Bonded anchor glass capsule W-VPZ

Compound anchor glass cartridge W-VPZ

ANC-(W-VPZ)-10X90

Register now and access more than 125,000 products

- 2C glass capsule with vinyl ester resin (styrene-free) and hardener

- Can be used all year round, even in frost and heat (temperature in concrete: -20 °C to +40 °C)

- Quick and economical installation due to the pre-portioned mortar quantities

- Rapid curing means hardly any waiting time until load capacity

- Drill hole cleaning does not require compressed air

- Allows interruption to work after inserting the mortar capsule into the drill hole, as the chemical reaction only begins after the anchor rod has been inserted

- Hardened composite mortar seals the drill hole against water

- If a drill hole is created with a dust extraction drill bit, subsequent drilling hole cleaning can be omitted (dust load is minimised)

- No plastic waste

- Minimum shelf life 36 months

- European Technical Assessment ETA-21/0168: Fixing point + cracked and non-cracked concrete (anchor rod W-VD-A)

- Leak test under the influence of water pressure up to 7 bar

- Fire resistance: NRk,fi(30), NRk,fi(60), NRk,fi(90), NRk,fi(120)

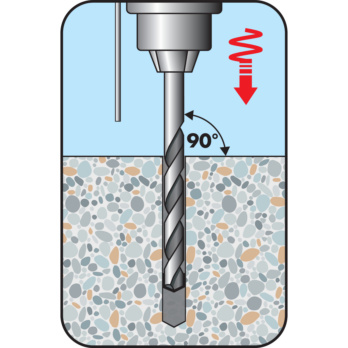

Create the drill hole

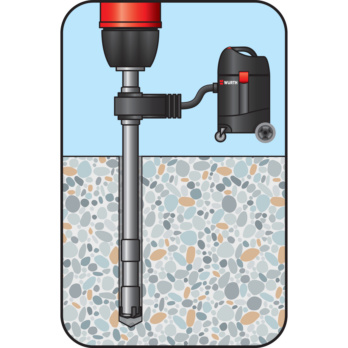

Make the drill hole with the Würth hollow drill bit. Hole cleaning can be dispensed with

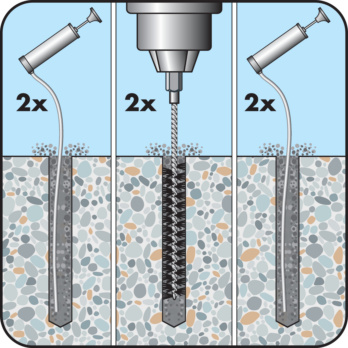

Clean the drill hole: 2x blow-out/2x brush-out/2x blow-out

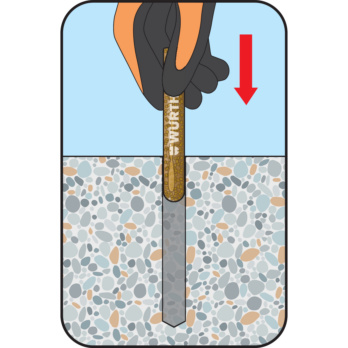

Place the capsule in the bore hole

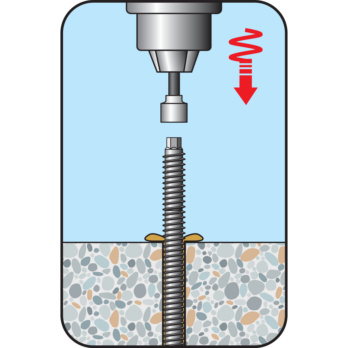

Set anchor rod W-VD-A turning/with impact

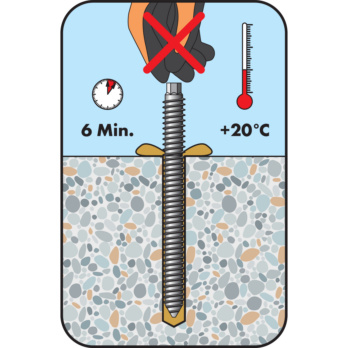

Observe the curing time. Do not move or load the anchor rod until it is completely cured

