HPC+ end mill Turbo-Cut-Allround DIN 6527K, four blade, variable helix, short

End mill HPC+ Turbo-Cut-Allround DIN 6527K

ENDMIL-HPC+-TURBOCUT-DIN6527K-HA-D6

Art.-no. 5443500600

EAN 4065746788861

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 8012 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Non-ferrous metal |

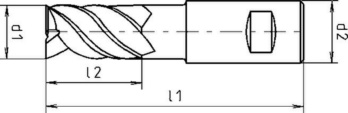

Diameter (d1) | 6 mm |

Shank diameter (d2) | 6 mm |

Standards | DIN 6527 |

Construction length | Short |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | MAXDUR |

Coolant supply | External |

Twist angle | 41-43° |

Length (l1) | 54 mm |

Cutting edge length (l2) | 10 mm |

Number of cutting edges (Z) | 4 PCS |

Corner chamfer | 0.15 mm |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Copper, Brass, Aluminium |

| Cutting values for roughing groove | |||||||||

| For dia. 6-10 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 6 | Dia. 8 | Dia. 10 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 225 | 0,038 | 0,059 | 0,044 | 0,074 | 0,058 | 0,096 |

| General structural steels | 500-850 N/mm² | E | 185 | 0,034 | 0,052 | 0,044 | 0,074 | 0,053 | 0,088 |

| Carbon steels | 850-1,000 N/mm² | E | 185 | 0,034 | 0,052 | 0,044 | 0,074 | 0,053 | 0,088 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 170 | 0,034 | 0,052 | 0,044 | 0,074 | 0,053 | 0,088 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 155 | 0,029 | 0,044 | 0,035 | 0,059 | 0,044 | 0,074 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 225 | 0,029 | 0,044 | 0,035 | 0,059 | 0,049 | 0,082 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 165 | 0,029 | 0,044 | 0,035 | 0,059 | 0,044 | 0,074 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 165 | 0,029 | 0,044 | 0,031 | 0,052 | 0,040 | 0,067 |

| Tool steels | 1,100-1,400 N/mm² | E | 170 | 0,024 | 0,037 | 0,031 | 0,052 | 0,044 | 0,074 |

| High-speed steels | < 1,300 N/mm² | E | 115 | 0,029 | 0,044 | 0,035 | 0,059 | 0,044 | 0,074 |

| Spring steels | < 1,200 N/mm² | E | 102 | 0,024 | 0,037 | 0,027 | 0,044 | 0,035 | 0,059 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 81 | 0,029 | 0,045 | 0,034 | 0,056 | 0,047 | 0,079 |

| Sulphurated stainless steels | < 700 N/mm² | E | 94 | 0,029 | 0,045 | 0,034 | 0,056 | 0,047 | 0,079 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 92 | 0,029 | 0,044 | 0,035 | 0,059 | 0,044 | 0,074 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 125 | 0,034 | 0,052 | 0,044 | 0,074 | 0,053 | 0,088 |

| Cast iron | > 260 HB | E | 102 | 0,034 | 0,052 | 0,035 | 0,059 | 0,046 | 0,077 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 350 | 0,054 | 0,080 | 0,068 | 0,102 | 0,077 | 0,116 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 332 | 0,054 | 0,080 | 0,068 | 0,102 | 0,077 | 0,116 |

| Low-alloy copper | < 450 N/mm² | E | 95 | 0,039 | 0,059 | 0,058 | 0,087 | 0,073 | 0,109 |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae (cutting thickness radial) = 0.10-0.45xd1 |

| ap (cutting thickness axial) = 1xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for roughing contour | |||||

| For dia. 25 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 25 | |||||

| Min. | Max. | ||||

| Steels | |||||

| General structural steels | < 500 N/mm² | E | 290 | 0,134 | 0,202 |

| General structural steels | 500-850 N/mm² | E | 230 | 0,128 | 0,192 |

| Carbon steels | 850-1,000 N/mm² | E | 230 | 0,128 | 0,192 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 230 | 0,124 | 0,186 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 185 | 0,100 | 0,150 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 290 | 0,124 | 0,186 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 225 | 0,100 | 0,150 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 225 | 0,100 | 0,150 |

| Tool steels | 1,100-1,400 N/mm² | E | 225 | 0,113 | 0,169 |

| High-speed steels | < 1,300 N/mm² | E | 125 | 0,094 | 0,150 |

| Spring steels | < 1,200 N/mm² | E | 125 | 0,088 | 0,132 |

| Stainless steels | |||||

| Austentic stainless steels | < 700 N/mm² | E | 147 | 0,108 | 0,162 |

| Sulphurated stainless steels | < 700 N/mm² | E | 170 | 0,108 | 0,162 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 120 | 0,100 | 0,150 |

