ASSY®plus VG 4 CSMP construction screw Steel zinc plated full thread countersunk milling pocket head

ASSYplus VG 4 CH steel zn FT cs mill. pocket RW

SCR-CSMP-WO-VG-RW50-(A3K)-12X360/319

Art.-no. 0150112360

EAN 4061975609724

Register now and access more than 125,000 products

Ideal power transmission thanks to RW drive

- More power due to larger contact area at the bit

- More stability, one-handed working, precise positioning due to the tight-fit recess and perfect fit of the bit

- Fewer bit changes, one bit for many screw diameters

- Compatibility with previous AW drive

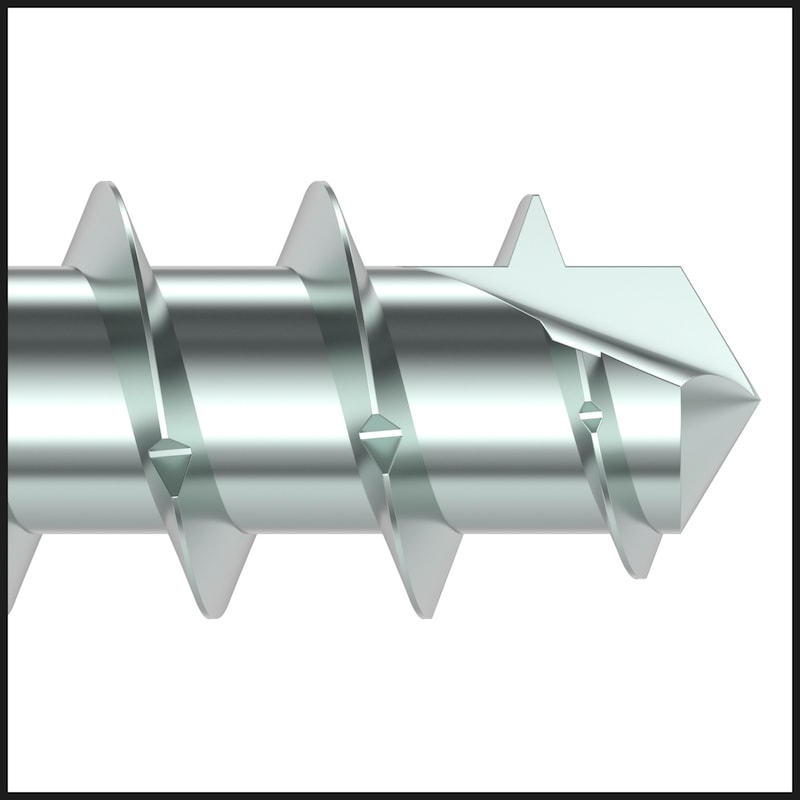

Clean countersinking in softwood or wood material

- Easy countersinking of screw head in wood thanks to optimised milling pockets

- No chipping in coated chipboards due to improved milling effect and increased number of milling pockets up to ∅ 4.5 mm

- Perfect fit of 90° head in fitting parts with metal countersinks

Visually appealing countersunk finish in wood-wood applications or precise countersunk finish in metal-wood applications thanks to innovative milled pockets

