Combination joist hanger 1.5 mm One piece

Combi joist hanger 1.5 mm

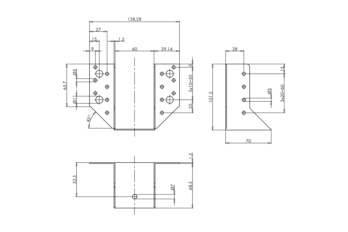

JOISTHNG-COMBI-(EXCRANKED)-60X130X1,5

Register now and access more than 125,000 products

Reduced weight for easy handling

European Technical Approval ETA-08/0184

Diameter of bolts/screws may not be any smaller than the diameter of the hole minus 1 mm. The upper bolts must be fitted with a washer in line with DIN EN ISO 7094.

The respective basic conditions of the applicable anchor approval must be observed.

European Technical Approval ETA-08/0184

Datasheets(X)

Load-bearing connections of timber joists to wood, concrete or steel

Suitable fasteners:

- Ribbed nail in line with EN 14592: 4.0x25–100 mm (fax, k ≥ 50 × 10-6 × ρk2 (N/mm²))

- ASSY joist hanger screw in line with ETA 11/1090: 5.0x25–50 mm

- Wood screw in line with EN 14592: 5.0x25–50 mm

- ASSY 3.0 combination screw in line with ETA 11/0190: d = 10 mm

- Bolts in accordance with manufacturer's specifications: M10

- Recommended dowels for anchoring in concrete: W-BS; W-FAZ; W-VIZ; W-VM 250

| |

Width x height | 60 x 130 mm |

Thickness | 1.5 mm |

Number of D 5 mm holes in subcarrier nJ + main carrier nH | 11 + 20 PCS |

Number of D 11 mm holes in subcarrier nJ + main carrier nH | 0 + 4 PCS |

Weight | 239 g |

Depth of underside | 70 mm |

Material | Steel |

Surface | Hot dip galvanized |

Width of wing on nut | 39 mm |

Approval | ETA-08/0184 |

Material designation | S250GD |

Material standard | DIN EN 10346:2009 |

Number of pieces | 1 PCS |

Depth of upper side | 37 mm |

| Art. no. | Format in mm | Complete nailing | Partial nailing | ||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | ||||||||

| 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | ||

| 5390 060 100 | 60/100 | 21,5 | 22,9 | 17,2 | 18,3 | 8,96 | 9,85 | 12,9 | 13,8 | 8,60 | 9,17 | 4,48 | 4,93 |

| 5390 060 120 | 60/120 | 25,8 | 27,5 | 21,5 | 22,9 | 9,93 | 10,9 | 17,2 | 18,3 | 12,9 | 13,8 | 5,96 | 6,51 |

| 5390 060 130 | 60/130 | 27,9 | 29,8 | 23,6 | 25,2 | 10,3 | 11,2 | 17,2 | 18,3 | 12,9 | 13,8 | 5,51 | 6,00 |

| 5390 060 160 | 60/160 | 34,4 | 36,7 | 30,1 | 32,1 | 11,1 | 12,0 | 21,5 | 22,9 | 17,2 | 18,3 | 6,35 | 6,87 |

| 5390 060 190 | 60/190 | 40,8 | 43,6 | 36,5 | 39,0 | 11,6 | 12,5 | 23,6 | 25,2 | 19,3 | 20,6 | 6,01 | 6,48 |

| 5390 070 125 | 70/125 | 25,8 | 27,5 | 21,5 | 22,9 | 11,1 | 12,3 | 17,2 | 18,3 | 12,9 | 13,8 | 6,69 | 7,36 |

| 5390 080 120 | 80/120 | 25,8 | 27,5 | 21,5 | 22,9 | 12,2 | 13,5 | 17,2 | 18,3 | 12,9 | 13,8 | 7,33 | 8,12 |

| 5390 080 140 | 80/140 | 30,1 | 32,1 | 25,8 | 27,5 | 13,3 | 14,6 | 17,2 | 18,3 | 12,9 | 13,8 | 6,42 | 7,04 |