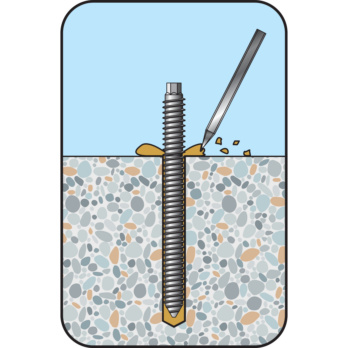

Remove extruded mortar

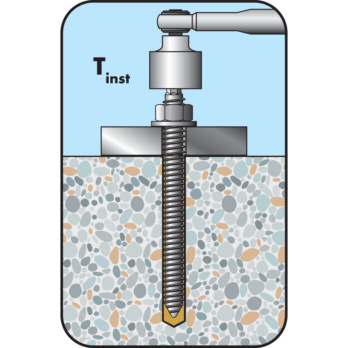

Install attachment and apply torque Tinst

| Minimum curing times | |

| Concrete temperature Minimum curing time | Minimum curing time |

| -20°C to -16°C | 17 hours |

| -15°C to -11°C | 7 hours |

| -10°C to -6°C | 4 hours |

| -5°C to -1°C | 3 hours |

| 0°C to +4°C | 50 min |

| +5°C to +9°C | 25 min |

| +10°C to +19°C | 15 min |

| +20°C to +29°C | 6 min |

| +30°C to +40°C | 6 min |

| Cartridge temperature | -15°C to +40°C |

- European Technical Assessment ETA-21/0168: Fixing point + cracked and non-cracked concrete (anchor rod W-VD-A)

- Leak test under the influence of water pressure up to 7 bar

- Fire resistance: NRk,fi(30), NRk,fi(60), NRk,fi(90), NRk,fi(120)

Datasheets(X)

- Anchoring with European Technical Assessment in cracked and uncracked concrete

- The anchor may be used for anchorages with static loads (e.g. tare weight, fittings, stored materials) or quasi-static activity

- Suitable for fastening metal structures, metal profiles, brackets, base plates, supports, wooden structures, railings, stairs etc.

The anchor rod is set in a rotating stroke, the two mortar components are mixed by the rotation movement

- Blow out the drill hole completely at least twice from the bottom of the drill hole using a blow-out pump or compressed air

- Brush out the drill hole twice with the WIT-RMB cleaning brush

- Blow out the drill hole completely at least twice from the bottom of the drill hole using a blow-out pump or compressed air

- The drill hole can be produced with a suction drill, which means that additional drilling hole cleaning can be omitted

Effective anchoring depth (h ef) | 90 mm |

Suitable for anchor rod | M10, M6 IT |

Nominal drill-bit diameter (d 0) | 12 mm |

Drill hole depth (h 0) | 90 mm |

Suitable cleaning-brush diameter | 12 mm |

Approval | ETA-21/0168 |

Min./max. processing temperature | -15 to +40 °C |

Torque during anchoring (T inst) | 20 Nm |

Shelf life from production/conditions | 36 Month / cool and dry storage area, 5°C to 25°C |

Minimum component thickness (h min) | 120 mm |

Min. centre-to-centre distance (s min) | 50 mm |

Centre-to-centre distance (s cr, N) | 270 mm |

Min. edge clearance (c min) | 45 mm |

Edge clearance (c cr, N) | 135 mm |

| Cracked and uncracked concrete: Performance data, individual anchor without the influence of the edge distance (c ≥ 10 hef) | |||||||

| Temperature range: 24°C1)/40°C2) (temperature ranges 50°C/80°C, see ETA-21/0168) Base material: Dry and wet concrete Concrete compressive strength: C20/25 Drill hole cleaning: 2x blow out/2x brush out/2x blow out or dust extraction drill bit | |||||||

