Fixanchor W-FAZ PRO/HCR

Fixanchor W-FAZ PRO HCR

ANC-(W-FAZ PRO/HCR)-HCR-0-40-M8X95

Art.-no. 5930608030

EAN 4099618205446

Register now and access more than 125,000 products

Highest load values at low spacing and edge distances

Extra-large effective anchorage depths maximise the already high load values per anchor

Quick installation with fewer reinforcement hits

Extra-small effective anchorage depths minimise the tapping and embedment time

Economical and flexible application

Freely selectable embedment depth allows optimum utilisation of the anchors depending on the embedment depth and application

Minimal edge distances and spacing

Allows for fixings close to edges, small anchor plates and installation in thin concrete parts

For earthquake-proof construction

High performance under seismic action, seismic performance categories C1 and C2

European Technical Assessment ETA-20/0229 for individual fixing point, option 1, cracked and uncracked concrete:

- Static or quasi-static action (M8-M16)

- Seismic action, performance category C1 and C2 (M8-M16)

- Fire resistance R30, R60, R90, R120

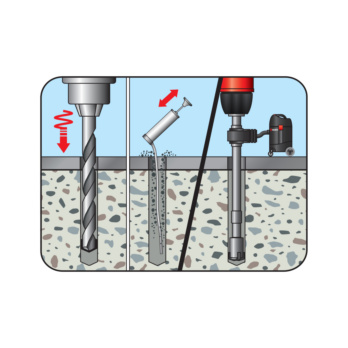

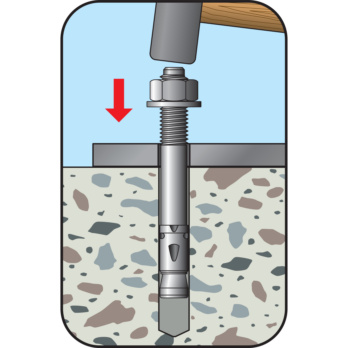

Drill the hole

Drill the hole

European Technical Assessment ETA-20/0229 for individual fixing point, option 1, cracked and uncracked concrete:

- Static or quasi-static action (M8-M16)

- Seismic action, performance category C1 and C2 (M8-M16)

- Fire resistance R30, R60, R90, R120

Datasheets(X)

For use as individual fixing point or anchors in a redundant non-structural system with approval

- In normal weight concrete C20/25 to C50/60 (cracked and uncracked concrete)

- Suitable for pre-positioned installation, in-place installation and stand-off installation

Suitable for anchoring medium to heavy loads in concrete:

Installation of e.g. metal constructions, supports, steel beams, brackets, railings, cable conduits, pipe sections etc. in highly corrosive environments

Fastenings subject to seismic activity in earthquake-prone areas

Fastenings subject to exposure to fire

The W-FAZ PRO/HCR, highly corrosion-resistant HCR steel, can be used in areas where there is a very high risk of corrosion (e.g. indoor swimming pool atmospheres, road tunnels, poorly ventilated car parks or immersion in seawater or in coastal atmospheres) and under all other conditions in accordance with EN 1993-1-4:2015-10 according to annex A, table A.3

