Fixanchor internal thread W-FAZ-IG/A4 - pre-positioned installation

Fixanchor W-FAZ-IG pre-positioned install. sst A4

ANC-(W-FAZ/A4-IG)-A4-0-M10X70

Art.-no. 0904810110

EAN 4048539777990

Register now and access more than 125,000 products

- High load-bearing capacity, low centre to centre and edge clearance

- Immediate load-bearing capacity – no waiting

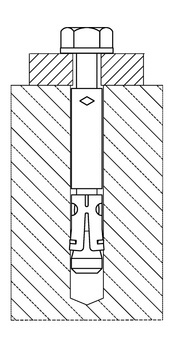

- Torque-controlled expanding A4 stainless steel anchor

- Safe expansion in cracked concrete owing to fixing anchor cone with patented plastic coating

- Countersunk screws ensure an elegant appearance for visible anchorages combined with high load-bearing capacity (e.g. railings)

- Also suitable for temporary anchorages (cotter-pin installation, e.g. flexible stadium seating – flush with surface to eliminate risk of injury)

- ETA-99/0011 for individual attachment, option 1, cracked and non-cracked concrete

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 4201-2:1977-09 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-99/0011)

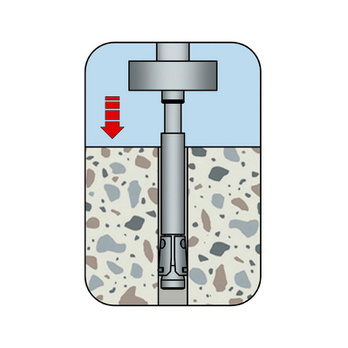

- The W-FAZ-IG Fixanchor must be inserted using the appropriate approved setting tools (anchor system).

- Hexagon head bolt, countersunk head screws, washers, countersunk washers and nuts have a special coating and are only admissible in the anchor system in accordance with ETA-99/0011. Therefore, please order these separately.

- Threaded rods may only be used if the conditions specified in approval ETA-99/0011 (material quality, dimensions, mechanical properties) are met.

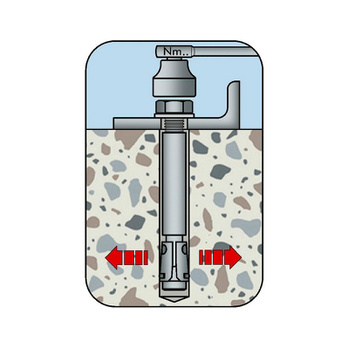

- The torque required for anchorage can be applied with Würth torque wrenches and suitable attachments (open-end socket spanners).

- A version made from highly corrosion-resistant (HCR) steel is available on request for use in areas with very high risk of corrosion (e.g. indoor swimming pool atmospheres, road tunnels, poorly ventilated car parks, or parts that are immersed in seawater or in coastal atmospheres).

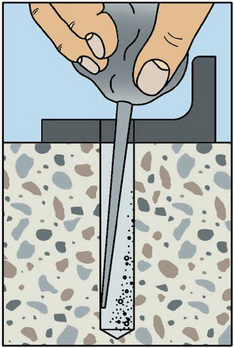

Create the drill hole

10

Knock in anchor with setting tool

Apply torque

- ETA-99/0011 for individual attachment, option 1, cracked and non-cracked concrete

- Fire resistance: F30, F60, F90 and F120; exposure to fire according to DIN 4201-2:1977-09 (uniform temperature-time curve)

- Fire resistance: R30, R60, R90 and R120; TR020 (included in ETA-99/0011)

Datasheets(X)

CAD data (available after login)

Individual attachment with approval

Standard concrete C20/25 to C50/60 (cracked and non-cracked concrete)

E.g. metal structures, metal profiles, brackets, footplates, supports, cable conduits, pipes, railings, wooden structures, roof beams, stadium seating etc.

Individual attachment without approval

Can be used in concrete < C20/25 and compression-proof natural stone

May be used in dry indoor areas and outdoors (including in industrial atmospheres and coastal areas) or in wet rooms, provided that no particularly aggressive conditions are present.