- Optimum balance between pulling together and countersinking

- Perfect countersinking in coated chipboard

- Clean finish of the countersunk head in solid wood

- Braking effect on metal and milling effect on wood

- Optimised number of milled pockets depending on the application

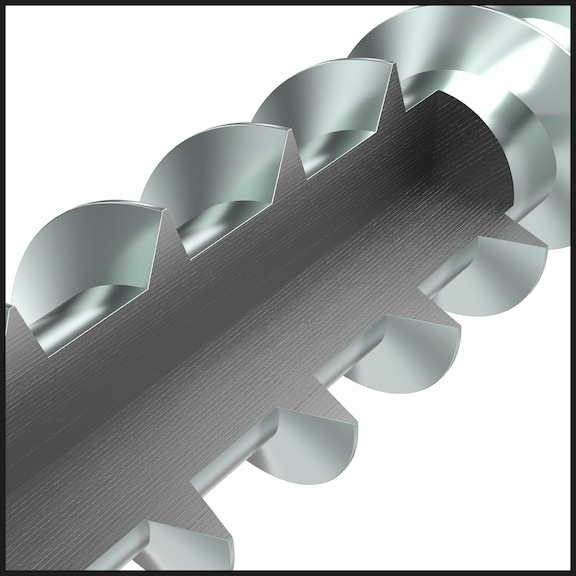

Highest power transmission in the tensile and compressive direction

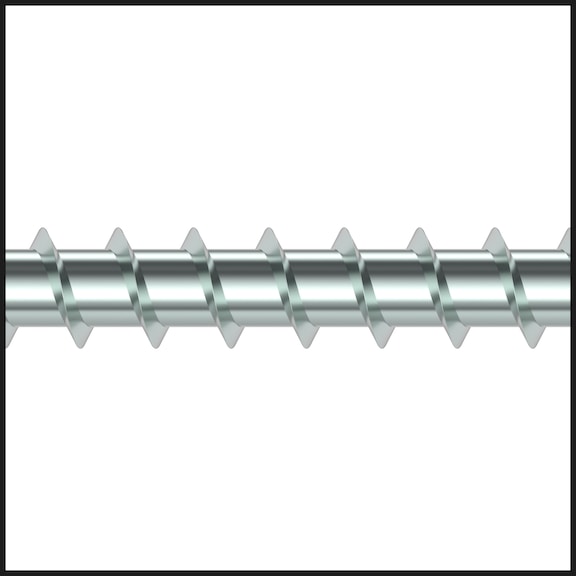

- Symmetrical high-performance thread matched to the pre-drilling performance of the drill bit tip

- For high-load wood/wood connections regardless of the load direction

Compact screw connections and small material cross-sections due to effective drill bit tip

- Extremely short permitted edge distances e.g. 3xd, making ASSY screws ∅ 8 mm usable for beam widths 60 mm

- No pre-drilling required

- The wood does not split and rupture

- Little run-off of long screws

High strength values and ductility

- Adjusted heat treatment guarantees high strength values and high ductility

- We recommend using the Würth software or the corresponding design aids for planning and dimensioning your assembly. Use the Würth timber construction software for dimensioning of ASSY screws from a diameter of 5 mm

- Do not use for screw applications with direct exposure to the elements or in humid rooms with atmospheres containing chlorine gas

- ASSY 4, ASSYplus 4 and ASSYplus 4 FT chipboard screws are optimised for use in wood and wood materials. For applications in plastic anchors where load capacity can also be reduced, use only screws without an optimised thread tip (tip with milling ribs, drill tip, self-clearing groove etc.), such as the ASSY D screws with countersunk head or pan head

ETA-11/0190 approved

The requirements of the European Technical Approval (ETA) must be observed

Datasheets(X)

Universally applicable for high-load-bearing connections in structural wood construction for connections loaded on tensile or pressure steel-wood connections