| |

Metric anchor diameter | M8 |

Anchor length (l) | 95 mm |

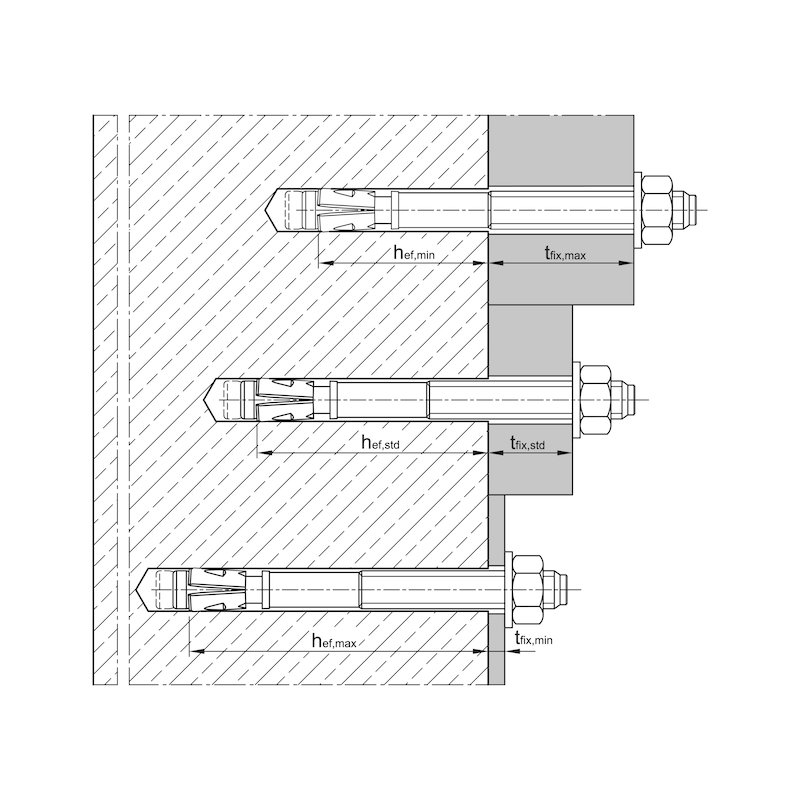

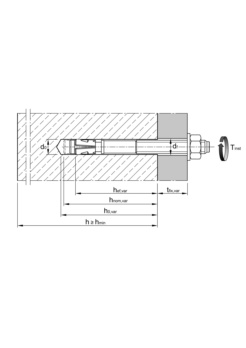

Min./max. height of the fixture (t fix) | 0-40 mm |

Attachment height standard (t fix,std) | 30 mm |

Min. effective anchoring depth (h ef, min) | 35 mm |

Max. effective anchoring depth (h ef, max) | 75 mm |

Effective anchoring depth Standard (h ef, std) | 45 mm |

Usable length (B) | 75 mm |

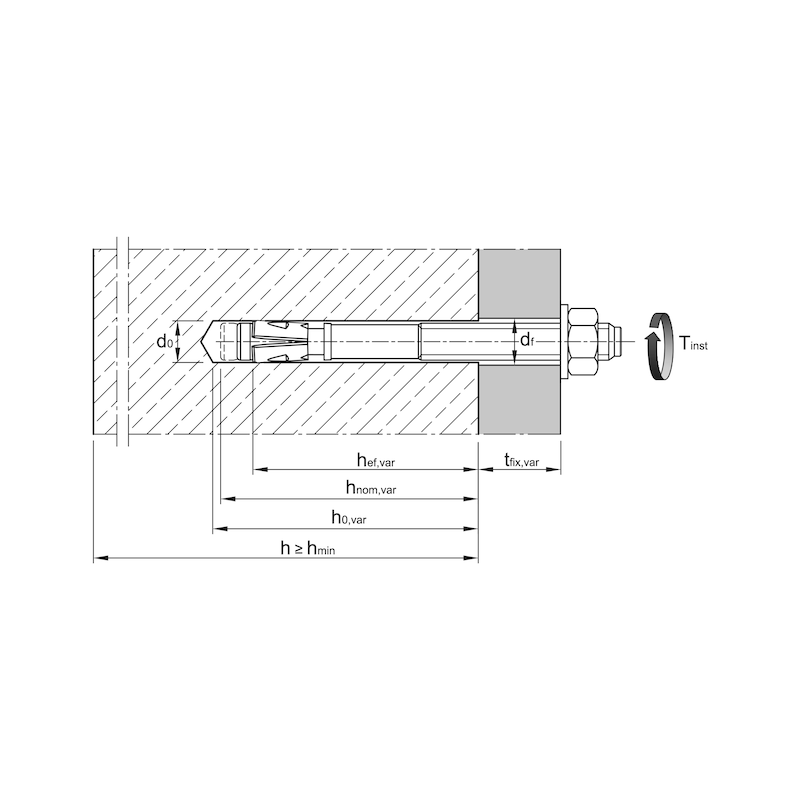

Attachment height variable (t fix ,var) | B - hef |

Disc diameter x disc thickness | 16 x 1.5 mm |

Width across flats | 13 mm |

Nominal drill-bit diameter (d 0) | 8 mm |

Drill hole depth variable (h 0, var) | hef + 8 |

Min. drill hole depth (h 0, min) | 43 mm |

Max. drill hole depth (h 0, max) | 83 mm |

Drill hole depth Standard (h 0, std) | 53 mm |

Material | Stainless steel HCR |

Surface | Coated |

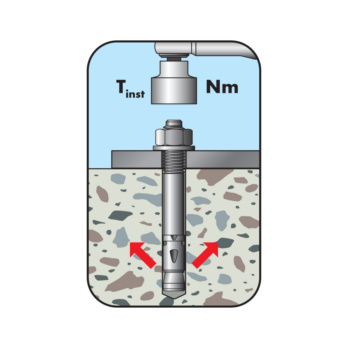

Torque during anchoring (T inst) | 15 Nm |

Through-hole in the component to be connected (d f) | 9 mm |

Thread type x anchor diameter x thread length (L th) | M8 x 53 |

Approval | ETA-20/0229 |

Seismology C1 | Yes |

Seismology C2 | Yes |

| Performance data1) of an individual anchor without influence of the edge distance in accordance with ETA-20/0229 | ||||||||||||||

| Anchor diameter | [mm] | M8 | M10 | M12 | M16 | |||||||||

| Variable effective anchorage depth | hef,var | [mm] | The effective anchorage depth can be set to anywhere between hef,min and hef,max. The Würth Technical Software can help you with the calculation. | |||||||||||

| hef,min | hef,max | hef,std | hef,min | hef,max | hef,std | hef,min | hef,max | hef,std | hef,min | hef,max | hef,std | |||

