Drop-in anchor W-ED/S-BND

Wedge anchor W-ED/S-BND steel zinc ptd. w. collar

ANC-(W-ED/S)-FLG-(A2K)-M12X50

Art.-no. 090404012

EAN 4049557024653

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Female thread anchor with collar and metric thread for economical anchoring in concrete, zinc plated steel

- Small drill hole depth

- High load-bearing capacities

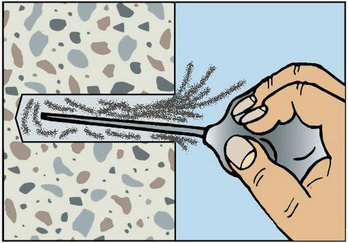

- Visual setting check and hand protection when installing with the marking/spreading tool

- Mechanical setting tool makes installation quicker and easier

- Immediate load-bearing capacity — no waiting

- Attached part can easily be removed at any time

- W-ED/S has collar enabling anchor to be installed flush with the surface and preventing it slipping further into the drill hole (safer installation)

- The attached part can be anchored with a fastening screw or a threaded rod

- No installation torque required

Proof of Performance

- ETA-02/0044 for individual fixing point, option 7, uncracked concrete

- ETA-05/0120 for anchors in a redundant non-structural system, uncracked and cracked concrete

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 4102-2:1977-09 (UTTC - uniform temperature time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-05/0120)

Notice

Drive-in anchor W-ED/A4 see [13.2]

Application area

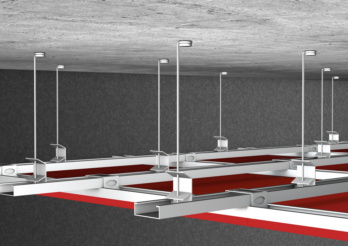

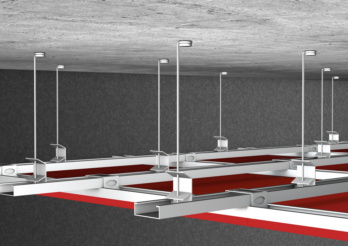

Suspended ceilings

Suspended ceilings

Suspended ceilings

Suspended ceilings

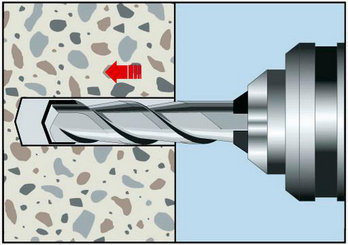

Drill the hole

Clean the drill hole

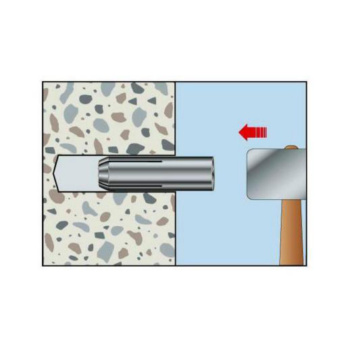

Knock in anchor until flush

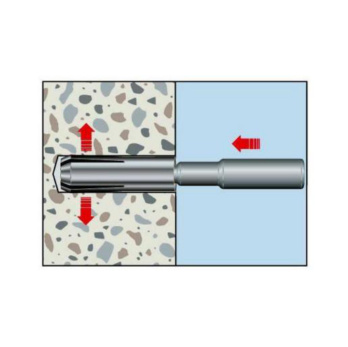

Anchor with expander tool

Fit component, apply torque

- ETA-02/0044 for individual fixing point, option 7, uncracked concrete

- ETA-05/0120 for anchors in a redundant non-structural system, uncracked and cracked concrete

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 4102-2:1977-09 (UTTC - uniform temperature time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-05/0120)

Product information

Datasheets(X)

CAD data (available after login)

Application area

- Individual fixing point: Normal weight concrete C20/25 to C50/60 (uncracked concrete)

- Anchors in a redundant non-structural system: Anchorage of non-load-bearing systems (cracked and uncracked concrete)

- Suitable for fastening threaded rods, metal structures, metal profiles, lattices, cable conduits, pipes, mounting rails etc.

- For use in concrete < C20/25 and pressure-resistant natural stone (without approval)

- W-ED/S, W-ED/S-BND and W-ED M5 may only be used in dry indoor conditions

Anchor diameter | 12 mm |

Anchor length (L H) | 50 mm |

Min./max. required screw-in depth | 13-18 mm |

Material | Steel |

Surface | Zinc plated |

Nominal drill-bit diameter (d 0) | 15 mm |

Drill hole depth (h 0) | 50 mm |

Effective anchoring depth (h ef) | 50 mm |

Torque during anchoring (T inst) | 35 Nm |

Through-hole in the component to be connected (d f) | 14 mm |

| Installation parameters in hollow-core prestressed concrete ceilings | |||||

| Anchor size [mm] | M6x25 | M8x25 | M10x25 | M12x25 | |

| Mirror thickness | db ≥ [mm] | 35 (30)2) | |||

| Minimum axis distance | smin [mm] | 200 | |||

| Minimum edge distance | cmin [mm] | 150 | |||

| Nominal drill ∅ | d0 [mm] | 8 | 10 | 12 | 15 |

| Drill cutting ∅ | dcut ≤ [mm] | 8,45 | 10,45 | 12,5 | 15,5 |

| Drill hole depth | h0 = [mm] | 25 | 25 | 25 | 25 |

| Through hole in the component being connected | df ≤ [mm] | 7 | 9 | 12 | 14 |

| Thread depth (max. length of thread engagement) | Lth [mm] | 12 | 12 | 12 | 12 |

