ASSY® 3.0 brass-plated chipboard screw

ASSY 3.0 steel brass plated FT raised cntrsnk. AW

SCR-RSDCS-WO-AW10-(D1J)-3X17/14

ASSY 3.0

Register now and access more than 125,000 products

Brass-plated steel, full thread, raised countersunk head, AW drive

Connects the wood instead of splitting it

Asymmetric thread – faster speed

- Low screw-in torque

- High over-turning force

- Faster screwing in than conventional chipboard screws

- Double thread: 3.0–4.5 mm

AW drive – more power

- Optimum power transmission

- Very good snug fit

- Fast location

- Screw locates securely

- Almost no unscrewing of the bit

- No wobbling

- No damage to surface coating of screw

- Only 5 bit sizes for the diameters 3.0 to 12.0 mm

Ring thread – less tendency of the wood to split, very few blow-outs

- Minimal splitting forces, especially when screwing in at edges

- Reduction of the screw-in torque

- Blow-outs are avoided to a high degree thanks to the punching effect of the ring thread

- Ring thread: up to 4.5 mm

The brass-plated surface coating is only suitable for decorative purposes = no corrosion protection!

The screws are not suitable for outdoor use and for rooms subject to short-term or continuous high moisture levels! Please use ASSY® 3.0 A2 stainless steel screws in these cases.

To attach metals to wood, machine a precise cutout in the metal tab.

ASSY 3.0 chipboard screws are optimised for use in wooden materials. When used in plastic anchors, a reduction of the load-bearing capacity is possible. Therefore, we recommend only using screws without optimised thread tips (drill tip, mating thread, ring thread, serrated edge, self-clearing groove, etc.) in plastic dowels, e.g. Würth ASSY D, prefix number 0151 (countersunk head) and prefix number 0153 (pan head).

Available work documents:

Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA-11/0190

When using these screws, please follow ETA-11/0190 specifications.Datasheets(X)

CAD data (available after login)

For coniferous wood or wood-based materials made from softwood, make the fitting without a bradawl. To reduce the edge distances make a predrilled hole according to the core diameter.

When screwing into hardwood, drill according to ETA-11/0190.

| |

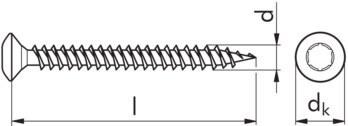

Nominal diameter (d) | 3 mm |

Length (l) | 17 mm |

Thread type | Wood screw thread |

Thread design | Full thread |

Thread form | Double start thread |

Thread length (lg) | 14 mm |

Core diameter | 1.95 mm |

Shape of tip | Tip with ring thread |

Angle of the tip | 20 Degree |

Head type | Raised countersunk head |

Head diameter (dh) | 6 mm |

Head height (k) | 2.4 mm |

Internal drive | AW10 |

Material | Hardened steel |

Surface | Brass plated |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

Product weight (per item) | 0.685 g |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Derived timber product, Hardwood, LVL, Softwood |

Area of application | Universal, Furniture, Body, Fitting |

Screw requiring approval | Yes |

Approval | ETA-11/0190 |

RoHS-compliant | Yes |