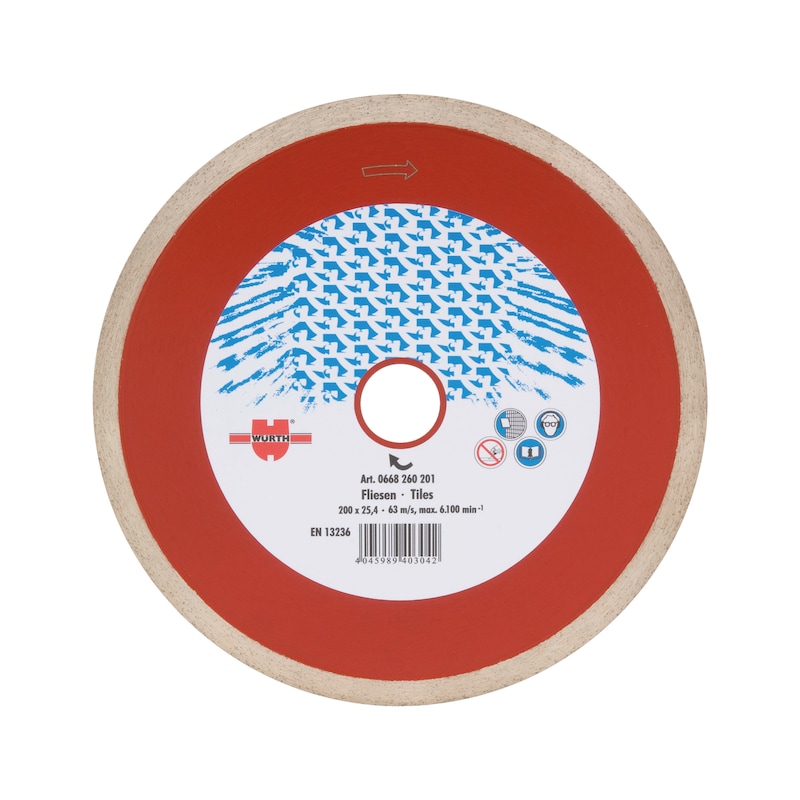

Diamond wet-cutting disc, tile For diamond tile cutting machines

Diamond wet cutting disc tile

CUTDISC-DIA-TILES-WETCUT-BR25,4-D200MM

Register now and access more than 125,000 products

- Diamond cutting discs become dull at excessively high speeds and wear too rapidly at insufficient circumferential speeds

- If the ease of cutting decreases (indicated by heavy sparking), resharpen the disc in abrasive material, e.g. sandstone, with several cuts

- Separate larger workpiece cross-sections in several sections (swing cut)

- Work without pressure — the weight of the machine is sufficient. Increased pressure causes increased wear.

- Diamond cutting discs are designed for straight cutting. Cutting curves deforms the blade and results in core cracks and segment tear-offs — risk of injury!

- Although the tool is safe, always wear protective goggles and clothing while working

- Observe the information on the label (max. speed!), the restrictions of use and the safety instructions

- The direction arrow on the disc must match the machine's direction of rotation

- Must not be used for lateral grinding

- Use the appropriate protective hood

- Clamping must be performed only by a trained specialist (do not use force, use clean clamping flanges of the same size, perform a test run)

- If grinding tools are clamped or used incorrectly or are damaged, they represent a danger and may cause serious injury

Diameter (Ø) | 200 mm |

Drill hole | 25.4 mm |

Segment height | 10 mm |

Segment thickness | 2.2 mm |

Number of segments | 1 PCS |

Segment connection | Soldered |

Max. circumferential speed | 63 m/s |

Datasheets (0)

Certificates/ Documents (0)