EU HSCo 60° countersink DIN 334C

Conical countersink EU HSCo 60° DIN 334

CNTSNK-CONI-EU-HSCO-60DGR-DIN334C-D6,3MM

Art.-no. 5443121006

EAN 4062856443895

Register now and access more than 125,000 products

Extremely uneven pitch

- Maximum surface quality: exact, round, chatter-free countersinks

- Faster processing thanks to higher cutting speeds

- Greatly reduced tool wear

- Maximum smoothness in all materials

- Much less feed force required

For universal use

Processing of almost all materials possible thanks to special tip geometry and HSCo cutting material.

Datasheets(X)

| |

Product code | 2270 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Special alloy, Hard and tough material, Non-ferrous metal, Plastic |

Quality | ZEBRA-Premium |

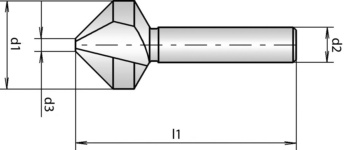

Spot-facer diameter (d1) | 6.3 mm |

Shank diameter (d2) | 5 mm |

Tip diameter (d3) | 4.0 mm |

Length (l1) | 45 mm |

Number of cutting edges (Z) | 3 PCS |

Standards | DIN 334 |

Form | C |

Cutting material | HSCo |

Countersink angle | 60 Degree |

Surface | Uncoated |

Shank style | Cylindrical |

Service life (points system) | 3 of 4 points |

Countersinking speed (point system) | 4 of 4 points |

Countersinking quality (point system) | 4 of 4 points |

Versatility (points system) | 4 of 4 points |

Countersinking behaviour (point system) | 3 of 4 points |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, sulphurated, Stainless steels, austenitic, Stainless steels, martensitic, Titanium, Titanium alloys, Special alloys, Hardox, Spring steels, Aluminium, Aluminium alloys, Aluminium casting alloys (<10% silicon), Aluminium casting alloys (>10% silicon), Magnesium alloys, Copper, low-alloyed, Brass, short-chipping, Brass, long-chipping, Bronze, short-chipping, Bronze, long-chipping, Plastics, thermoset, Plastics, thermoplastic |

| Cutting values for HSS countersinks, coated | ||||||

| For dia. 6.3–12.4 | ||||||

| Material designation | Tensile strength | vc | f | |||

| Dia. 6.3 | Dia. 8.3 | Dia. 10.4 | Dia. 12.4 | |||

| General structural steels | ≤ 500 N/mm² | 45 | 0,120 | 0,130 | 0,135 | 0,150 |

| ≤ 1000 N/mm² | 42 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Unalloyed heat-treated steels | ≤ 700 N/mm² | 42 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 850 N/mm² | 42 | 0,120 | 0,130 | 0,135 | 0,150 | |

| ≤ 1000 N/mm² | 34 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Alloyed heat-treated steels | ≤ 1000 N/mm² | 34 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 1400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | 0,100 | |

| Nitriding steels | ≤ 1000 N/mm² | 34 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1400 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 | |

| Tool steels | ≤ 850 N/mm² | 34 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1400 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 | |

| High-speed steels | ≤ 1400 N/mm² | 13 | 0,040 | 0,050 | 0,060 | 0,060 |

| Cast iron | ≤ 240 HB | 21 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 18 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Spheroidal-graphite and malleable iron | ≤ 240 HB | 18 | 0,120 | 0,130 | 0,140 | 0,150 |

| ≤ 350 HB | 18 | 0,120 | 0,130 | 0,140 | 0,150 | |

| Chilled cast iron | ≤ 350 HB | 18 | 0,040 | 0,050 | 0,060 | 0,060 |

| Stainless steels, sulphurated | ≤ 900 N/mm² | 9 | 0,068 | 0,081 | 0,090 | 0,100 |

| Stainless steels, austenitic | ≤ 1100 N/mm² | 9 | 0,040 | 0,050 | 0,060 | 0,060 |

| Stainless steels, martensitic | ≤ 1200 N/mm² | 9 | 0,040 | 0,050 | 0,060 | 0,060 |

| Titanium and titanium alloys | ≤ 850 N/mm² | 9 | 0,070 | 0,080 | 0,090 | 0,100 |

| ≤ 1400 N/mm² | 9 | 0,040 | 0,050 | 0,060 | 0,060 | |

| Special alloys | ≤ 1600 N/mm² | 7 | 0,070 | 0,080 | 0,090 | 0,100 |

| Hardox | Hardox 400–500, XAR 320, XAR 400 | 4 | 0,070 | 0,080 | 0,080 | 0,090 |

| Spring steels | ≤ 350 HB | 9 | 0,040 | 0,050 | 0,060 | 0,060 |

| Aluminium and aluminium alloys | ≤ 400 N/mm² | 77 | 0,150 | 0,162 | 0,170 | 0,190 |

| Wrought aluminium alloys | ≤ 650 N/mm² | 55 | 0,150 | 0,162 | 0,170 | 0,190 |

| Cast aluminium alloys ≤ 10% Si | ≤ 600 N/mm² | 33 | 0,120 | 0,130 | 0,140 | 0,150 |

| Cast aluminium alloys > 10% Si | ≤ 600 N/mm² | 22 | 0,120 | 0,130 | 0,140 | 0,150 |