| 5390 080 150 | 80/150 | 32,2 | 34,4 | 27,9 | 29,8 | 13,7 | 15,0 | 19,3 | 20,6 | 15,0 | 16,0 | 7,27 | 7,96 |

| 5390 080 180 | 80/180 | 38,7 | 41,3 | 34,4 | 36,7 | 14,6 | 15,9 | 21,5 | 22,9 | 17,2 | 18,3 | 7,00 | 7,60 |

| 5390 080 210 | 80/210 | 45,1 | 48,1 | 40,8 | 43,6 | 15,3 | 16,5 | 25,8 | 27,5 | 21,5 | 22,9 | 7,84 | 8,48 |

| 5390 100 140 | 100/140 | 30,1 | 32,1 | 25,8 | 27,5 | 15,4 | 17,1 | 17,2 | 18,3 | 12,9 | 13,8 | 7,50 | 8,31 |

| 5390 100 160 | 100/160 | 34,4 | 36,7 | 30,1 | 32,1 | 16,5 | 18,2 | 21,5 | 22,9 | 17,2 | 18,3 | 9,45 | 10,4 |

| 5390 100 170 | 100/170 | 36,5 | 39,0 | 32,2 | 34,4 | 17,0 | 18,7 | 21,5 | 22,9 | 17,2 | 18,3 | 8,87 | 9,75 |

| 5390 100 200 | 100/200 | 43,0 | 45,8 | 38,7 | 41,3 | 18,1 | 19,7 | 25,8 | 27,5 | 21,5 | 22,9 | 10,0 | 11,0 |

| 5390 120 160 | 120/160 | 34,4 | 36,7 | 30,1 | 32,1 | 18,6 | 20,7 | 21,5 | 22,9 | 17,2 | 18,3 | 10,6 | 11,8 |

| 5390 120 180 | 120/180 | 38,7 | 41,3 | 34,4 | 36,7 | 19,7 | 21,9 | 21,5 | 22,9 | 17,2 | 18,3 | 9,51 | 10,5 |

| 5390 120 190 | 120/190 | 40,8 | 43,6 | 36,5 | 39,0 | 20,2 | 22,3 | 23,6 | 25,2 | 19,3 | 20,6 | 10,5 | 11,6 |

| 5390 140 180 | 140/180 | 38,7 | 41,3 | 34,4 | 36,7 | 21,7 | 24,2 | 21,5 | 22,9 | 17,2 | 18,3 | 10,5 | 11,7 |

| Measured load capacity value: Fi,Rd = Fi,Rk × kmod/ƳM For combined effect of action, the following condition must be met: (Fy, Ed /Fy, Ed)^2+ (Fz, Ed/Fz, Rd)^2 ≤1 | |||||||||||||

| Notes: · Load-bearing capacities are valid for wood with a characteristic density Ƥk = 350 kg/m³. · Nail load-bearing capacities according to EN 1995-1-1. Pull-out capacity for load-bearing capacity class 3 according to DIN EN 1995-1-1/NA. · Würth ASSY joist hanger screws according to ETA-11/0190. · The force Fz acts in the centre of the secondary beam. The force Fy acts on the top edge of the joist hanger. In the case of a load application below the top edge of the joist hanger, the table values can be used on the safe side. At a different spacing of the force Fy, the load-bearing capacity can be determined according to ETA-08/0184. · Partial nailing: On the main support, the fasteners must be placed in the rows closest to the secondary beam. On the secondary beam, the fasteners must be evenly spaced over the height of the beam. The fasteners must always be arranged in the upper and lower holes. · The main support must be secured to prevent torsion. · The transverse tensile capacity of the main support must be investigated separately. · For one-sided connections on the main support, the offset moment must be taken into account. · The regulations of ETA-08/0184 must be observed. | |||||||||||||

| NOTE: These are guides for planning purposes. The values must be calculated for each project by authorised persons. | |||||||||||||

| CHARACTERISTIC LOAD-BEARING CAPACITIES IN kN OF WÜRTH COMBINATION JOIST HANGERS 1.5 MM (ETA-08/0184) WITH WÜRTH ANCHOR NAILS | |||||||||||||