| 352) | 90 | 45 | 40 | 100 | 60 | 50 | 125 | 70 | 65 | 160 | 85 | |||

| in cracked concrete | ||||||||||||||

| Admissible tension load in concrete C 20/253) | Nadm | [kN] | 3,4 | 4,5 | 4,5 | 4,1 | 8,1 | 7,6 | 5,8 | 10,5 | 9,6 | 8,6 | 16,7 | 12,9 |

| Admissible shear load in concrete C 20/253) | Vadm | [kN] | 9,2 | 9,6 | 9,6 | 11,6 | 15,9 | 15,9 | 19,1 | 22,7 | 22,7 | 29,2 | 39,7 | 39,7 |

| Admissible bending moment | Madm | [Nm] | 15,4 | 31,4 | 56,6 | 127,4 | ||||||||

| in uncracked concrete | ||||||||||||||

| Admissible tension load in concrete C 20/253) | Nadm | [kN] | 4,9 | 9,4 | 7,1 | 5,9 | 11,9 | 10,9 | 8,3 | 20,0 | 13,7 | 12,3 | 23,8 | 18,4 |

| Admissible shear load in concrete C 20/253) | Vadm | [kN] | 9,6 | 15,9 | 22,7 | 39,7 | ||||||||

| Admissible bending moment | Madm | [Nm] | 15,4 | 31,4 | 56,6 | 127,4 | ||||||||

| Admissible load when exposed to fire (R30, R60, R90, R120), see European Technical Assessment ETA-20/0229 | ||||||||||||||

| Admissible load when exposed to fire (F180) according to the uniform temperature curve based on TR20, see expert report no. GS 6.1/20-018-1 | ||||||||||||||

| 1) The partial safety factors of the resistances stipulated in the ETA and a partial safety factor of the action of γF = 1.4 have been taken into account. Please refer to the European Technical Assessment ETA-20/0229 2) for information on combining tensile and shear loads, influence of the edge distance and groups of anchors 2) Use with effective anchorage depths hef < 40 mm is limited to anchorage of statically indeterminate systems under dry indoor room conditions 3) The concrete has normal reinforcement. Higher values are possible for higher concrete compressive strengths | ||||||||||||||