| Titanium, titanium alloys | < 900 N/mm² | E | 65 | 0,100 | 0,150 |

| Cast metals | |||||

| Cast iron | < 180 HB | E | 165 | 0,128 | 0,192 |

| Cast iron | > 260 HB | E | 165 | 0,128 | 0,192 |

| Non-ferrous metals | |||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 406 | 0,228 | 0,343 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 370 | 0,228 | 0,343 |

| Low-alloy copper | < 450 N/mm² | E | 115 | 0,228 | 0,343 |

| Cutting values for roughing contour | |||||||||

| For dia. 12-20 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 12 | Dia. 16 | Dia. 20 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 290 | 0,086 | 0,130 | 0,103 | 0,081 | 0,125 | 0,187 |

| General structural steels | 500-850 N/mm² | E | 230 | 0,082 | 0,122 | 0,097 | 0,081 | 0,114 | 0,171 |

| Carbon steels | 850-1,000 N/mm² | E | 230 | 0,082 | 0,122 | 0,097 | 0,081 | 0,114 | 0,171 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 230 | 0,082 | 0,122 | 0,097 | 0,081 | 0,114 | 0,171 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 185 | 0,065 | 0,097 | 0,076 | 0,065 | 0,086 | 0,130 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 290 | 0,071 | 0,106 | 0,086 | 0,065 | 0,108 | 0,163 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 225 | 0,065 | 0,097 | 0,076 | 0,065 | 0,086 | 0,130 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 225 | 0,054 | 0,081 | 0,065 | 0,058 | 0,086 | 0,130 |

| Tool steels | 1,100-1,400 N/mm² | E | 225 | 0,065 | 0,097 | 0,076 | 0,058 | 0,097 | 0,146 |

| High-speed steels | < 1,300 N/mm² | E | 125 | 0,061 | 0,097 | 0,071 | 0,065 | 0,081 | 0,130 |

| Spring steels | < 1,200 N/mm² | E | 125 | 0,049 | 0,074 | 0,054 | 0,049 | 0,076 | 0,113 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 147 | 0,070 | 0,106 | 0,084 | 0,060 | 0,096 | 0,144 |

| Sulphurated stainless steels | < 700 N/mm² | E | 170 | 0,070 | 0,106 | 0,084 | 0,060 | 0,096 | 0,144 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 120 | 0,065 | 0,097 | 0,076 | 0,065 | 0,086 | 0,130 |

| Titanium, titanium alloys | < 900 N/mm² | E | 65 | 0,065 | 0,097 | 0,076 | 0,065 | 0,086 | 0,130 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 165 | 0,082 | 0,122 | 0,097 | 0,081 | 0,114 | 0,171 |

| Cast iron | > 260 HB | E | 165 | 0,082 | 0,122 | 0,097 | 0,081 | 0,114 | 0,171 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 406 | 0,121 | 0,181 | 0,134 | 0,141 | 0,188 | 0,282 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 370 | 0,121 | 0,181 | 0,134 | 0,141 | 0,188 | 0,282 |

| Low-alloy copper | < 450 N/mm² | E | 115 | 0,121 | 0,181 | 0,134 | 0,121 | 0,188 | 0,282 |

| Cutting values for finishing contour | |||||||||

| For dia. 6-10 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 6 | Dia. 8 | Dia. 10 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 340 | 0,030 | 0,047 | 0,035 | 0,059 | 0,046 | 0,077 |

| General structural steels | 500-850 N/mm² | E | 275 | 0,027 | 0,042 | 0,035 | 0,059 | 0,043 | 0,071 |

| Carbon steels | 850-1,000 N/mm² | E | 280 | 0,027 | 0,042 | 0,035 | 0,059 | 0,043 | 0,071 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 275 | 0,027 | 0,042 | 0,035 | 0,059 | 0,043 | 0,071 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 228 | 0,022 | 0,035 | 0,028 | 0,047 | 0,035 | 0,059 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 340 | 0,022 | 0,035 | 0,028 | 0,047 | 0,040 | 0,066 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 265 | 0,022 | 0,035 | 0,028 | 0,047 | 0,035 | 0,059 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 265 | 0,022 | 0,035 | 0,025 | 0,042 | 0,032 | 0,054 |

| Tool steels | 1,100-1,400 N/mm² | E | 265 | 0,019 | 0,030 | 0,025 | 0,042 | 0,035 | 0,059 |