| Art. no. | Format in mm | Complete nailing | Partial nailing | ||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | ||||||||

| 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | ||

| 5390 060 100 | 60/100 | 12,4 | 18,9 | 7,40 | 11,9 | 4,80 | 7,19 | 6,30 | 9,76 | 4,57 | 7,32 | 2,40 | 3,59 |

| 5390 060 120 | 60/120 | 17,7 | 25,8 | 11,9 | 18,8 | 5,66 | 8,29 | 8,97 | 13,6 | 7,13 | 11,2 | 3,40 | 4,98 |

| 5390 060 130 | 60/130 | 20,6 | 27,9 | 14,5 | 22,8 | 6,03 | 8,75 | 11,9 | 17,2 | 10,0 | 12,9 | 3,26 | 4,71 |

| 5390 060 160 | 60/160 | 27,1 | 34,4 | 23,3 | 30,1 | 6,96 | 9,82 | 15,1 | 21,5 | 13,2 | 17,2 | 3,97 | 5,61 |

| 5390 060 190 | 60/190 | 32,1 | 40,8 | 28,8 | 36,5 | 7,64 | 10,6 | 18,6 | 23,6 | 15,2 | 19,3 | 3,99 | 5,50 |

| 5390 070 125 | 70/125 | 18,7 | 25,8 | 11,9 | 18,8 | 5,99 | 8,96 | 9,57 | 14,4 | 7,13 | 11,2 | 3,60 | 5,38 |

| 5390 080 120 | 80/120 | 17,7 | 25,8 | 11,9 | 18,8 | 6,24 | 9,49 | 8,97 | 13,6 | 7,13 | 11,2 | 3,75 | 5,70 |

| 5390 080 140 | 80/140 | 23,6 | 30,1 | 17,3 | 25,8 | 7,16 | 10,7 | 11,9 | 17,2 | 10,0 | 12,9 | 3,53 | 5,23 |

| 5390 080 150 | 80/150 | 25,4 | 32,2 | 20,2 | 27,9 | 7,58 | 11,2 | 15,1 | 19,3 | 11,8 | 15,0 | 4,05 | 5,98 |

| 5390 080 180 | 80/180 | 30,4 | 38,7 | 27,1 | 34,4 | 8,66 | 12,5 | 16,9 | 21,5 | 13,5 | 17,2 | 4,22 | 6,05 |

| 5390 080 210 | 80/210 | 35,5 | 45,1 | 32,1 | 40,8 | 9,51 | 13,5 | 20,3 | 25,8 | 16,9 | 21,5 | 4,93 | 6,95 |

| 5390 100 140 | 100/140 | 23,6 | 30,1 | 17,3 | 25,8 | 7,65 | 11,7 | 11,9 | 17,2 | 10,0 | 12,9 | 3,78 | 5,77 |

| 5390 100 160 | 100/160 | 27,1 | 34,4 | 23,3 | 30,1 | 8,61 | 13,0 | 15,1 | 21,5 | 13,2 | 17,2 | 4,92 | 7,44 |

| 5390 100 170 | 100/170 | 28,8 | 36,5 | 25,4 | 32,2 | 9,05 | 13,6 | 16,9 | 21,5 | 13,5 | 17,2 | 4,78 | 7,15 |

| 5390 100 200 | 100/200 | 33,8 | 42,9 | 30,4 | 38,7 | 10,2 | 15,0 | 20,3 | 25,8 | 16,9 | 21,5 | 5,69 | 8,35 |

| 5390 120 160 | 120/160 | 27,1 | 34,4 | 23,3 | 30,1 | 9,04 | 13,9 | 15,1 | 21,5 | 13,2 | 17,2 | 5,16 | 7,97 |

| 5390 120 180 | 120/180 | 30,4 | 38,7 | 27,1 | 34,4 | 10,0 | 15,3 | 16,9 | 21,5 | 13,5 | 17,2 | 4,94 | 7,47 |

| 5390 120 190 | 120/190 | 32,1 | 40,8 | 28,8 | 36,5 | 10,5 | 15,9 | 18,6 | 23,6 | 15,2 | 19,3 | 5,51 | 8,32 |

