Fixanchor W-FAZ PRO dynamic/S

Fixanchor W-FAZ PRO dynamic steel zinc plated

ANC-(W-FAZ PRO DYN/S)-(A2K)-10-M10X100

Art.-no. 5930241010

EAN 4065746533874

Register now and access more than 125,000 products

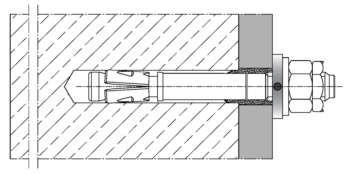

- Bolt anchors for individual attachment under fatigue loading (dynamic) in concrete

- Simple, fast and secure mounting with dynamic set

- Facilitates maximum efficiency in use

- Facilitates mounting with minimum axle and edge spacing

- High performance even with static and seismic influence and fire exposure

European Technical Assessment ETA-20/0486

- Individual attachment under fatigue-relevant cyclic stress

European Technical Assessment ETA-20/0229

- Static or quasi-static effects

- Seismic exposure, performance categories C1 and C2

- Fire load R30, R60, R90, R120

Load bearing behaviour under fire load (ETK uniform temperature time curve) - Expert opinion no. GS 6.1/20-018-1

- Fire duration 180 minutes

Robot systems (fatigue-related influences)

Robot systems (fatigue-related influences)

Tunnel ventilation (fatigue-related influences)

Tunnel ventilation (fatigue-related influences)

Conveyor belts (fatigue-related influences)

Conveyor belts (fatigue-related influences)

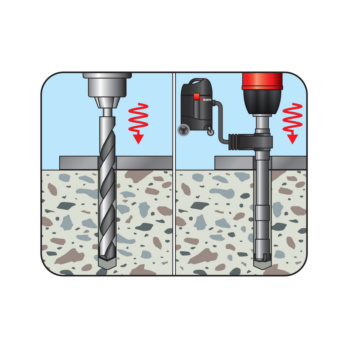

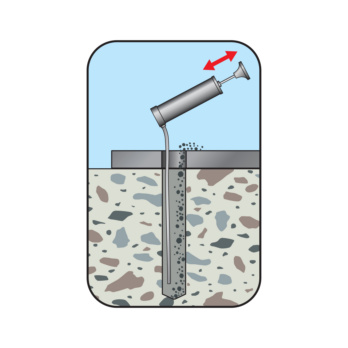

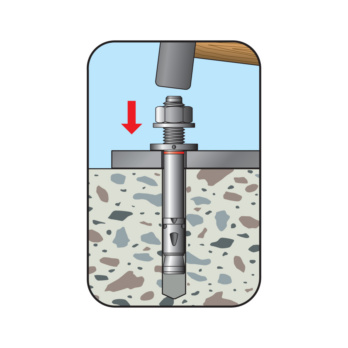

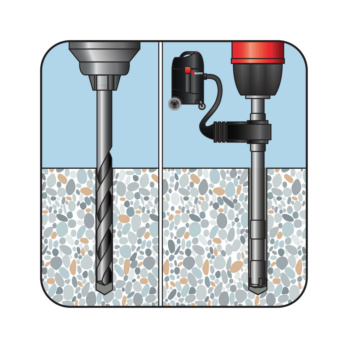

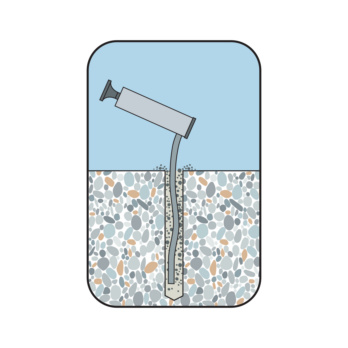

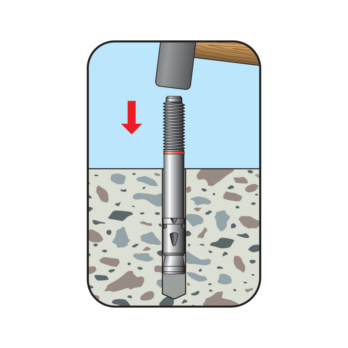

Create the drill hole

European Technical Assessment ETA-20/0486

- Individual attachment under fatigue-relevant cyclic stress

European Technical Assessment ETA-20/0229

- Static or quasi-static effects

- Seismic exposure, performance categories C1 and C2

- Fire load R30, R60, R90, R120

Load bearing behaviour under fire load (ETK uniform temperature time curve) - Expert opinion no. GS 6.1/20-018-1

- Fire duration 180 minutes

Datasheets(X)