| Installation parameters1) | ||||||||||

| Anchor diameter | [mm] | M12 | M16 | |||||||

| Variable effective anchorage depths | hef | hef,var | hef,min | hef,max | hef,std | hef,var | hef,min | hef,max | hef,std | |

| [mm] | hef | 50 | 125 | 70 | hef | 65 | 160 | 85 | ||

| Embedment depth | hnom | [mm] | hef+10 | 60 | 135 | 80 | hef+14 | 79 | 174 | 99 |

| Minimum component thicknesses | hmin | [mm] | max. (1.5·hef; 100) | 100 | 187,5 | 105 | max. (1.5·hef; 120) | 120 | 240 | 127,5 |

| Minimum spacing | smin | [mm] | 50 | 65 | ||||||

| Minimum edge distance | cmin | [mm] | 55 | 65 | ||||||

| Nominal drill dia. | d0 | [mm] | 12 | 16 | ||||||

| Dia. of cutting edges | dcut ≤ | [mm] | 12,5 | 16,5 | ||||||

| Drill hole depth | h0 | [mm] | hef+10 | 60 | 135 | 80 | hef+14 | 79 | 174 | 99 |

| Through hole in the fixture | df ≤ | [mm] | 14 | 18 | ||||||

| Width across flats | AF | [mm] | 19 | 24 | ||||||

| Torque while installing anchor | Tinst = | [Nm] | 60 | 110 | ||||||

| Height of the hexagon nut | tnut | [mm] | 10 | 13 | ||||||

| Height x dia. of washer | tw x dw | [mm] | 2.5 x 24 | 3 x 30 | ||||||

| 1) For groups of anchors and anchorage close to the edge, the combinations of the minimum values (component thickness, spacing and edge distances) and the associated loads must be determined in accordance with the calculation methods of the European Technical Assessment (ETA-20/00229), depending on the effective anchorage depth. | ||||||||||

| Installation parameters1) | ||||||||||

| Anchor diameter | [mm] | M8 | M10 | |||||||

| Variable effective anchorage depths | hef | hef,var | hef,min | hef,max | hef,std | hef,var | hef,min | hef,max | hef,std | |

| [mm] | hef | 35 | 90 | 45 | hef | 40 | 100 | 60 | ||

| Embedment depth | hnom | [mm] | hef+8 | 43 | 98 | 53 | hef+9 | 49 | 109 | 69 |

| Minimum component thicknesses | hmin | [mm] | max. (1.5·hef; 80) | 80 | 135 | 80 | max. (1.5·hef; 80) | 80 | 150 | 90 |

| Minimum spacing | smin | [mm] | 35 | 40 | ||||||

| Minimum edge distance | cmin | [mm] | 40 | 45 | ||||||

| Nominal drill dia. | d0 | [mm] | 8 | 10 | ||||||

| Dia. of cutting edges | dcut ≤ | [mm] | 8,45 | 10,45 | ||||||

| Drill hole depth | h0 | [mm] | hef+8 | 43 | 98 | 53 | hef+9 | 49 | 109 | 69 |

| Through hole in the fixture | df ≤ | [mm] | 9 | 12 | ||||||

| Width across flats | AF | [mm] | 13 | 17 | ||||||

| Torque while installing anchor | Tinst = | [Nm] | 15 | 40 | ||||||

| Height of the hexagon nut | tnut | [mm] | 6,5 | 8 | ||||||

| Height x dia. of washer | tw x dw | [mm] | 1.5 x 16 | 2 x 20 | ||||||

| 1) For groups of anchors and anchorage close to the edge, the combinations of the minimum values (component thickness, spacing and edge distances) and the associated loads must be determined in accordance with the calculation methods of the European Technical Assessment (ETA-20/00229), depending on the effective anchorage depth. | ||||||||||