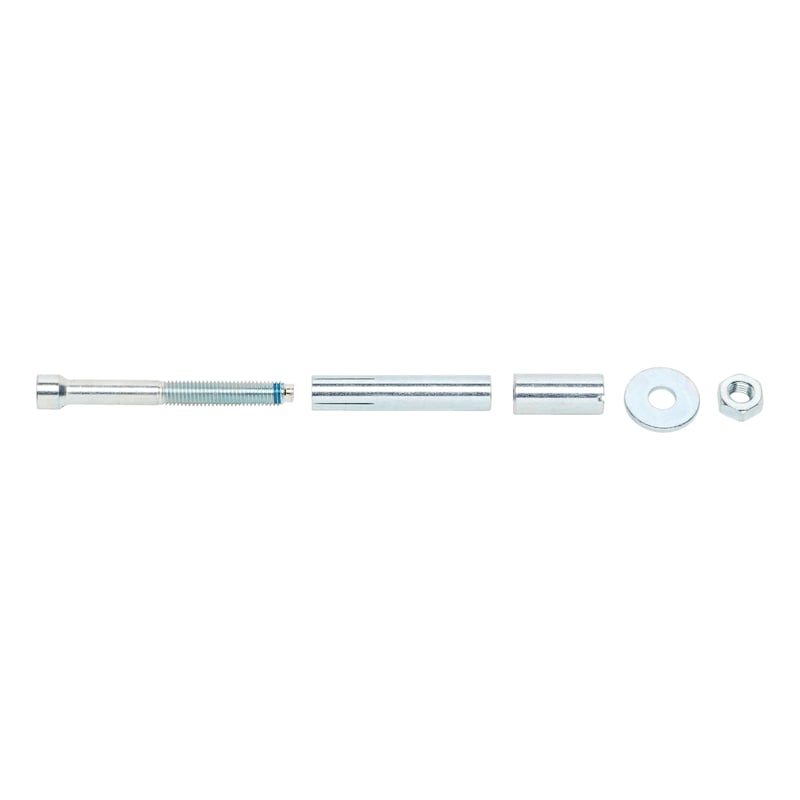

Aerated concrete anchor W-PA

Aerated concrete anchor, W-PA type A

ANC-(W-PA/A)-(A2K)-20-M10X94

Art.-no. 0905711020

EAN 4011231852623

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Heavy-duty anchor with male thread (type A) for individual attachment in aerated concrete. With technical approval. Steel, zinc plated

- High permissible loads for maximum safety

- Quick anchor insertion — minimal installation costs

- Immediate load-bearing capacity — no waiting

- The positive locking anchoring is largely free of expansion pressure and is achieved without expensive and complicated undercutting tools.

Assembly with and without tools possible

Mechanical application with special tool for SDS mount also possible — uses only the impact action of the hammer drill (min. 3 kg).

Proof of Performance

- Z-21.1-1983 General technical approval for: tension zone (cracked aerated concrete) and compression zone (non-cracked aerated concrete); lightweight ceiling cladding and suspended ceilings in accordance with DIN 18168-1:1981-10 in reinforced roof and ceiling panels, and for structurally comparable anchorages (see technical approval for maximum load)

- Fire resistance: F90, F120 (M6–M12)

Notice

The anchors may only be fixed in unplastered, uncoated masonry walls

Knock in conical threaded bolt with setting tool without predrilling until flush

Knock in conical threaded bolt with setting tool without predrilling until flush

Expansion sleeve with slots

attach forwards to

ground

Knock in expansion sleeve with setting tool until flush

Knock in expansion sleeve with setting tool until flush

Mount component, apply torque

Mount component, apply torque

- Z-21.1-1983 General technical approval for: tension zone (cracked aerated concrete) and compression zone (non-cracked aerated concrete); lightweight ceiling cladding and suspended ceilings in accordance with DIN 18168-1:1981-10 in reinforced roof and ceiling panels, and for structurally comparable anchorages (see technical approval for maximum load)

