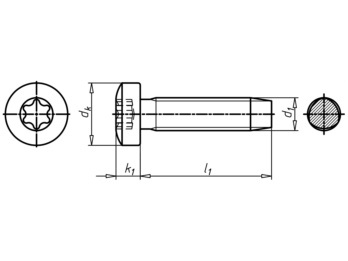

GEFU® thread-rolling screw with Taptite 2000® thread, flat head and hexalobular drive

GEFU steel 10.9 zinc nickel TX

SCR-PANHD-TT2000-10.9-TX10-(P3E)-M3,0X8

Art.-no. 020981308

EAN 4061976832824

Register now and access more than 125,000 products

Self-tapping screws form a nut thread in cast blind holes, rim holes and drilled, lasered and punched sheet metal parts. Unlike thread cutting, self-tapping does not interrupt the material structure in the receiving thread. Instead, the material is displaced and strain-hardened.

Benefits:

Cost savings

- Eliminates thread cutting

Non-cutting thread formation

Low rolling torques with greater thread flank overlap

- TRILOBULAR shape of the core diameter combined with the radius profile of the thread flanks

High clamping force

- Due to low rolling torques

High load-bearing capacity

- Due to large thread flank overlap

- Due to strain-hardened counter thread (nut thread)

Protection against loss (reduced likelihood of screw working loose)

- Play-free and self-locking thread seating

The formed thread corresponds to a standard metric thread

- Where necessary, the GEFU screw can be replaced with a metric screw.

The suitability of the GEFU for the application or component in question must be determined by preliminary testing!

GEFU (with strength class 10.9), nominal diameter ≥ M6 => see art. 0209 81... (with zinc flake coating)

Datasheets(X)

CAD data (available after login)

Examples of materials suitable for this type of non-cutting direct screwing are ductile materials such as steel (up to approx. 420 N/mm²), die-cast zinc, zinc, aluminium, copper, brass etc.

| |

Thread type x nominal diameter (d1) | M3 |

Length (l1) | 8 mm |

Head diameter (dk) | 5.6 mm |

Head height (k1) | 2.4 mm |

Head type | Flat head |

Material | Steel |

Property class | 10.9 |

Surface | Zinc nickel |

Thread type | Metric thread |

Internal drive | TX10 |

Guideline values for hole diameters | 2.8 mm |

RoHS-compliant | Yes |

Corrosion protection period | 360 h |