HPC end mill with corner radius, Speedcut 4.0 titanium, long, optional, five cutting edges, uneven angle of twist gradient, with internal cooling, HB shank

Mill. cut. SC4.0 Titanium WN-L Z5 IC AERODUR FG HB

ENDMIL-HPC-4.0-TITAN-Z5-FG-HB-D12X2,5

Art.-no. 5443313960

EAN 4065746568838

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Solid carbide high-performance end mill particularly suitable for machining titanium, Inconel and special alloys. Different spiral angles produce smooth, vibration-free running and an excellent surface quality. Very high machining performance thanks to the perfect interaction of material, geometry and coating.

Product information

Datasheets(X)

| |

Product code | 8137 |

Material to be processed | Titanium, Nickel, Special alloy |

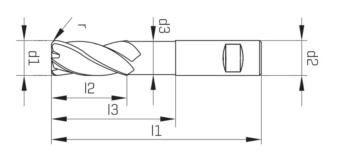

Diameter (d1) | 12 mm |

Shank diameter (d2) | 12 mm |

Clearance diameter (d3) | 11.5 mm |

Standards | CS |

Construction length | Long |

Shank style | Cylindrical DIN 6535-HB |

Cutting material | SC |

Surface | AERODUR |

Coolant supply | Internal |

Twist angle | 40° Vario |

Corner radius (R) | 2.5 mm |

Length (l1) | 83 mm |

Cutting edge length (l2) | 26 mm |

Clearance length (l3) | 38 mm |

Number of cutting edges (Z) | 5 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Titanium, Titanium alloys, Special alloys |

| For circular roughing | |||||||||||

| For dia. 3-6 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 125 | 0,087 | 0,139 | 0,091 | 0,145 | 0,095 | 0,151 | 0,096 | 0,154 |

| 900-1,500 N/mm² | E | 115 | 0,083 | 0,138 | 0,086 | 0,144 | 0,090 | 0,150 | 0,092 | 0,153 | |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| Cutting thickness ae (radial) = 0.02xd1 |

| Cutting thickness ap (axial) = 1.8xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For finishing contour | |||||

| For dia. 20 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 20 | |||||

| min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 103 | 0,043 | 0,065 |

| 900-1,500 N/mm² | E | 95 | 0,046 | 0,069 | |

| For finishing contour | |||||||||||

| For dia. 8-16 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 8 | Dia. 10 | Dia. 12 | Dia. 16 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 103 | 0,021 | 0,032 | 0,027 | 0,041 | 0,032 | 0,048 | 0,038 | 0,057 |

| 900-1,500 N/mm² | E | 95 | 0,022 | 0,034 | 0,029 | 0,043 | 0,034 | 0,051 | 0,040 | 0,060 | |

| Cutting values | |||||||||||

| For roughing contour | |||||||||||

| For dia. 3-6 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 95 | 0,014 | 0,020 | 0,015 | 0,019 | 0,017 | 0,026 | 0,021 | 0,032 |

| 900-1,500 N/mm² | E | 85 | 0,014 | 0,022 | 0,016 | 0,020 | 0,018 | 0,028 | 0,022 | 0,034 | |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| Cutting thickness ae (radial) = 0.70-075xd1 |

| Cutting thickness ap (axial) = 1.8xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For circular roughing | |||||

| For dia. 20 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 20 | |||||

| min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 125 | 0,130 | 0,208 |

| 900-1,500 N/mm² | E | 115 | 0,124 | 0,206 | |

| For circular roughing | |||||||||||

| For dia. 8-16 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 8 | Dia. 10 | Dia. 12 | Dia. 16 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 125 | 0,105 | 0,168 | 0,113 | 0,181 | 0,121 | 0,194 | 0,126 | 0,202 |

| 900-1,500 N/mm² | E | 115 | 0,100 | 0,166 | 0,108 | 0,180 | 0,116 | 0,193 | 0,120 | 0,200 | |

| For finishing contour | |||||||||||

| For dia. 3-6 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 103 | 0,011 | 0,016 | 0,012 | 0,018 | 0,014 | 0,021 | 0,017 | 0,025 |

| 900-1,500 N/mm² | E | 95 | 0,012 | 0,017 | 0,013 | 0,019 | 0,015 | 0,022 | 0,018 | 0,027 | |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| Cutting thickness ae (radial) = 0.1-0.12xd1 |

| Cutting thickness ap (axial) = 1.25xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| For roughing contour | |||||

| For dia. 20 | |||||

| Material designation | Tensile strength | Cooling | vc | fz | |

| Dia. 20 | |||||

| min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 95 | 0,054 | 0,081 |

| 900-1,500 N/mm² | E | 85 | 0,058 | 0,086 | |

| For roughing contour | |||||||||||

| For dia. 8-16 | |||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||||||

| Dia. 8 | Dia. 10 | Dia. 12 | Dia. 16 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | ||||

| TiAl alloy | < 900 N/mm² | E | 95 | 0,026 | 0,039 | 0,034 | 0,051 | 0,040 | 0,060 | 0,047 | 0,071 |

| 900-1,500 N/mm² | E | 85 | 0,028 | 0,042 | 0,036 | 0,054 | 0,042 | 0,064 | 0,050 | 0,076 | |