Drilling screw, hexagon head with collar and slot pias®

pias steel zinc plated hexagon head with flange

SCR-DBIT-HEX-FLG-SL-WS8-(A3K)-4,8X13

ZEBRA PIAS

Register now and access more than 125,000 products

Drilling, threading, screwing-in — all in one work step

Therefore considerably reduced time and effort

Exact drilling diameter for each screw connection

This minimises the thread tolerance thereby always ensuring an optimum connection

Prevents installation errors

- Drilling screws must be processed with a suitable drill driver (e.g. cordless drill driver with depth stop)

- The use of impact screwdrivers is not permitted

- Drilling screws must be attached perpendicular to the surface of the component

Galvanized drilling screws may only be used where dampness is not to be expected. For fasteners with a construction approval, the approval, and in particular Part 2 "Special regulations", must always be observed.

Datasheets(X)

CAD data (available after login)

- Especially suited for use in ventilation systems and air-conditioning technology

- Hexagon head with slot for quick loosening in case of repairs

| |

Standards | CS |

Material | Steel |

Surface | Zinc plated |

RoHS-compliant | Yes |

Head type | Hexagon head |

Drive type | Slot/hexagon |

Thread type | Self-tapping screw thread |

Shape of tip | Drilling tip |

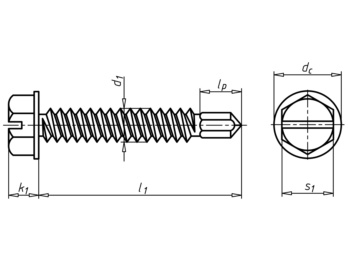

Nominal diameter (d1) | 4.8 mm |

Length (l1) | 13 mm |

Flange diameter (dk) | 10.5 mm |

Head height (k1) | 4.45 mm |

Drill tip length (lp) | 4.5 mm |

External drive (s1) | WS8 |

Max. material thickness to be drilled through (metal) | 4.0 mm |

Min. recommended substructure thickness | 1.5 mm |

Min./max. recommended installation speed (idling) | 1200-1800 rpm |