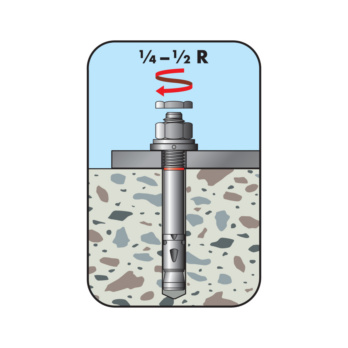

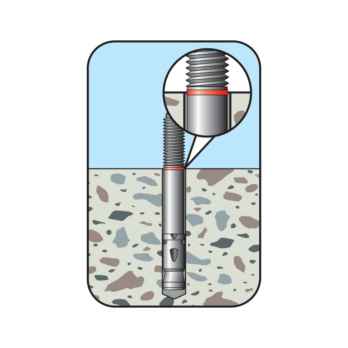

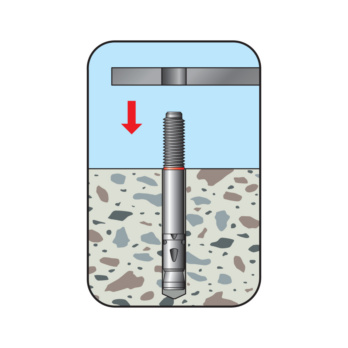

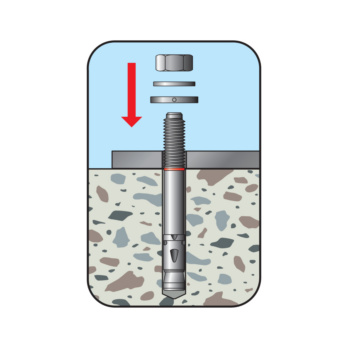

Individual attachment under fatigue loading in pre-positioned or push-through installation

Single mounting under static or quasi-static, seismic influence and fire load

Base material:

- Reinforced and non-reinforced standard concrete without fibres

- Cracked or non-cracked concrete

- Strength class C20/25 to C50/60

Heavy-duty fastenings for dynamic loads in concrete

Suitable for anchoring attachment parts under fatigue-relevant cyclical stress, e.g. crane tracks, slewing cranes, fans, machines, robots, conveyor systems, lift guide rails, traffic control systems along railways, roads and in tunnels.