| 5390 140 180 | 140/180 | 30,4 | 38,7 | 27,1 | 34,4 | 10,4 | 16,1 | 16,9 | 21,5 | 13,5 | 17,2 | 5,14 | 7,92 |

| Measured load capacity value: Fi,Rd = Fi,Rk × kmod/ƳM For combined effect of action, the following condition must be met: (Fy, Ed /Fy, Ed)^2+ (Fz, Ed/Fz, Rd)^2 ≤1 | |||||||||||||

| Notes: · Load-bearing capacities are valid for wood with a characteristic density Ƥk = 350 kg/m³. · Nail load-bearing capacities according to EN 1995-1-1. Pull-out capacity for load-bearing capacity class 3 according to DIN EN 1995-1-1/NA. · Würth ASSY joist hanger screws according to ETA-11/0190. · The force Fz acts in the centre of the secondary beam. The force Fy acts on the top edge of the joist hanger. In the case of a load application below the top edge of the joist hanger, the table values can be used on the safe side. At a different spacing of the force Fy, the load-bearing capacity can be determined according to ETA-08/0184. · Partial nailing: On the main support, the fasteners must be placed in the rows closest to the secondary beam. On the secondary beam, the fasteners must be evenly spaced over the height of the beam. The fasteners must always be arranged in the upper and lower holes. · The main support must be secured to prevent torsion. · The transverse tensile capacity of the main support must be investigated separately. · For one-sided connections on the main support, the offset moment must be taken into account. · The regulations of ETA-08/0184 must be observed. | |||||||||||||

| NOTE: These are guides for planning purposes. The values must be calculated for each project by authorised persons. | |||||||||||||

| CHARACTERISTIC LOAD-BEARING CAPACITIES IN KN OF WÜRTH COMBINATION JOIST HANGERS 1.5 MM (ETA-08/0184) WITH WÜRTH ANCHOR NAILS | |||||||||||||

| Art. no. | Format in mm | Complete nailing | Partial nailing | ||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | ||||||||

| 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | ||

| 5390 060 100 | 60/100 | 12,4 | 18,9 | 7,40 | 11,9 | 4,80 | 7,19 | 6,30 | 9,76 | 4,57 | 7,32 | 2,40 | 3,59 |

| 5390 060 120 | 60/120 | 17,7 | 25,8 | 11,9 | 18,8 | 5,66 | 8,29 | 8,97 | 13,6 | 7,13 | 11,2 | 3,40 | 4,98 |

| 5390 060 130 | 60/130 | 20,6 | 27,9 | 14,5 | 22,8 | 6,03 | 8,75 | 11,9 | 17,2 | 10,0 | 12,9 | 3,26 | 4,71 |

| 5390 060 160 | 60/160 | 27,1 | 34,4 | 23,3 | 30,1 | 6,96 | 9,82 | 15,1 | 21,5 | 13,2 | 17,2 | 3,97 | 5,61 |

| 5390 060 190 | 60/190 | 32,1 | 40,8 | 28,8 | 36,5 | 7,64 | 10,6 | 18,6 | 23,6 | 15,2 | 19,3 | 3,99 | 5,50 |

| 5390 070 125 | 70/125 | 18,7 | 25,8 | 11,9 | 18,8 | 5,99 | 8,96 | 9,57 | 14,4 | 7,13 | 11,2 | 3,60 | 5,38 |

| 5390 080 120 | 80/120 | 17,7 | 25,8 | 11,9 | 18,8 | 6,24 | 9,49 | 8,97 | 13,6 | 7,13 | 11,2 | 3,75 | 5,70 |

| 5390 080 140 | 80/140 | 23,6 | 30,1 | 17,3 | 25,8 | 7,16 | 10,7 | 11,9 | 17,2 | 10,0 | 12,9 | 3,53 | 5,23 |

| 5390 080 150 | 80/150 | 25,4 | 32,2 | 20,2 | 27,9 | 7,58 | 11,2 | 15,1 | 19,3 | 11,8 | 15,0 | 4,05 | 5,98 |