Metric anchor diameter | M10 |

Anchor length (l) | 70 mm |

Min. screw-in depth of threaded rod (Lsd) | 15 mm |

Material | Stainless steel |

Surface | Plain |

Nominal drill-bit diameter (d 0) | 12 mm |

Drill hole depth (h 1) | 90 mm |

Effective anchoring depth (h ef) | 65 mm |

| Performance data | ||||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | ||

| Admissible centric tension load3) on an individual anchor without the influence of the edge distance | Tensile zone (cracked concrete C20/254), s ≥ 3 hef, c ≥ 1.5 hef) | Nadm [kN] = C20/254) | 2,0 | 3,6 | 4,8 | 7,9 |

| Compressive zone (uncracked concrete C20/254)) s ≥ 5 hef, c ≥ 2.5 hef | Nadm [kN] = C20/254) | 4,8 | 6,3 | 7,9 | 11,9 | |

| Admissible centric shear load3) on an individual anchor without influence of the edge distance | Tensile zone and compressive zone (cracked and uncracked concrete C20/254), pre-positioned installation | Vadm [kN] = C20/254) | 3,3 | 5,3 | 6,1 | 13,5 |

| Tensile zone and compressive zone (cracked and uncracked concrete C20/254), push-through installation | 4,2 | 4,3 | 5,5 | 16,9 | ||

| Admissible bending moment for pre-positioned installation | Madm [Nm] | 4,9 | 12,0 | 23,9 | 41,9 | |

| Admissible bending moment for push-through installation | Madm [Nm] | 16,1 | 25,3 | 39,9 | 109,3 | |

| Fire resistance rating Admissible load when exposed to fire (R30, R60, R90, R120) see European Technical Approval ETA-02/0017 | ||||||

| Fire resistance rating (Direct exposure to flames in accordance with ETK DIN 4102-2:1977-09, see test report) (base material: Concrete ≥ C20/25 | F30 [kN] | 8,0 | 10,0 | 16,0 | 22,0 | |

| F60 [kN] | 2,5 | 3,5 | 8,0 | 11,0 | ||

| F90 [kN] | 1,3 | 1,8 | 5,3 | 7,3 | ||

| F120 [kN] | 0,8 | 1,2 | 4,0 | 5,5 | ||

| 3) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For information on combining tensile and shear loads and the influence of the edge distance and anchor groups, please refer to the European Technical Approval Guidelines (ETAG), Appendix C. 4) The concrete has normal reinforcement. Higher values are possible for higher concrete compressive strengths. | ||||||

| Characteristic values | |||||

| Anchor diameter [mm] | M6 | M8 | M10 | M12 | |

| Minimum member thickness | d ≥ [mm] | 100 | 120 | 130 | 160 |

| Minimum spacing cracked concrete | smin ≥ [mm] | 50 | 60 | 70 | 80 |

| Minimum spacing uncracked concrete | smin ≥ [mm] | 50 | 60 | 65 | 80 |

| Minimum spacing cracked concrete | for c ≥ [mm] | 60 | 80 | 100 | 120 |

| Minimum spacing uncracked concrete | for c ≥ [mm] | 80 | 100 | 120 | 160 |

| Minimum edge distance cracked concrete | cmin ≥ [mm] | 50 | 60 | 70 | 80 |

| Minimum edge distance uncracked concrete | cmin ≥ [mm] | 50 | 60 | 70 | 100 |

| Minimum edge distance cracked concrete | for s ≥ [mm] | 75 | 100 | 100 | 120 |

| Minimum edge distance uncracked concrete | for s ≥ [mm] | 115 | 155 | 170 | 210 |

| Effective anchorage depth | hef [mm] | 45 | 58 | 65 | 80 |

| Nominal drill diameter | d0 [mm] | 8 | 10 | 12 | 16 |

| Diameter of cutting edges | dcut ≤ [mm] | 8,45 | 10,45 | 12,5 | 16,5 |

| Drill hole depth | h1 ≥ [mm] | 60 | 75 | 90 | 105 |

| Min. length of thread engagement for threaded rod | Lsd ≥ [mm] | 9 | 12 | 15 | 18 |

| Torque while installing anchor | Tinst [Nm] type S | 15 | 40 | 50 | 100 |

| Tinst [Nm] type SK | 12 | 25 | 45 | 60 | |

| Tinst [Nm] type B | 8 | 25 | 40 | 80 | |

| Through hole in attachment Pre-positioned installation | df ≤ [mm] | 7 | 9 | 12 | 14 |

| Through hole in attachment Push-through installation | df ≤ [mm] | 9 | 12 | 14 | 18 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!