| Anchor diameter | M8 | M10 | M12 | M16 | M20 | ||

| Effective anchorage depth | hef [mm] | 80 | 90 | 110 | 125 | 170 | |

| Cracked concrete | |||||||

| Admissible centric tension load3), (individual anchor without the influence of the edge distance and without dense reinforcement) | Zinc-plated steel, 5.8 | Nadm [kN] | 4,0 | 7,3 | 11,5 | 18,7 | 31,7 |

| Zinc-plated steel, 8.8 | Nadm [kN] | 4,0 | 7,3 | 11,5 | 18,7 | 31,7 | |

| A4 and HCR stainless steel | Nadm [kN] | 4,0 | 7,3 | 11,5 | 18,7 | 31,7 | |

| Admissible shear load3 (individual anchor without the influence of the edge distance and without dense reinforcement) | Zinc-plated steel, 5.8 | Vadm [kN] | 6,3 | 9,7 | 14,3 | 26,9 | 41,7 |

| Zinc-plated steel, 8.8 | Nadm [kN] | 8,6 | 13,1 | 19,4 | 35,9 | 56,0 | |

| A4 and HCR stainless steel | Vadm [kN] | 6,0 | 9,2 | 13,7 | 25,2 | 39,4 | |

| Uncracked concrete | |||||||

| Admissible centric tension load3), (individual anchor without the influence of the edge distance and without dense reinforcement) | Zinc-plated steel, 5.8 | Nadm [kN] | 8,0 | 13,8 | 20,0 | 28,0 | 44,4 |

| Zinc-plated steel, 8.8 | Nadm [kN] | 8,0 | 14,6 | 21,4 | 28,0 | 44,4 | |

| A4 and HCR stainless steel | Nadm [kN] | 8,0 | 14,6 | 21,4 | 28,0 | 44,4 | |

| Admissible shear load3 (individual anchor without the influence of the edge distance and without dense reinforcement) | Zinc-plated steel, 5.8 | Vadm [kN] | 6,3 | 9,7 | 14,3 | 26,9 | 41,7 |

| Zinc-plated steel, 8.8 | Nadm [kN] | 8,6 | 13,1 | 19,4 | 35,9 | 56,0 | |

| A4 and HCR stainless steel | Vadm [kN] | 6,0 | 9,2 | 13,7 | 25,2 | 39,4 | |

| 1) Maximum long-term temperature 2) Maximum short-term temperature 3) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. The tensile load portion "continuous load" (including constant loads and constant portions of variable loads) is less than 60% of the total tensile load. For information on combining tensile and shear loads, on the influence of the edge distance, and on anchor groups, please see standard EN 1992-4. | |||||||

| Assembly data | ||||||

| Nominal drill ∅ | d0 [mm] | 10 | 12 | 14 | 18 | 22 |

| Drill hole depth/effective anchorage depth | h0/hef [mm] | 80 | 90 | 110 | 125 | 170 |

| Minimum edge distance1) | cmin [mm] | 40 | 45 | 45 | 50 | 55 |

| Minimum axis distance2) | smin [mm] | 40 | 50 | 60 | 75 | 90 |

| Minimum member thickness | hmin [mm] | 110 | 120 | 140 | 160 | 220 |

| Through hole in the component being connected | df ≤ [mm] | 9 | 12 | 14 | 18 | 22 |

| Torque while installing anchor | Tinst ≤ [Nm] | 10 | 20 | 40 | 80 | 150 |

| Nut width across flats | AF [mm] | 13 | 17 | 19 | 24 | 30 |

| Anchor rod width across flats | AF [mm] | 5 | 6 | 8 | 12 | 14 |

| 1) If the characteristic edge distance is not met, the maximum load capacity is reduced. The smallest possible edge distance is cmin 2) If the characteristic axis distance is not met, the maximum load capacity is reduced. The smallest possible axis distance is smin | ||||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!