in the fixture | df ≤ [mm] | 5,5 | 6,5 | 8,5 | 10,5 | 12,5 |

| Effective anchorage depth | hnom [mm] | 55 | 65 | 75 | ||

| Masonry brick Mz, EN 771-1:2011+A1:2015 | ≥NF (≥240x115x71) | ≥ 1.8 | 10 | 0,34 | 0,42 | 0,42 |

| 12,5 | 0,42 | 0,57 | 0,57 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 20 | 0,71 | 1,00 | 1,00 | |||

| 25 | 0,85 | 1,28 | 1,28 | |||

| 35 | 1,28 | 1,57 | 1,57 | |||

| 45 | 1,71 | 1,85 | 2,00 | |||

| 54,8 | 1,85 | 2,00 | 2,14 | |||

| Vertically perforated brick HLz, EN 771-1:2011+A1:2015 | ≥2DF (≥240x115x113) | ≥1.2 | 10 | 0,21 | 0,42 | 0,57 |

| 12,5 | 0,25 | 0,57 | 0,71 | |||

| 15 | 0,34 | 0,57 | 0,71 | |||

| 20 | 0,42 | 0,71 | 0,71 | |||

| 24,1 | 0,57 | 0,71 | 0,71 | |||

| Solid calcium silicate block KS, EN 771-2:2011+A1:2015 | ≥NF (≥240x115x71) | ≥ 1.8 | 10 | 0,34 | 0,42 | 0,42 |

| 12,5 | 0,42 | 0,57 | 0,57 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 20 | 0,71 | 1,00 | 0,85 | |||

| 25 | 1,00 | 1,28 | 1,14 | |||

| 35 | 1,42 | 1,57 | 1,57 | |||

| 45 | 1,71 | 1,85 | 2,00 | |||

| 49,4 | 1,71 | 1,85 | 2,00 | |||

| Solid calcium silicate block KS, EN 771-2:2011+A1:2015 | ≥4DF (≥248x175x248) | ≥ 1.8 | 10 | 0,85 | 1,00 | 1,00 |

| 12,5 | 1,00 | 1,14 | 1,14 | |||

| 15 | 1,14 | 1,14 | 1,28 | |||

| 20 | 1,28 | 1,42 | 1,42 | |||

| 23,4 | 1,28 | 1,42 | 1,42 | |||

| Hollow calcium silicate block KS L, EN 771-2:2011+A1:2015 | ≥2DF (≥240x115x113) | ≥ 1.8 | 10 | 0,42 | 0,71 | 0,71 |

| 12,5 | 0,57 | 0,71 | 0,71 | |||

| 15 | 0,57 | 0,71 | 0,71 | |||

| 18,8 | 0,71 | 0,71 | 0,71 | |||

| Hollow calcium silicate block KS L, EN 771-2:2011+A1:2015 | ≥8DF (≥248x240x238) | ≥ 1.8 | 7,5 | - | 0,57 | 0,71 |

| 10 | - | 0,71 | 0,71 | |||

| Solid blocks made of lightweight concrete V and Vbl, EN 771-3:2011+A1:2015 | ≥NF (≥240x115x71) | ≥1.2 | 2,5 | 0,21 | 0,34 | 0,42 |

| 5 | 0,42 | 0,57 | 0,57 | |||

| 7,3 | 0,57 | 0,71 | 0,71 | |||

| Solid blocks made of lightweight concrete V and Vbl, EN 771-3:2011+A1:2015 | ≥NF (≥240x115x71) | ≥2.0 | 12,5 | 0,85 | 1,14 | - |

| 15 | 1,00 | 1,42 | - | |||

| 20 | 1,28 | 1,85 | - | |||

| 25 | 1,71 | 2,00 | - | |||

| 29 | 1,85 | 2,00 | - |

| Centric tension load1) for individual anchors or an anchor group | Concrete = C12/15 Nadm [kN] | 30 °C2)/50 °C3) | 0,48 | 0,8 | 1,6 | 2,2 | 2,4 |

| Concrete ≥ C16/20 Nadm [kN] | 30 °C2)/50 °C3) | 0,6 | 1,2 | 2,2 | 2,8 | 3,2 | |

| Shear load1) for individual anchors or an anchor group | Vadm | [kN] | 1,62 | 2,59 | 4,67 | 6,79 | 8,55 |

| Minimum member thickness | hmin | [mm] | 100 | 100 | 100 | 120 | 120 |

| Characteristic edge distance | ccr [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 | ||

| Characteristic spacing | scr [mm] | C12/15 | 110 | 110 | 130 | 140 | 155 |

| ≥ C16/20 | 80 | 80 | 90 | 100 | 110 | ||

| Minimum edge distance4) | cmin [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 | ||

| Minimum spacing4) | smin [mm] | C12/15 | 110 | 110 | 110 | 140 | 140 |

| ≥ C16/20 | 80 | 80 | 80 | 100 | 100 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!