- Fire resistance: F90, F120 (M6–M12)

Product information

Datasheets(X)

CAD data (available after login)

Application area

- Heavy-duty anchor for non-reinforced aerated concrete, strength classes PB2, PB4 and PB6, and in reinforced aerated concrete, strength classes P 3.3 and P 4.4

- Suitable for attaching metal structures, metal profiles, suspended ceilings, plumbing pipes, ventilation lines, base plates, brackets, railings, grilles, machinery, wooden structures, beams, purlins, supports etc. (see Anchor technology for industries)

- For anchoring with primarily static loads

- Use for components in dry, enclosed areas

- Not suitable for wet rooms with an atmosphere containing chlorine (public swimming pools etc.)

Anchor diameter | 10 mm |

Embedding depth (h s) | 70 mm |

Max. attachment height (d a) | 20 mm |

Hole diameter in component (d Bau) | 12 mm |

Material | Steel |

Surface | Zinc plated |

| Performance data | ||||||

| Anchor diameter [mm], conical bolt | M6 | M8 | M10 | M12 | ||

| Permissible load Tensile, shear, oblique pull under any angle (zinc plated steel Zn) | Pressure zone (non-cracked concrete) | Fperm [kN] PB2 | 0,40 | 0,40 | 0,60 | 0,60 |

| Fperm [kN] PB4 | 0,80 | 0,80 | 1,20 | 1,20 | ||

| Tensile zone (cracked aerated concrete) | Fperm [kN] P3.3 | 0,60 | 0,60 | 0,80 | 0,80 | |

| Fperm [kN] P4.4 | 0,80 | 0,80 | 1,20 | 1,20 | ||

| Ceiling applications in cracked aerated concrete in tensile zone range of roof and ceiling panels | Fperm [kN] P3.3 | 0,60 | 0,60 | 0,80 | 0,80 | |

| Fperm [kN] P4.4 | 0,80 | 0,80 | 1,20 | 1,20 | ||

| Anchor applications when using pairs of anchors (per pair) | Fperm [kN] P3.3 | 0,60 | 0,60 | 0,80 | 0,80 | |

| Fperm [kN] P4.4 | 0,80 | 0,80 | 1,20 | 1,20 | ||

| Permissible bending moments (type A) Zinc plated steel Zn | Mperm. [Nm] | 6,97 | 10,70 | 21,40 | – | |

| Fire resistance duration | ||||||

| Anchoring of light ceiling coverings and joist constructions (DIN 18168): Permissible load per anchor in aerated concrete of strength class ≥ P3.3 | Permissible F [kN] – F 90 | 0,35 | 0,45 | 0,80 | 0,80 | |

| Permissible F [kN] – F 120 | 0,30 | 0,35 | 0,75 | 0,75 | ||

| Anchoring façade cladding: 1) Admissible load per anchor in autoclaved aerated concrete of strength class ≥ PB2, PP2 and ≥ P3.3 | Permissible F [kN] – F 90 | 0,35 | 0,45 | 0,80 | 0,80 | |

| Permissible F [kN] – F 120 | 0,30 | 0,35 | 0,75 | 0,75 | ||

| 1) It must be possible to redistribute the load to at least one adjacent fixing point. | ||||||

| Characteristic values | |||||

| Spacing | a ≥ [mm] | 100 | 100 | 100 | 100 |

| Edge distance | ar ≥ [mm] | 150 | 150 | 150 | 150 |

| Tightening torque | MD[Nm] | 3 | 5 | 8 | 8 |

| Embedment depth (Type A / Type i) | hS [mm] | 70/70 | 70/70 | 70/80 | -/80 |

| Minimum member thickness | d ≥ [mm] | 175 | 175 | 175 | 175 |

| Nominal drill diameter | ddrill [mm] | do not pre-drill | do not pre-drill | do not pre-drill | do not pre-drill |

| Hole diameter in the member (type A/type i) | dconstr ≤ [mm] | 7/7 | 9/9 | 12/12 | -/14 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!