| High-speed steels | < 1,300 N/mm² | E | 155 | 0,022 | 0,035 | 0,028 | 0,047 | 0,035 | 0,059 |

| Spring steels | < 1,200 N/mm² | E | 155 | 0,019 | 0,030 | 0,021 | 0,035 | 0,028 | 0,047 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 161 | 0,022 | 0,035 | 0,026 | 0,044 | 0,037 | 0,061 |

| Sulphurated stainless steels | < 700 N/mm² | E | 195 | 0,022 | 0,035 | 0,026 | 0,044 | 0,037 | 0,061 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 130 | 0,022 | 0,035 | 0,028 | 0,047 | 0,035 | 0,059 |

| Titanium, titanium alloys | < 900 N/mm² | E | 85 | 0,012 | 0,035 | 0,028 | 0,047 | 0,035 | 0,059 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 155 | 0,027 | 0,042 | 0,035 | 0,059 | 0,043 | 0,071 |

| Cast iron | > 260 HB | E | 105 | 0,027 | 0,042 | 0,035 | 0,059 | 0,043 | 0,071 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 440 | 0,052 | 0,078 | 0,066 | 0,099 | 0,075 | 0,113 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 410 | 0,052 | 0,078 | 0,066 | 0,099 | 0,075 | 0,113 |

| Low-alloy copper | < 450 N/mm² | E | 130 | 0,038 | 0,057 | 0,056 | 0,085 | 0,071 | 0,106 |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae (cutting thickness radial) = 1xd1 |

| ap (cutting thickness axial) = 1xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for roughing groove | |||||

| For dia. 25 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 25 | |||||

| Min. | Max. | ||||

| Steels | |||||

| General structural steels | < 500 N/mm² | E | 225 | 0,115 | 0,191 |

| General structural steels | 500-850 N/mm² | E | 185 | 0,106 | 0,176 |

| Carbon steels | 850-1,000 N/mm² | E | 185 | 0,106 | 0,176 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 170 | 0,106 | 0,176 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 155 | 0,084 | 0,141 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 225 | 0,102 | 0,169 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 165 | 0,093 | 0,155 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 165 | 0,084 | 0,141 |

| Tool steels | 1,100-1,400 N/mm² | E | 170 | 0,093 | 0,155 |

| High-speed steels | < 1,300 N/mm² | E | 115 | 0,085 | 0,141 |

| Spring steels | < 1,200 N/mm² | E | 102 | 0,071 | 0,118 |

| Stainless steels | |||||

| Austentic stainless steels | < 700 N/mm² | E | 81 | 0,091 | 0,152 |

| Sulphurated stainless steels | < 700 N/mm² | E | 94 | 0,091 | 0,152 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 92 | 0,084 | 0,141 |

| Cast metals | |||||

| Cast iron | < 180 HB | E | 125 | 0,102 | 0,170 |

| Cast iron | > 260 HB | E | 102 | 0,096 | 0,160 |

| Non-ferrous metals | |||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 350 | 0,165 | 0,247 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 332 | 0,165 | 0,247 |

| Low-alloy copper | < 450 N/mm² | E | 95 | 0,165 | 0,247 |

| Cutting values for roughing groove | |||||||||

| For dia. 12-20 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 12 | Dia. 16 | Dia. 20 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 225 | 0,071 | 0,118 | 0,084 | 0,141 | 0,102 | 0,169 |

| General structural steels | 500-850 N/mm² | E | 185 | 0,066 | 0,111 | 0,079 | 0,132 | 0,093 | 0,155 |

| Carbon steels | 850-1,000 N/mm² | E | 185 | 0,066 | 0,111 | 0,079 | 0,132 | 0,093 | 0,155 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 170 | 0,066 | 0,111 | 0,079 | 0,132 | 0,093 | 0,155 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 155 | 0,049 | 0,082 | 0,053 | 0,088 | 0,071 | 0,118 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 225 | 0,058 | 0,096 | 0,071 | 0,118 | 0,088 | 0,147 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 165 | 0,053 | 0,088 | 0,061 | 0,102 | 0,071 | 0,118 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 165 | 0,044 | 0,074 | 0,053 | 0,088 | 0,071 | 0,118 |

| Tool steels | 1,100-1,400 N/mm² | E | 170 | 0,053 | 0,088 | 0,061 | 0,102 | 0,079 | 0,132 |

| High-speed steels | < 1,300 N/mm² | E | 115 | 0,053 | 0,088 | 0,061 | 0,102 | 0,079 | 0,132 |