| Magnesium alloys | ≤ 400 N/mm² | 77 | 0,150 | 0,160 | 0,170 | 0,190 |

| Copper, low-alloyed | ≤ 500 N/mm² | 33 | 0,150 | 0,160 | 0,170 | 0,190 |

| Brass, short-chipping | ≤ 600 N/mm² | 72 | 0,150 | 0,160 | 0,170 | 0,190 |

| Brass, long-chipping | ≤ 600 N/mm² | 44 | 0,150 | 0,160 | 0,170 | 0,190 |

| Bronze, short-chipping | ≤ 600 N/mm² | 72 | 0,150 | 0,160 | 0,170 | 0,190 |

| ≤ 850 N/mm² | 72 | 0,150 | 0,160 | 0,170 | 0,190 | |

| Bronze, long-chipping | ≤ 850 N/mm² | 44 | 0,150 | 0,160 | 0,170 | 0,190 |

| ≤ 1000 N/mm² | 44 | 0,150 | 0,160 | 0,170 | 0,190 | |

| Plastics | ≤ 150 N/mm² | 33 | 0,150 | 0,160 | 0,170 | 0,190 |

| Legend | |

| vc = cutting speed [m/min] | |

| f = feed (mm/r) | |

| The suggested cutting values are reference values and must be adapted to the respective conditions. | |

| Cutting values for HSS countersinks, coated | |||||

| For dia. 16.5–25 | |||||

| Material designation | Tensile strength | vc | f | ||

| Dia. 16.5 | Dia. 20.5 | Dia. 25 | |||

| General structural steels | ≤ 500 N/mm² | 45 | 0,170 | 0,180 | 0,210 |

| ≤ 1000 N/mm² | 42 | 0,110 | 0,130 | 0,150 | |

| Unalloyed heat-treated steels | ≤ 700 N/mm² | 42 | 0,170 | 0,180 | 0,210 |

| ≤ 850 N/mm² | 42 | 0,170 | 0,180 | 0,210 | |

| ≤ 1000 N/mm² | 34 | 0,110 | 0,130 | 0,150 | |

| Alloyed heat-treated steels | ≤ 1000 N/mm² | 34 | 0,170 | 0,180 | 0,210 |

| ≤ 1400 N/mm² | 13 | 0,110 | 0,130 | 0,150 | |

| Nitriding steels | ≤ 1000 N/mm² | 34 | 0,110 | 0,130 | 0,150 |

| ≤ 1400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | |

| Tool steels | ≤ 850 N/mm² | 34 | 0,110 | 0,130 | 0,150 |

| ≤ 1400 N/mm² | 13 | 0,070 | 0,080 | 0,090 | |

| High-speed steels | ≤ 1400 N/mm² | 13 | 0,070 | 0,080 | 0,090 |

| Cast iron | ≤ 240 HB | 21 | 0,170 | 0,180 | 0,210 |

| ≤ 350 HB | 18 | 0,170 | 0,180 | 0,210 | |

| Spheroidal-graphite and malleable iron | ≤ 240 HB | 18 | 0,170 | 0,180 | 0,210 |

| ≤ 350 HB | 18 | 0,170 | 0,180 | 0,210 | |

| Chilled cast iron | ≤ 350 HB | 18 | 0,070 | 0,080 | 0,090 |

| Stainless steels, sulphurated | ≤ 900 N/mm² | 9 | 0,110 | 0,130 | 0,150 |

| Stainless steels, austenitic | ≤ 1100 N/mm² | 9 | 0,070 | 0,080 | 0,090 |

| Stainless steels, martensitic | ≤ 1200 N/mm² | 9 | 0,070 | 0,080 | 0,090 |

| Titanium and titanium alloys | ≤ 850 N/mm² | 9 | 0,110 | 0,130 | 0,150 |

| ≤ 1400 N/mm² | 9 | 0,070 | 0,080 | 0,090 | |

| Special alloys | ≤ 1600 N/mm² | 7 | 0,110 | 0,130 | 0,150 |

| Hardox | Hardox 400–500, XAR 320, XAR 400 | 4 | 0,090 | 0,110 | 0,140 |

| Spring steels | ≤ 350 HB | 9 | 0,070 | 0,080 | 0,090 |

| Aluminium and aluminium alloys | ≤ 400 N/mm² | 77 | 0,210 | 0,230 | 0,260 |

| Wrought aluminium alloys | ≤ 650 N/mm² | 55 | 0,210 | 0,230 | 0,260 |

| Cast aluminium alloys ≤ 10% Si | ≤ 600 N/mm² | 33 | 0,170 | 0,180 | 0,210 |

| Cast aluminium alloys > 10% Si | ≤ 600 N/mm² | 22 | 0,170 | 0,180 | 0,210 |

| Magnesium alloys | ≤ 400 N/mm² | 77 | 0,210 | 0,230 | 0,260 |

| Copper, low-alloyed | ≤ 500 N/mm² | 33 | 0,210 | 0,230 | 0,260 |

| Brass, short-chipping | ≤ 600 N/mm² | 72 | 0,210 | 0,230 | 0,260 |

| Brass, long-chipping | ≤ 600 N/mm² | 44 | 0,210 | 0,230 | 0,260 |

| Bronze, short-chipping | ≤ 600 N/mm² | 72 | 0,210 | 0,230 | 0,260 |

| ≤ 850 N/mm² | 72 | 0,210 | 0,230 | 0,260 | |

| Bronze, long-chipping | ≤ 850 N/mm² | 44 | 0,210 | 0,230 | 0,260 |

| ≤ 1000 N/mm² | 44 | 0,210 | 0,230 | 0,260 | |

| Plastics | ≤ 150 N/mm² | 33 | 0,210 | 0,230 | 0,260 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!