| Minimum length of thread engagement | Lsdmin ≤ [mm] | 6 | 8 | 10 | 12 |

| Torque while installing anchor | Tinst ≤ [Nm] | 4 | 8 | 15 | 35 |

| Spacing between cavity axes | lc ≥ [mm] | 100 | |||

| Spacing between tensioning strands | lp ≥ [mm] | 100 | |||

| Spacing between tensioning strands and drill hole | ap ≥ [mm] | 50 | |||

| Performance data in hollow-core prestressed concrete ceilings – anchors in a redundant non-structural system (screw 4.6-8.8) | |||||

| Mirror thickness | db ≥ [mm] | 35 (30)2) | |||

| Anchor size [mm] | M6x25 | M8x25 | M10x25 | M12x25 | |

| Anchors in a redundant non-structural system in hollow-core prestressed concrete ceilings | Fadm [kN] | 1.79) | 1.99) | 2.19) | 2.19) |

| Admissible bending moment7) | Madm [Nm] | 3,3 | 8,1 | 15,8 | 27,8 |

| Performance data in cracked and uncracked concrete - anchors in a redundant non-structural system (screw 4.6-8.8) | ||||||||||||

| Anchor size [mm] | M6x25 | M6x30 | M8x25 | M8x30 | M8x40 | M10x25 | M10x30 | M10x40 | M12x25 | M12x50 | M16x65 | |

| Anchors in a redundant non-structural system in concrete10) | Fadm [kN] = C12/15 - C16/204) | 1,2 | - | 1,2 | - | - | 1.79) | - | - | 1.79) | - | - |

| Fadm [kN] = C20/25 - C50/604) | 1.79) | 1,2 | 1.99) | 1.79) | 2.09) | 2.19) | 2.09) | 2.09) | 2.19) | 2.49) | 6.39) | |

| Admissible bending moment7) | Madm [Nm] | 3,3 | 8,1 | 15,8 | 27,8 | 71,0 | ||||||

| Admissible load when exposed to fire10) | R30 [kN] | 0,4 | 0,8 | 0,6 | 0,9 | 1,5 | 0,6 | 0,9 | 1,5 | 0,6 | 1,5 | 4 |

| R60 [kN] | 0,4 | 0,8 | 0,6 | 0,9 | 1,5 | 0,6 | 0,9 | 1,5 | 0,6 | 1,5 | 4 | |

| R90 [kN] | 0,3 | 0,4 | 0,6 | 0,9 | 0,9 | 0,6 | 0,9 | 1,5 | 0,6 | 1,5 | 3,7 | |

| R120 [kN] | 0,3 | 0,3 | 0,5 | 0,5 | 0,5 | 0,5 | 0,7 | 1,0 | 0,5 | 1,2 | 2,4 | |

| Performance data in uncracked concrete - individual fixing point (screw 4.6-8.8)

| |||||||||||

| Anchor size [mm] | M5x251)6) | M6x306) | M8x306) | M8x40 | M10x306) | M10x40 | M12x50 | M16x65 | M20x80 | ||

| Admissible centric tension load3) on an individual anchor without the influence of the edge distance | Compressive zone (uncracked concrete C20/254), s ≥ 3 hef, c ≥ cmin) | Nadm [kN] = C20/244) | Frec 1.4 | 3,3 | 3,3 | 3,6 | 3,3 | 5,1 | 7,1 | 10,5 | 14,3 |

| Admissible shear load3) on an individual anchor without the influence of the edge distance | Compressive zone (uncracked concrete C20/254), s ≥ 3 hef, c ≥ cmin) | Vadm [kN] = C20/244)5) | Frec 1.5 | 2,1 | 3,9 | 3,9 | 4,0 | 4,1 | 9,0 | 16,8 | 26,2 |

| Admissible bending moment7) | Madm [Nm] | - | 3,3 | 8,1 | 15,8 | 27,8 | 71,0 | 138,6 | |||

| Fire resistance8) according to UTTC (uniform temperature time curve) | F30 [kN] | - | 1,7 | 1,7 | 3,0 | - | 4,7 | 6,9 | 12,5 | 18,0 | |

| F60 [kN] | - | 0,7 | 0,7 | 1,5 | - | 2,4 | 3,5 | 5,6 | 8,5 | ||

| F90 [kN] | - | 0,4 | 0,4 | 0,8 | - | 1,3 | 1,8 | 3,5 | 5,5 | ||

| F120 [kN] | - | 0,3 | 0,3 | 0,6 | - | 1,0 | 1,4 | 2,5 | 4,4 | ||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!