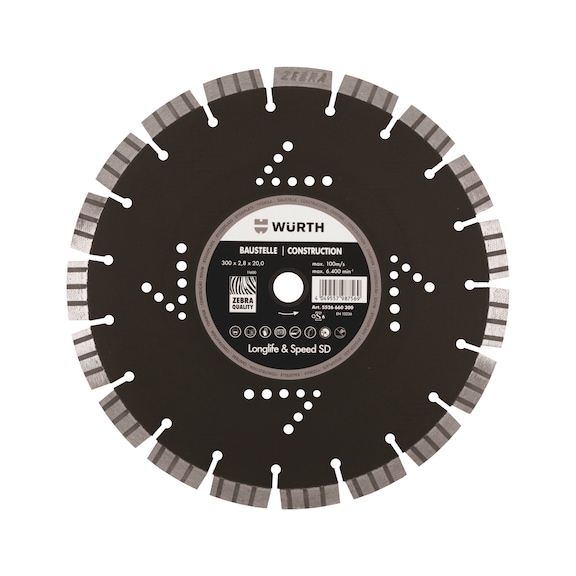

Diamond cutting disc, long life & speed SD, construction site

Diamond cutting disc LS SD constr. hand/joint cut.

CUTDISC-DIA-LS-SD-CNST-BR20,0-D300MM

Art.-no. 5526660300

EAN 4049557987569

Register now and access more than 125,000 products

Patented SD technology (structured diamonds)

For up to 70% more cutting performance and service life compared to the competition. The special even orientation of the diamonds ensures that there are always sufficient diamonds on the surface, resulting in a clean, fast cut. In addition, the even orientation of the diamonds ensures permanent optimum utilisation of the entire cutting width.

Less resistance in the material

The segments, which are approx. 10% narrower than in competitor products, prevent unnecessary friction losses.

This also results in a longer service life due to 40% higher segments

Instead of the usual 10 mm, up to 14 mm segment height with effectively 40% more cutting diamonds.

Optimised dust removal and cooling

The fan segments feed in cooling air and transport the dust out of the cut. Special cooling openings with an "arrow arrangement" serve as additional cooling and as a captive running direction indicator.

Smoother running and more pleasant working conditions

PTFE-filled slits known as "Silent Holes" reduce uncontrolled vibrations and unpleasant running noise.

- Diamond cutting discs become blunt at excessively high rotation speeds and wear too rapidly at insufficient peripheral surface speeds

- If ease of cutting is lost (indicated by heavy sparking), resharpen the disc in abrasive material, e.g. sandstone, with several cuts

- Cut larger workpiece cross-sections into several sections (swing cut)

- Work without applying pressure – the weight of the machine is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs – risk of injury!

- Despite the level of safety offered by the tool, always wear safety glasses and clothing while working

- Observe the information on the label (max. rotation speed), the restrictions of use and the safety instructions

- The direction arrow on the disc must match the machine's direction of rotation

- Must not be used for lateral grinding

- Use the appropriate protective hood

- Clamping must be performed only by a trained specialist (do not use force, use clean clamping flanges of the same size, perform a test run)

- If grinding tools are clamped or used incorrectly or are damaged, they represent a danger and may cause serious injury

Datasheets(X)

For dry and wet cutting

Versatility (points system) | 3 of 4 points |

Service life (points system) | 4 of 4 points |

Cutting speed (point system) | 4 of 4 points |

Cut quality (point system) | 3 of 4 points |

Diameter (Ø) | 300 mm |

Bore hole | 20 mm |

Segment height | 14 mm |

Segment thickness | 2.4 mm |

Number of segments | 19 PCS |

Segment connection | Laser |

Max. rotation speed | 6400 rpm |

Max. circumferential speed | 100 m/s |