| Spring steels | < 1,200 N/mm² | E | 102 | 0,040 | 0,067 | 0,044 | 0,074 | 0,061 | 0,102 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 81 | 0,059 | 0,099 | 0,071 | 0,118 | 0,081 | 0,135 |

| Sulphurated stainless steels | < 700 N/mm² | E | 94 | 0,059 | 0,099 | 0,071 | 0,118 | 0,081 | 0,135 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 92 | 0,053 | 0,088 | 0,061 | 0,102 | 0,071 | 0,118 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 125 | 0,066 | 0,111 | 0,079 | 0,132 | 0,093 | 0,155 |

| Cast iron | > 260 HB | E | 102 | 0,058 | 0,096 | 0,071 | 0,118 | 0,088 | 0,147 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 350 | 0,087 | 0,131 | 0,097 | 0,145 | 0,135 | 0,203 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 332 | 0,087 | 0,131 | 0,097 | 0,145 | 0,135 | 0,203 |

| Low-alloy copper | < 450 N/mm² | E | 95 | 0,087 | 0,131 | 0,097 | 0,145 | 0,135 | 0,203 |

| Cutting values for roughing contour | |||||||||

| For dia. 6-10 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 6 | Dia. 8 | Dia. 10 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 290 | 0,043 | 0,065 | 0,054 | 0,081 | 0,071 | 0,106 |

| General structural steels | 500-850 N/mm² | E | 230 | 0,038 | 0,058 | 0,054 | 0,081 | 0,065 | 0,097 |

| Carbon steels | 850-1,000 N/mm² | E | 230 | 0,038 | 0,058 | 0,054 | 0,081 | 0,065 | 0,097 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 230 | 0,038 | 0,058 | 0,054 | 0,081 | 0,065 | 0,097 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 185 | 0,033 | 0,049 | 0,043 | 0,065 | 0,054 | 0,081 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 290 | 0,033 | 0,049 | 0,043 | 0,065 | 0,060 | 0,091 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 225 | 0,033 | 0,049 | 0,043 | 0,065 | 0,054 | 0,081 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 225 | 0,033 | 0,049 | 0,038 | 0,058 | 0,049 | 0,074 |

| Tool steels | 1,100-1,400 N/mm² | E | 225 | 0,028 | 0,041 | 0,038 | 0,058 | 0,054 | 0,081 |

| High-speed steels | < 1,300 N/mm² | E | 125 | 0,033 | 0,049 | 0,041 | 0,065 | 0,051 | 0,081 |

| Spring steels | < 1,200 N/mm² | E | 125 | 0,028 | 0,041 | 0,032 | 0,049 | 0,043 | 0,065 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 147 | 0,032 | 0,048 | 0,040 | 0,060 | 0,056 | 0,084 |

| Sulphurated stainless steels | < 700 N/mm² | E | 170 | 0,032 | 0,048 | 0,040 | 0,060 | 0,056 | 0,084 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 120 | 0,033 | 0,049 | 0,043 | 0,065 | 0,054 | 0,081 |

| Titanium, titanium alloys | < 900 N/mm² | E | 65 | 0,033 | 0,049 | 0,043 | 0,065 | 0,054 | 0,081 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 165 | 0,038 | 0,058 | 0,054 | 0,081 | 0,065 | 0,097 |

| Cast iron | > 260 HB | E | 165 | 0,038 | 0,058 | 0,054 | 0,081 | 0,065 | 0,097 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 406 | 0,074 | 0,111 | 0,094 | 0,141 | 0,107 | 0,161 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 370 | 0,074 | 0,111 | 0,094 | 0,141 | 0,107 | 0,161 |

| Low-alloy copper | < 450 N/mm² | E | 115 | 0,054 | 0,082 | 0,081 | 0,121 | 0,101 | 0,151 |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae (cutting thickness radial) = 0.025xd1 |

| ap (cutting thickness axial) = 1xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for finishing contour | |||||

| For dia. 25 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 25 | |||||

| Min. | Max. | ||||

| Steels | |||||

| General structural steels | < 500 N/mm² | E | 340 | 0,088 | 0,147 |

| General structural steels | 500-850 N/mm² | E | 275 | 0,084 | 0,140 |

| Carbon steels | 850-1,000 N/mm² | E | 280 | 0,084 | 0,140 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 275 | 0,081 | 0,136 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 228 | 0,066 | 0,109 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 340 | 0,081 | 0,136 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 265 | 0,066 | 0,109 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 265 | 0,066 | 0,109 |