| 5390 080 180 | 80/180 | 30,4 | 38,7 | 27,1 | 34,4 | 8,66 | 12,5 | 16,9 | 21,5 | 13,5 | 17,2 | 4,22 | 6,05 |

| 5390 080 210 | 80/210 | 35,5 | 45,1 | 32,1 | 40,8 | 9,51 | 13,5 | 20,3 | 25,8 | 16,9 | 21,5 | 4,93 | 6,95 |

| 5390 100 140 | 100/140 | 23,6 | 30,1 | 17,3 | 25,8 | 7,65 | 11,7 | 11,9 | 17,2 | 10,0 | 12,9 | 3,78 | 5,77 |

| 5390 100 160 | 100/160 | 27,1 | 34,4 | 23,3 | 30,1 | 8,61 | 13,0 | 15,1 | 21,5 | 13,2 | 17,2 | 4,92 | 7,44 |

| 5390 100 170 | 100/170 | 28,8 | 36,5 | 25,4 | 32,2 | 9,05 | 13,6 | 16,9 | 21,5 | 13,5 | 17,2 | 4,78 | 7,15 |

| 5390 100 200 | 100/200 | 33,8 | 42,9 | 30,4 | 38,7 | 10,2 | 15,0 | 20,3 | 25,8 | 16,9 | 21,5 | 5,69 | 8,35 |

| 5390 120 160 | 120/160 | 27,1 | 34,4 | 23,3 | 30,1 | 9,04 | 13,9 | 15,1 | 21,5 | 13,2 | 17,2 | 5,16 | 7,97 |

| 5390 120 180 | 120/180 | 30,4 | 38,7 | 27,1 | 34,4 | 10,0 | 15,3 | 16,9 | 21,5 | 13,5 | 17,2 | 4,94 | 7,47 |

| 5390 120 190 | 120/190 | 32,1 | 40,8 | 28,8 | 36,5 | 10,5 | 15,9 | 18,6 | 23,6 | 15,2 | 19,3 | 5,51 | 8,32 |

| 5390 140 180 | 140/180 | 30,4 | 38,7 | 27,1 | 34,4 | 10,4 | 16,1 | 16,9 | 21,5 | 13,5 | 17,2 | 5,14 | 7,92 |

| Measured load capacity value: Fi,Rd = Fi,Rk × kmod/ƳM For combined effect of action, the following condition must be met: (Fy, Ed /Fy, Rd)^2+ (Fz, Ed /Fz, Rd)^2 ≤1 | |||||||||||||

| Notes: Load-bearing capacities are valid for wood with a characteristic density Ƥk = 350 kg/m³. Nail load-bearing capacities according to EN 1995-1-1. Pull-out capacity for load-bearing capacity class 3 according to DIN EN 1995-1-1/NA. Würth ASSY joist hanger screws according to ETA-11/0190. The force Fz acts in the centre of the secondary beam. The force Fy acts on the top edge of the joist hanger. In the case of a load application below the top edge of the joist hanger, the table values can be used on the safe side. At a different spacing of the force Fy, the load-bearing capacity can be determined according to ETA-08/0184. Partial nailing: On the main support, the fasteners must be placed in the rows closest to the secondary beam. On the secondary beam, the fasteners must be evenly spaced over the height of the beam. The fasteners must always be arranged in the upper and lower holes. The main support must be secured to prevent torsion. The transverse tensile capacity of the main support must be investigated separately. For one-sided connections on the main support, the offset moment must be taken into account. The regulations of ETA-08/0184 must be observed. | |||||||||||||

| Partial and complete nailing of Würth combination joist hangers 1.5 mm | ||||||||||||

| Parameters of Würth combination joist hanger 1.5 mm according to ETA-08/0184 | ||||||||||||

| Format w/H [mm] | Complete nailing | Partial nailing | ||||||||||

| nH | nJ | kH1 | kH2 | e1 | e2 | nH | nJ | kH1 | kH2 | e1 | e2 | |

| [pcs] | [pcs] | mm | mm | [pcs] | [pcs] | mm | mm | |||||

| 60/100 | 14 | 8 | 19,9 | 10,6 | 1252 | 708 | 8 | 4 | 9,68 | 6,61 | 620 | 426 |

| 60/120 | 18 | 10 | 29,7 | 17,6 | 1366 | 999 | 10 | 6 | 14,4 | 10,7 | 652 | 604 |

