HPT end mill, short, centre-cutting DIN 844K

End mill HSCo-SPM DIN 844K Z3-6 2xD type HF TiAlN

ENDMIL-DIN844K-HSCO-SPM-TN-D18,0MM

Art.-no. 5443600867

EAN 4055375879122

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Produced from new SPM substrate with very high cobalt proportion. Combining the hardness of solid carbide with the toughness of PM steel. This cutter is ideal for meeting the highest requirements in terms of cutting performance and increasing cutting volume in stainless steels.

Product information

Datasheets(X)

| |

Product code | 2117 |

Material to be processed | Steel, Stainless steel |

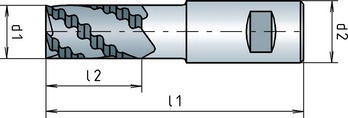

Diameter (d1) | 18 mm |

Shank diameter (d2) | 16 mm |

Standards | DIN 844 |

Construction length | Short |

Shank style | Cylindrical DIN 1835-B |

Cutting material | HSCo-SPM |

Surface | TiAlN |

Coolant supply | External |

Twist angle | 30° |

Length (l1) | 92 mm |

Cutting edge length (l2) | 32 mm |

Number of cutting edges | 5 PCS |

Corner chamfer | 0.30 mm |

Tolerance of cutting edge diameter | k12 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Stainless steels < 850 N/mm², Stainless steels > 850 N/mm² |

| Key | ||

| E = emulsion | ae = 0.5xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for roughing contour | |||||||

| For dia. 16 to dia. 32 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 16-19.9 | Dia. 20-23.9 | Dia. 24-31.9 | Dia. 32 | ||||

| General structural steels | < 500 N/mm² | E | 83 | 0,060 | 0,076 | 0,094 | 0,120 |

| 500-850 N/mm² | E | 69 | 0,053 | 0,067 | 0,083 | 0,106 | |

| Carbon steels | < 850 N/mm² | E | 74 | 0,053 | 0,067 | 0,083 | 0,106 |

| 850-1000 N/mm² | E | 69 | 0,053 | 0,067 | 0,083 | 0,106 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 69 | 0,053 | 0,067 | 0,083 | 0,106 |

| 700-850 N/mm² | E | 64 | 0,053 | 0,067 | 0,083 | 0,106 | |

| 850-1000 N/mm² | E | 51 | 0,053 | 0,067 | 0,083 | 0,106 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 51 | 0,053 | 0,067 | 0,083 | 0,106 |

| 1000-1200 N/mm² | E | 46 | 0,060 | 0,076 | 0,094 | 0,120 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 64 | 0,053 | 0,067 | 0,083 | 0,106 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 60 | 0,053 | 0,067 | 0,083 | 0,106 |

| 1000-1200 N/mm² | E | 51 | 0,060 | 0,076 | 0,094 | 0,120 | |

| Nitriding steels | < 1000 N/mm² | E | 51 | 0,053 | 0,067 | 0,083 | 0,106 |

| 1000-1200 N/mm² | E | 41 | 0,060 | 0,076 | 0,094 | 0,120 | |

| Tool steels | < 850 N/mm² | E | 41 | 0,053 | 0,067 | 0,083 | 0,106 |

| 850-1100 N/mm² | E | 37 | 0,060 | 0,076 | 0,094 | 0,120 | |

| High-speed steels | 850-1200 N/mm² | E | 26 | 0,060 | 0,076 | 0,094 | 0,120 |

| Spring steels | < 1200 N/mm² | E | 21 | 0,060 | 0,076 | 0,094 | 0,120 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 41 | 0,053 | 0,067 | 0,083 | 0,106 |

| Stainless steels, austenitic | < 700 N/mm² | E | 32 | 0,053 | 0,067 | 0,083 | 0,106 |

| < 850 N/mm² | E | 23 | 0,053 | 0,067 | 0,083 | 0,106 | |

| Stainless steels, sulphurated | < 700 N/mm130 | E | 18 | 0,060 | 0,076 | 0,094 | 0,120 |

| Special alloys | < 1200 N/mm² | E | 14 | 0,060 | 0,076 | 0,094 | 0,120 |

| Cutting values for roughing contour | |||||||

| For dia. 6 to dia. 15.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 6-7.9 | Dia. 8-9.9 | Dia. 10-11.9 | Dia. 12-15.9 | ||||

| General structural steels | < 500 N/mm² | E | 83 | 0,020 | 0,028 | 0,037 | 0,044 |

| 500-850 N/mm² | E | 69 | 0,017 | 0,024 | 0,033 | 0,038 | |

| Carbon steels | < 850 N/mm² | E | 74 | 0,017 | 0,024 | 0,033 | 0,038 |

| 850-1000 N/mm² | E | 69 | 0,017 | 0,024 | 0,033 | 0,038 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 69 | 0,017 | 0,024 | 0,033 | 0,038 |

| 700-850 N/mm² | E | 64 | 0,017 | 0,024 | 0,033 | 0,038 | |

| 850-1000 N/mm² | E | 51 | 0,017 | 0,024 | 0,033 | 0,038 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 51 | 0,017 | 0,024 | 0,033 | 0,038 |

| 1000-1200 N/mm² | E | 46 | 0,020 | 0,028 | 0,037 | 0,044 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 64 | 0,017 | 0,024 | 0,033 | 0,038 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 60 | 0,017 | 0,024 | 0,033 | 0,038 |