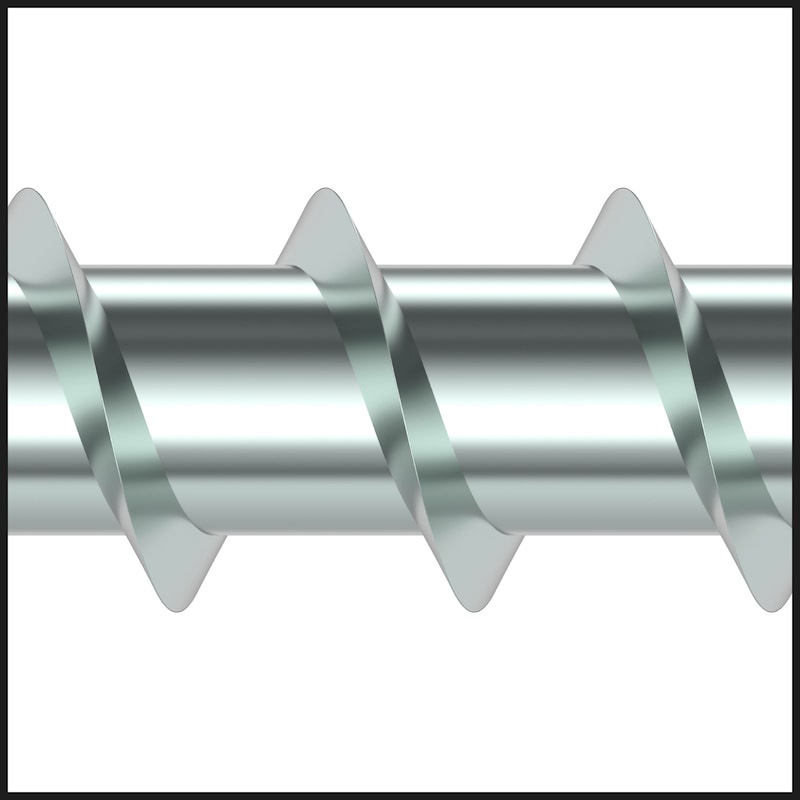

The full thread starting immediately below the head allows for e.g. fitting/metal/wood or sheet material/wood connections designed for tensile forces with high load-bearing capacity. Greater screw pull-out force is achieved by the maximum thread length.

For applications in utilisation class 1 and utilisation class 2 (from ∅ > 4 mm)

- High-quality surface protection, zinc, blue-passivated chromium(VI)-free 8 µm layer thickness

- Suitable for use in utilisation class 1 (interior) and from a ∅ > 4 mm in utilisation class 2 (wet area or covered outdoor area) according to EN 1995-1-1:2010-12 + DIN SPEC 1052-100:2013-08

- The requirement of classification T2/C2 is fulfilled in accordance with prEN 14592:2017 (D)

- ASSY screws are approved for quasi-static loads

- For optimum use of the screw, the right-size RW bit must be used

- In the case of transverse compression reinforcements, a pressure distribution plate must be inserted between the support bearing and the screw heads for even load transmission. The screw head must be flush with the pressure distribution plate. Use full-thread screws with a countersunk head if suitable. The steel plate thickness must be dimensioned in such a way that a uniform load distribution on the screws is guaranteed

- For the reinforcement of wooden components at a right angle to the fibre under tensile load, at least 2 screws must be used. If the screw-in depth is least 20 x d above or below the crack-prone area, with d being the outer thread diameter of the screw, only one screw may be used

- If countersunk head screws are used for a metal-to-wood mounting, the metal to be connected must be provided with suitable countersunk holes

- For a load-bearing wood-metal connection, ASSY screws must be tightened to a specific torque value. Tightening torque = required prevailing torque x 1.2 < 90% of the breaking torque

- For long screws arranged in a cross shape or in a screw block with narrow edge clearances, it is advisable to drill pilot holes or use a screw-in aid to avoid intersecting of the screws

| |

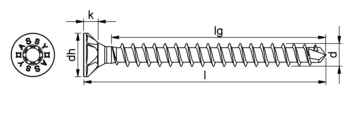

Nominal diameter (d) | 12 mm |

Length (l) | 360 mm |

Thread length (lg) (lg) | 319 mm |

Screw-thread length with drill tip (b) (b) | 319 mm |

Head type | Countersunk milling pocket head |

Head details | Milling pockets |

Head diameter (dh) | 22.5 mm |

Head height (k) | 7 mm |

Internal drive | RW50 |

Thread type | Wood screw thread |

Thread design | Full thread |

Thread form | Single start thread |

Core diameter | 7.1 mm |

Shape of tip | Drilling tip |

Material | Hardened steel |

Surface | Zinc plated |

Max. screw-in angle | 90 Degree |

Min. screw-in angle | 0 Degree |

Suitable for use in the following materials | Wood, Derived timber product, Softwood, Board ply wood (BSP), Hardwood, LVL |

Area of application | Structural woodwork, Lateral compression reinforcement, Metal wood connections, Timber construction |

Additional accessory | Bit lock |

Approval | ETA-11/0190 |

Product weight (per item) | 152.000 g |

RoHS-compliant | Yes |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!