| 60/130 | 20 | 11 | 35,4 | 21,9 | 1394 | 1136 | 12 | 6 | 20,1 | 15,7 | 713 | 829 |

| 60/160 | 26 | 14 | 55,1 | 37,4 | 1667 | 1774 | 14 | 8 | 26,8 | 21,7 | 793 | 1110 |

| 60/190 | 32 | 17 | 79 | 57,2 | 1938 | 2546 | 18 | 9 | 43 | 36,6 | 1004 | 1883 |

| 70/125 | 18 | 10 | 32,3 | 17,6 | 1581 | 1068 | 10 | 6 | 15,8 | 10,7 | 767 | 634 |

| 80/120 | 18 | 10 | 29,7 | 17,6 | 1817 | 1140 | 10 | 6 | 14,4 | 10,7 | 894 | 669 |

| 80/140 | 22 | 12 | 41,5 | 26,6 | 1954 | 1505 | 12 | 6 | 20,1 | 15,7 | 943 | 887 |

| 80/150 | 24 | 13 | 48 | 31,7 | 1995 | 1679 | 14 | 7 | 26,8 | 21,7 | 1017 | 1150 |

| 80/180 | 30 | 16 | 70,6 | 50,1 | 2307 | 2434 | 16 | 8 | 34,4 | 28,7 | 1109 | 1468 |

| 80/210 | 36 | 19 | 97,4 | 72,7 | 2616 | 3319 | 20 | 10 | 52,2 | 45,5 | 1344 | 2295 |

| 100/140 | 22 | 12 | 41,5 | 26,6 | 2487 | 1676 | 12 | 6 | 20,1 | 15,7 | 1223 | 965 |

| 100/160 | 26 | 14 | 55,1 | 37,4 | 2649 | 2116 | 14 | 8 | 26,8 | 21,7 | 1288 | 1223 |

| 100/170 | 28 | 15 | 62,6 | 43,5 | 2704 | 2328 | 16 | 8 | 34,4 | 28,7 | 1374 | 1526 |

| 100/200 | 34 | 18 | 88 | 64,7 | 3054 | 3201 | 18 | 10 | 43,3 | 36,6 | 1479 | 1881 |

| 120/160 | 26 | 14 | 55,1 | 37,4 | 3262 | 2316 | 14 | 8 | 26,8 | 21,7 | 1607 | 1314 |

| 120/180 | 30 | 16 | 70, | 50,1 | 3451 | 2833 | 16 | 8 | 34,4 | 28,7 | 1686 | 1612 |

| 120/190 | 32 | 17 | 79 | 57,2 | 3518 | 3084 | 18 | 9 | 43 | 36,6 | 1785 | 1955 |

| 140/180 | 30 | 16 | 70,6 | 50,1 | 4145 | 3063 | 16 | 8 | 34,4 | 28,7 | 2043 | 1717 |

| Format in mm | Complete nailing | Partial nailing | ||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | |||||||

| 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | |

| 60/100 | 21,5 | 22,9 | 17,2 | 18,3 | 8,96 | 9,85 | 12,9 | 13,8 | 8,60 | 9,17 | 4,48 | 4,93 |

| 60/120 | 25,8 | 27,5 | 21,5 | 22,9 | 9,93 | 10,9 | 17,2 | 18,3 | 12,9 | 13,8 | 5,96 | 6,51 |

| 60/130 | 27,9 | 29,8 | 23,6 | 25,2 | 10,3 | 11,2 | 17,2 | 18,3 | 12,9 | 13,8 | 5,51 | 6,00 |

| 60/160 | 34,4 | 36,7 | 30,1 | 32,1 | 11,1 | 12,0 | 21,5 | 22,9 | 17,2 | 18,3 | 6,35 | 6,87 |