| 1000-1200 N/mm² | E | 51 | 0,020 | 0,028 | 0,037 | 0,044 | |

| Nitriding steels | < 1000 N/mm² | E | 51 | 0,017 | 0,024 | 0,033 | 0,038 |

| 1000-1200 N/mm² | E | 41 | 0,020 | 0,028 | 0,037 | 0,044 | |

| Tool steels | < 850 N/mm² | E | 41 | 0,017 | 0,024 | 0,033 | 0,038 |

| 850-1100 N/mm² | E | 37 | 0,020 | 0,028 | 0,037 | 0,044 | |

| High-speed steels | 850-1200 N/mm² | E | 26 | 0,020 | 0,028 | 0,037 | 0,044 |

| Spring steels | < 1200 N/mm² | E | 21 | 0,020 | 0,028 | 0,037 | 0,044 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 41 | 0,017 | 0,024 | 0,033 | 0,038 |

| Stainless steels, austenitic | < 700 N/mm² | E | 32 | 0,017 | 0,024 | 0,033 | 0,038 |

| < 850 N/mm² | E | 23 | 0,017 | 0,024 | 0,033 | 0,038 | |

| Stainless steels, sulphurated | < 700 N/mm130 | E | 18 | 0,020 | 0,028 | 0,037 | 0,044 |

| Special alloys | < 1200 N/mm² | E | 14 | 0,020 | 0,028 | 0,037 | 0,044 |

| Key | ||

| E = emulsion | ae = 1xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. Full grooves are not possible for diameters greater than 20 mm, as the power consumed is too high. | ||

| Cutting values for roughing groove | ||||||

| For dia. 12 to dia. 20 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 12-15.9 | Dia. 16-19.9 | Dia. 20 | ||||

| General structural steels | < 500 N/mm² | E | 83 | 0,035 | 0,040 | 0,050 |

| 500-850 N/mm² | E | 69 | 0,035 | 0,040 | 0,046 | |

| Carbon steels | < 850 N/mm² | E | 74 | 0,035 | 0,040 | 0,046 |

| 850-1000 N/mm² | E | 69 | 0,035 | 0,040 | 0,046 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 69 | 0,035 | 0,040 | 0,046 |

| 700-850 N/mm² | E | 64 | 0,035 | 0,040 | 0,046 | |

| 850-1000 N/mm² | E | 51 | 0,035 | 0,040 | 0,046 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 51 | 0,035 | 0,040 | 0,046 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 64 | 0,035 | 0,040 | 0,046 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 60 | 0,035 | 0,040 | 0,046 |

| Nitriding steels | < 1000 N/mm² | E | 51 | 0,035 | 0,040 | 0,046 |

| Tool steels | < 850 N/mm² | E | 41 | 0,035 | 0,040 | 0,046 |

| 850-1100 N/mm² | E | 37 | 0,035 | 0,040 | 0,050 | |

| Stainless steels, sulphurated | < 700 N/mm² | E | 41 | 0,035 | 0,040 | 0,046 |

| Stainless steels, austenitic | < 700 N/mm² | E | 32 | 0,035 | 0,040 | 0,046 |

| < 850 N/mm² | E | 23 | 0,035 | 0,040 | 0,046 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 18 | 0,035 | 0,040 | 0,050 |

| Special alloys | < 1200 N/mm² | E | 14 | 0,035 | 0,040 | 0,050 |

| Aluminium, aluminium alloys | < 530 N/mm² | E | 221 | 0,012 | 0,020 | 0,030 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 138 | 0,017 | 0,029 | 0,042 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 147 | 0,012 | 0,020 | 0,030 |

| Cutting values for roughing groove | ||||||

| For dia. 6 to dia. 11.9 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 6-7.9 | Dia. 8-9.9 | Dia. 10-11.9 | ||||

| General structural steels | < 500 N/mm² | E | 83 | 0,010 | 0,014 | 0,023 |

| 500-850 N/mm² | E | 69 | 0,010 | 0,014 | 0,023 | |

| Carbon steels | < 850 N/mm² | E | 74 | 0,010 | 0,014 | 0,023 |

| 850-1000 N/mm² | E | 69 | 0,010 | 0,014 | 0,023 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 69 | 0,010 | 0,014 | 0,023 |

| 700-850 N/mm² | E | 64 | 0,010 | 0,014 | 0,023 | |

| 850-1000 N/mm² | E | 51 | 0,010 | 0,014 | 0,023 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 51 | 0,010 | 0,014 | 0,023 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 64 | 0,010 | 0,014 | 0,023 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 60 | 0,010 | 0,014 | 0,023 |

| Nitriding steels | < 1000 N/mm² | E | 51 | 0,010 | 0,014 | 0,023 |

| Tool steels | < 850 N/mm² | E | 41 | 0,010 | 0,014 | 0,023 |

| 850-1100 N/mm² | E | 37 | 0,010 | 0,014 | 0,023 | |

| Stainless steels, sulphurated | < 700 N/mm² | E | 41 | 0,010 | 0,014 | 0,023 |

| Stainless steels, austenitic | < 700 N/mm² | E | 32 | 0,010 | 0,014 | 0,023 |

| < 850 N/mm² | E | 23 | 0,010 | 0,014 | 0,023 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 18 | 0,010 | 0,014 | 0,023 |

| Special alloys | < 1200 N/mm² | E | 14 | 0,010 | 0,014 | 0,023 |

| Aluminium, aluminium alloys | < 530 N/mm² | E | 221 | 0,005 | 0,006 | 0,008 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 138 | 0,007 | 0,008 | 0,012 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 147 | 0,005 | 0,006 | 0,008 |