| Tool steels | 1,100-1,400 N/mm² | E | 265 | 0,074 | 0,123 |

| High-speed steels | < 1,300 N/mm² | E | 155 | 0,066 | 0,109 |

| Spring steels | < 1,200 N/mm² | E | 155 | 0,058 | 0,096 |

| Stainless steels | |||||

| Austentic stainless steels | < 700 N/mm² | E | 161 | 0,071 | 0,118 |

| Sulphurated stainless steels | < 700 N/mm² | E | 195 | 0,071 | 0,118 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 130 | 0,066 | 0,109 |

| Titanium, titanium alloys | < 900 N/mm² | E | 85 | 0,066 | 0,109 |

| Cast metals | |||||

| Cast iron | < 180 HB | E | 155 | 0,084 | 0,140 |

| Cast iron | > 260 HB | E | 105 | 0,084 | 0,140 |

| Non-ferrous metals | |||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 440 | 0,160 | 0,240 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 410 | 0,160 | 0,240 |

| Low-alloy copper | < 450 N/mm² | E | 130 | 0,160 | 0,240 |

| Cutting values for finishing contour | |||||||||

| For dia. 12-20 | |||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||

| Dia. 12 | Dia. 16 | Dia. 20 | |||||||

| Min. | Max. | Min. | Max. | Min. | Max. | ||||

| Steels | |||||||||

| General structural steels | < 500 N/mm² | E | 340 | 0,057 | 0,095 | 0,068 | 0,113 | 0,082 | 0,137 |

| General structural steels | 500-850 N/mm² | E | 275 | 0,054 | 0,089 | 0,064 | 0,106 | 0,075 | 0,125 |

| Carbon steels | 850-1,000 N/mm² | E | 280 | 0,054 | 0,089 | 0,064 | 0,106 | 0,075 | 0,125 |

| Unalloyed heat-treated steels | 850-1,000 N/mm² | E | 275 | 0,054 | 0,089 | 0,064 | 0,106 | 0,075 | 0,125 |

| Alloyed heat-treated steels | 1,000-1,200 N/mm² | E | 228 | 0,043 | 0,071 | 0,050 | 0,083 | 0,057 | 0,095 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 340 | 0,046 | 0,077 | 0,057 | 0,095 | 0,071 | 0,119 |

| Alloyed case-hardening steels | < 700 N/mm² | E | 265 | 0,043 | 0,071 | 0,050 | 0,083 | 0,057 | 0,095 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 265 | 0,035 | 0,059 | 0,043 | 0,071 | 0,057 | 0,095 |

| Tool steels | 1,100-1,400 N/mm² | E | 265 | 0,043 | 0,071 | 0,050 | 0,083 | 0,064 | 0,106 |

| High-speed steels | < 1,300 N/mm² | E | 155 | 0,043 | 0,071 | 0,050 | 0,083 | 0,057 | 0,095 |

| Spring steels | < 1,200 N/mm² | E | 155 | 0,032 | 0,054 | 0,035 | 0,059 | 0,050 | 0,083 |

| Stainless steels | |||||||||

| Austentic stainless steels | < 700 N/mm² | E | 161 | 0,046 | 0,077 | 0,055 | 0,092 | 0,063 | 0,105 |

| Sulphurated stainless steels | < 700 N/mm² | E | 195 | 0,046 | 0,077 | 0,055 | 0,092 | 0,063 | 0,105 |

| Martensitic stainless steels | < 1,100 N/mm² | E | 130 | 0,043 | 0,071 | 0,050 | 0,083 | 0,057 | 0,095 |

| Titanium, titanium alloys | < 900 N/mm² | E | 85 | 0,043 | 0,071 | 0,050 | 0,083 | 0,057 | 0,095 |

| Cast metals | |||||||||

| Cast iron | < 180 HB | E | 155 | 0,054 | 0,089 | 0,064 | 0,106 | 0,075 | 0,125 |

| Cast iron | > 260 HB | E | 105 | 0,054 | 0,089 | 0,064 | 0,106 | 0,075 | 0,125 |

| Non-ferrous metals | |||||||||

| Aluminium, aluminium alloys | < 400 N/mm² | E | 440 | 0,085 | 0,127 | 0,094 | 0,141 | 0,132 | 0,197 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 410 | 0,085 | 0,127 | 0,094 | 0,141 | 0,132 | 0,197 |

| Low-alloy copper | < 450 N/mm² | E | 130 | 0,085 | 0,127 | 0,094 | 0,141 | 0,132 | 0,197 |