| 60/190 | 40,8 | 43,6 | 36,5 | 39,0 | 11,6 | 12,5 | 23,6 | 25,2 | 19,3 | 20,6 | 6,01 | 6,48 |

| 70/125 | 25,8 | 27,5 | 21,5 | 22,9 | 11,1 | 12,3 | 17,2 | 18,3 | 12,9 | 13,8 | 6,69 | 7,36 |

| 80/120 | 25,8 | 27,5 | 21,5 | 22,9 | 12,2 | 13,5 | 17,2 | 18,3 | 12,9 | 13,8 | 7,33 | 8,12 |

| 80/140 | 30,1 | 32,1 | 25,8 | 27,5 | 13,3 | 14,6 | 17,2 | 18,3 | 12,9 | 13,8 | 6,42 | 7,04 |

| 80/150 | 32,2 | 34,4 | 27,9 | 29,8 | 13,7 | 15,0 | 19,3 | 20,6 | 15,0 | 16,0 | 7,27 | 7,96 |

| 80/180 | 38,7 | 41,3 | 34,4 | 36,7 | 14,6 | 15,9 | 21,5 | 22,9 | 17,2 | 18,3 | 7,00 | 7,60 |

| 80/210 | 45,1 | 48,1 | 40,8 | 43,6 | 15,3 | 16,5 | 25,8 | 27,5 | 21,5 | 22,9 | 7,84 | 8,48 |

| 100/140 | 30,1 | 32,1 | 25,8 | 27,5 | 15,4 | 17,1 | 17,2 | 18,3 | 12,9 | 13,8 | 7,50 | 8,31 |

| 100/160 | 34,4 | 36,7 | 30,1 | 32,1 | 16,5 | 18,2 | 21,5 | 22,9 | 17,2 | 18,3 | 9,45 | 10,4 |

| 100/170 | 36,5 | 39,0 | 32,2 | 34,4 | 17,0 | 18,7 | 21,5 | 22,9 | 17,2 | 18,3 | 8,87 | 9,75 |

| 100/200 | 43,0 | 45,8 | 38,7 | 41,3 | 18,1 | 19,7 | 25,8 | 27,5 | 21,5 | 22,9 | 10,0 | 11,0 |

| 120/160 | 34,4 | 36,7 | 30,1 | 32,1 | 18,6 | 20,7 | 21,5 | 22,9 | 17,2 | 18,3 | 10,6 | 11,8 |

| 120/180 | 38,7 | 41,3 | 34,4 | 36,7 | 19,7 | 21,9 | 21,5 | 22,9 | 17,2 | 18,3 | 9,51 | 10,5 |

| 120/190 | 40,8 | 43,6 | 36,5 | 39,0 | 20,2 | 22,3 | 23,6 | 25,2 | 19,3 | 20,6 | 10,5 | 11,6 |

| 140/180 | 38,7 | 41,3 | 34,4 | 36,7 | 21,7 | 24,2 | 21,5 | 22,9 | 17,2 | 18,3 | 10,5 | 11,7 |

| Measured load capacity value: Fi,Rd = Fi,Rk × kmod/gM For combined effect of action, the following condition must be met: Notes: Load-bearing capacities are valid for wood with a characteristic density rk = 350 kg/m³. Nail load-bearing capacities according to EN 1995-1-1. Pull-out capacity for load-bearing capacity class 3 according to DIN EN 1995-1-1/NA. Würth ASSY joist hanger screws according to ETA-11/0190. The force Fz acts in the centre of the secondary beam. The force Fy acts on the top edge of the joist hanger. In the case of a load application below the top edge of the joist hanger, the table values can be used on the safe side. At a different spacing of the force Fy, the load-bearing capacity can be determined according to ETA-08/0184. Partial nailing: On the main support, the fasteners must be placed in the rows closest to the secondary beam. On the secondary beam, the fasteners must be evenly spaced over the height of the beam. The fasteners must always be arranged in the upper and lower holes. The main support must be secured to prevent torsion. The transverse tensile capacity of the main support must be investigated separately. For one-sided connections on the main support, the offset moment must be taken into account. The regulations of ETA-08/0184 must be observed. | ||||||||||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!