Conical countersink assortment 6 pieces. Green ring HSCO 90° DIN 335 C

Con. c/sink HSCo green ring DIN 335C 6 pcs Syska

CNTSNK-CONI-SORT-GRN-HSCO-90°-(6,3-20,5)

Art.-no. 0694019006

EAN 4065233070950

Register now and access more than 125,000 products

Burr- and chatter-free countersinking and deburring

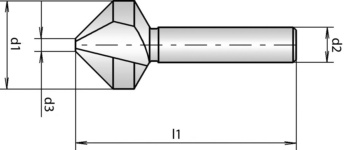

Precision conical countersink with 3 cutting edges, precision-ground

Optimised spiral flute geometry

Excellent chip formation and removal

Suitable for the ORSY® system, compact and practical system cassette with useful details, such as stackability, optimised joint and simple opening

Datasheets(X)

| |

Number of pieces in assortment/set | 6 PCS |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Special alloy |

Quality | ZEBRA-Premium |

Standards | DIN 335 |

Form | C |

Cutting material | HSCo |

Countersink angle | 90 Degree |

Surface | Uncoated |

Number of cutting edges | 3 PCS |

Shank style | Cylindrical |

Service life (points system) | 2 of 4 points |

Countersinking speed (point system) | 2 of 4 points |

Countersinking quality (point system) | 2 of 4 points |

Versatility (points system) | 2 of 4 points |

Countersinking behaviour (point system) | 2 of 4 points |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, sulphurated, Stainless steels, austenitic, Stainless steels, martensitic, Titanium, Titanium alloys, Special alloys, Spring steels |

| Assignment of conical countersink to screw standards | ||

| Conical countersink nominal diameter d1 | For countersunk head screws | For countersunk head screws |

| DIN EN ISO 10642 (formerly DIN 7991) | DIN EN ISO 2009, 2010, 7046, 7047 (formerly DIN 963,964,965,966) | |

| 6.3 mm | M3 | M3 |

| 8.3 mm | M4 | - |

| 10.4 mm | M5 | M4, M5 |

| 12.4 mm | M6 | M6 |

| 16.5 mm | M8 | M8 |

| 20.5 mm | - | M10 |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For dia. 16.5-31 | ||||||

| Material designation | Tensile strength | vc | f | |||

| Dia. 16.5 | Dia. 20.5 | Dia. 25 | Dia. 31 | |||

| Steels | ||||||

| General structural steels | ≤ 500 N/mm² | 35 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 1,000 N/mm² | 33 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Unalloyed quenched and tempered steels | ≤ 700 N/mm² | 35 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 850 N/mm² | 33 | 0,170 | 0,180 | 0,210 | 0,240 | |

| ≤ 1,000 N/mm² | 22 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Alloyed quenched and tempered steels | ≤ 1,000 N/mm² | 17 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 1,400 N/mm² | 13 | 0,110 | 0,130 | 0,150 | 0,170 | |

| Nitriding steels | ≤ 1,000 N/mm² | 17 | 0,110 | 0,130 | 0,150 | 0,170 |

| ≤ 1,400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,120 | |

| Tool steels | ≤ 850 N/mm² | 19 | 0,110 | 0,130 | 0,150 | 0,170 |

| ≤ 1,400 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,120 | |

| High-speed steels | ≤ 1,400 N/mm² | 17 | 0,070 | 0,080 | 0,150 | 0,120 |

| High-grade steels | ||||||

| Sulphurated stainless steels | ≤ 900 N/mm² | 18 | 0,110 | 0,130 | 0,150 | 0,170 |

| Austenitic stainless steels | ≤ 1,100 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,120 |

| Martensitic stainless steels | ≤ 1,200 N/mm² | 15 | 0,070 | 0,080 | 0,090 | 0,120 |

| Titanium and titanium alloys | ≤ 850 N/mm² | 17 | 0,110 | 0,130 | 0,150 | 0,170 |

| ≤ 1,400 N/mm² | 11 | 0,070 | 0,080 | 0,090 | 0,120 | |

| Special alloys | ≤ 1,600 N/mm² | 9 | 0,110 | 0,130 | 0,150 | 0,170 |

| Cast metals | ||||||

| Cast iron | ≤ 240 HB | 28 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 350 HB | 18 | 0,170 | 0,180 | 0,210 | 0,240 | |

| Spheroidal graphite and malleable iron | ≤ 240 HB | 24 | 0,170 | 0,180 | 0,210 | 0,240 |

| ≤ 350 HB | 22 | 0,170 | 0,180 | 0,210 | 0,240 | |

| Chilled cast iron | ≤ 350 HB | 9 | 0,070 | 0,080 | 0,090 | 0,120 |

| Hard materials | ||||||

| Spring steels | ≤ 350 HB | 11 | 0,070 | 0,080 | 0,090 | 0,120 |

| Cutting values | ||||||

| For dia. 6.3-12.4 | ||||||

| Material designation | Tensile strength | vc | f | |||

| Dia. 6.3 | Dia. 8.3 | Dia. 10.4 | Dia. 12.4 | |||

| Steels | ||||||

| General structural steels | ≤ 500 N/mm² | 35 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 1,000 N/mm² | 33 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Unalloyed quenched and tempered steels | ≤ 700 N/mm² | 35 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 850 N/mm² | 33 | 0,120 | 0,130 | 0,140 | 0,150 | |

| ≤ 1,000 N/mm² | 22 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Alloyed quenched and tempered steels | ≤ 1,000 N/mm² | 17 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 1,400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Nitriding steels | ≤ 1,000 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1,400 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 | |

| Tool steels | ≤ 850 N/mm² | 19 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1,400 N/mm² | 17 | 0,040 | 0,050 | 0,060 | 0,060 | |

| High-speed steels | ≤ 1,400 N/mm² | 17 | 0,040 | 0,050 | 0,060 | 0,060 |

| High-grade steels | ||||||

| Sulphurated stainless steels | ≤ 900 N/mm² | 18 | 0,068 | 0,081 | 0,090 | 0,100 |

| Austenitic stainless steels | ≤ 1,100 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 |

| Martensitic stainless steels | ≤ 1,200 N/mm² | 15 | 0,040 | 0,050 | 0,060 | 0,060 |

| Titanium and titanium alloys | ≤ 850 N/mm² | 17 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1,400 N/mm² | 11 | 0,040 | 0,050 | 0,060 | 0,060 | |

| Special alloys | ≤ 1,600 N/mm² | 9 | 0,070 | 0,080 | 0,090 | 0,100 |

| Cast metals | ||||||

| Cast iron | ≤ 240 HB | 28 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 18 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Spheroidal graphite and malleable iron | ≤ 240 HB | 24 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 22 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Chilled cast iron | ≤ 350 HB | 9 | 0,040 | 0,050 | 0,060 | 0,060 |

| Hard materials | ||||||

| Spring steels | ≤ 350 HB | 11 | 0,040 | 0,050 | 0,060 | 0,060 |

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!