ASSY®plus A2 Decking construction screw

ASSYplus terrace sst A2 PT cntr cnsnk AW

SCR-TERRAC-DBIT-CTRHD-A2-AW20-5,5X40/18

Art.-no. 0166115540

EAN 4052712336133

Register now and access more than 125,000 products

Precise positioning and no splitting

Precise positioning of the screw is no problem at all thanks to its centring drilling tip, which was specially designed for this purpose. The drilling cutting edges guarantee perfect drilling performance, just like a Forstner bit. They also prevent irritating splitting or rupturing of the wood.

Clean and easy countersinking

Countersinking the small countersunk head is clean and easy, thanks to its small diameter. The under-head milling pockets pick up protruding chips. However, with tropical hardwood, countersinking of the surface is recommended, as these types of wood have very short chips.

Extremely robust

The grooved shaft provides for additional screw strength as austenitic stainless steel (A2/A4) cannot be hardened. This virtually eliminates the possibility of the screw tearing off.

AW drive for optimum locating and power transfer

The AW drive guarantees an excellent fit of the bit in the screw drive. This prevents wobbling impacts and sliding of the bit from the screw while screwing in.

Screwing down hardwood patio boards

Preliminary tests are required for hardwood. Pre-drilling of the wood may be necessary depending on the density and moisture level of the wood. It is recommended that the processing device be operated at a low speed.

When using these screws, the ETA-11/0190 specifications must be observed.

Available work documents:

Timber dimensioning software, load tables and detailed processing instructions can be found on the service page www.wuerth.de/assy.

ETA-11/0190

Datasheets(X)

CAD data (available after login)

The range of applications of the various stainless steels is contained in the following ISER (German Information Office for Rustproof Stainless Steel, Non-Rusting Steels for Various Environmental Conditions, www.edelstahl-rostfrei.de, Information Sheet 828) table. Rustproof stainless steels (e.g. material no. 1.4016) are recommended there for use in atmospheric processes only for use in a rural environment, and here as well only with great restrictions. We therefore recommend only using austenitic stainless steels for outdoor applications, taking the environmental conditions into account. Stainless steel A4 is especially suitable for use in an industrial atmosphere and for use near the sea.

| |

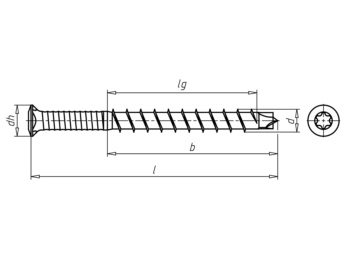

Nominal diameter (d) | 5.5 mm |

Length (l) | 40 mm |

Thread length (lg) (lg) | 18 mm |

Screw-thread length with drill tip (b) (b) | 22.5 mm |

Head type | Raised countersunk head |

Head details | Milling pockets |

Head diameter (dh) | 7.7 mm |

Head height (k) | 3.4 mm |

Internal drive | AW20 |

Thread type | Wood screw thread |

Thread design | Partial thread |

Design | With shaft |

Thread form | Single start thread |

Core diameter | 3.6 mm |

Shape of tip | Drilling tip |

Material | Stainless steel A2 |

Surface | Plain |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 45 Degree |

Suitable for use in the following materials | Board ply wood (BSP), Wood, Derived timber product, Hardwood, LVL, Softwood |

Area of application | Outdoors, Balcony, Element construction, Façades, Wet areas, Timber construction, Timber panel construction, Structural woodwork, Play equipment, Board walk, Terrace, Fence |

Approval | ETA-11/0190 |

Product weight (per item) | 3.656 g |

RoHS-compliant | Yes |

| Steel quality Short name | Material no. | Environment | ||||||||||||

| Country | City | Industrial | Close to the sea | |||||||||||

| N | M | H | N | M | H | N | M | H | N | M | H | |||

| X1NiCrMoCu25-20-5 | 1.4539 | Würth HCR | x | x | x | x | x | x | x | x | + | x | x | + |

| X5CrNiMo17-12-2 | 1.4401/1.4578 | Würth A4 | x | x | x | x | + | + | + | + | (+) | + | + | (+) |

| X5Cr-Ni18-10 | 1.4301/1.4567 | Würth A2 | + | + | + | + | + | (+) | (+) | (+) | - | + | (+) | - |

| X6Cr17 | 1.4016 | Many competitors | (+) | (+) | (+) | (+) | - | - | (+) | - | - | - | - | - |

| Stainless steels for various ambient conditions (www.edelstahl-rostfrei.de, Information Sheet 828) N= lowest corrosion load within the respective environment, indicated e.g. by low temperatures and low humidity M= medium corrosion load within the respective environment H= highest corrosion load within the respective environment, e.g. due to continuous high humidity, high ambient temperatures, particularly aggressive air pollution x= meets the requirements in principle, however, cheaper steels may also be sufficient += probably best material choice in terms of corrosion resistance and costs (+)= adequate performance as long as certain precautionary steps are taken. Smooth surfaces and regular cleaning are required in particular -= heavy corrosion expected | ||||||||||||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!