| |

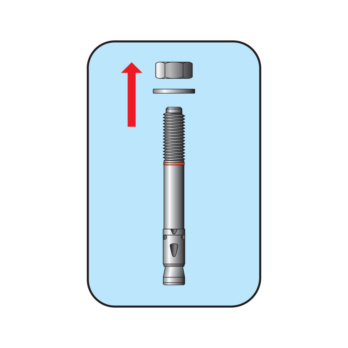

Metric anchor diameter | M10 |

Anchor length (l) | 100 mm |

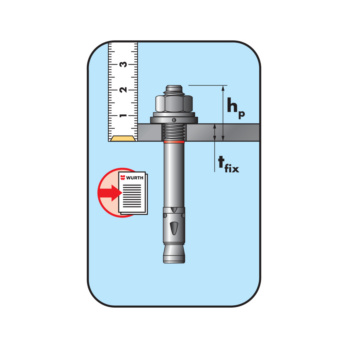

Min./max. height of the fixture (t fix) | 5-10 mm |

Attachment height (t fix) | 10 mm |

Effective anchoring depth (h ef) | 60 mm |

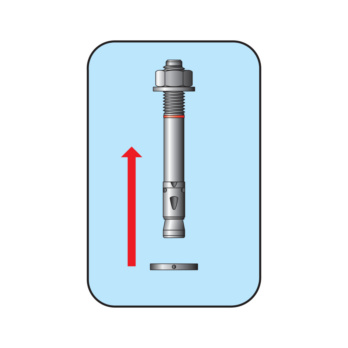

Disc diameter x disc thickness | 20 x 2 mm |

Width across flats | 17 mm |

Nominal drill-bit diameter (d 0) | 10 mm |

Drill hole depth (h 1) | 71 mm |

Material | Steel / steel |

Surface | Zinc plated |

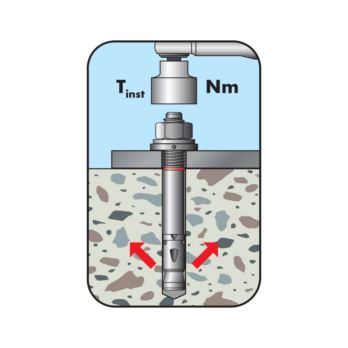

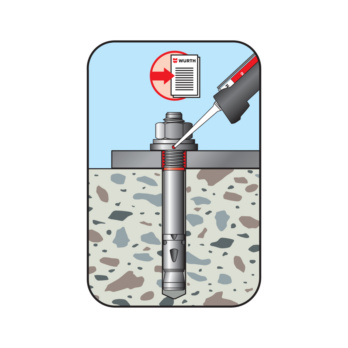

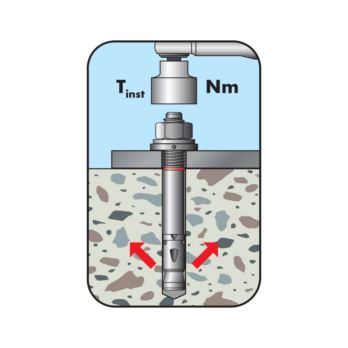

Torque during anchoring (T inst) | 40 Nm |

Through-hole in the component to be connected (d f) | 12 mm |

Thread type x anchor diameter x thread length (L th) | M10 x 26 |

Approval | ETA-20/0486, ETA-20/0229 |

Seismology C1 | Yes |

Seismology C2 | Yes |

| Performance data | |||||

| Performance data of an individual anchor without axis and edge influence under fatigue-relevant cyclic stress according to ETA-20/0486 | |||||

| Anchor diameter | [mm] | M10 | M12 | M16 | |

| Effective anchoring depth | hef | [mm] | 60 | 70 | 85 |

| Individual attachment in cracked and non-cracked concrete | |||||

| Permissible centric tension load in concrete ≥ C20/25 1) | Nperm | [kN] | 3,4 | 4,6 | 7,2 |

| Permissible transverse load in concrete ≥ C 20/25 1) | Vperm | [kN] | 1,9 | 3,0 | 5,6 |

| Static and quasi-static load, fire load and seismic load according to European Technical Assessment ETA-20/0229 | |||||

| 1) Permissible loads in accordance with EN 1992-4 of an individual anchor without influence of axis and edge distances. The overall safety factor has been taken into account. | |||||

| Installation parameters1) | |||||

| Anchor diameter | [mm] | M10 | M12 | M16 | |

| Effective anchoring depth | hef ≥ | [mm] | 60 | 70 | 85 |

| Minimum component thickness | hmin ≥ | [mm] | 90 | 105 | 127,5 |

| Minimum axis distance | smin | [mm] | 40 | 50 | 65 |

| Minimum edge spacing | cmin | [mm] | 45 | 55 | 65 |

| Nominal drill ∅ | d0 | [mm] | 10 | 12 | 16 |

| ∅ of cutting edges | dcut ≤ | [mm] | 10,45 | 12,5 | 16,5 |

| Drill hole depth 2) | h0 ≥ | [mm] | hef +9 | hef +10 | hef +14 |

| h1 ≥ | [mm] | hef +11 | hef +13 | hef +17 | |

| Through hole in the attachment | df ≤ | [mm] | 12 | 14 | 18 |

| Width across flats hexagon nut | AF | [mm] | 17 | 19 | 24 |

| With across flats locking nut | AF | [mm] | 17 | 19 | 24 |

| Torque while installing anchor | Tinst = | [Nm] | 40 | 60 | 110 |

| Overhang | hp | [mm] | 21.5 + tfix | 25.5 + tfix | 29.5 + tfix |

| Height of the hexagon nut | tnut | [mm] | 8 | 10 | 13 |

| ∅ Washer | dw x tw | [mm] | 20 x 2 | 24 x 2.5 | 30 x 3 |

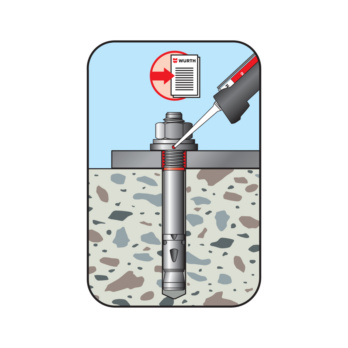

| ∅ Filling washer x height | dWIT-SHB x tWIT-SHB | [mm] | 26 x 5 | 28 x 5 | 34 x4 |

| 1) For anchor groups and anchoring close to the edge, the combinations of the minimum values (component thickness, axis and edge distances) and the associated loads must be determined in accordance with the calculation methods of European Technical Assessment (ETA-20/0486). 2) If the maximum clamping thickness tfix,max is not fully utilised, the drill hole depth can be increased by the appropriate dimension and the dowel lowered. For push-through installation, h1,d=h1+tfix,max. For pre-positioned installation, h1,v=h1+(tfix,max - tfix). The specified tfix,min must be observed. The end of the thread must always be above the concrete surface. | |||||

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!