HPT extra-short twist drill bit DIN 1897

Twist drill HSCo-PM DIN 1897 3xD type Forte TiAlN

DRL-SPRL-MET-DIN1897-TIALN-HPT-D6,9MM

Art.-no. 5443810044

EAN 4062856117116

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

With Forte special profile for optimised chip formation. Particularly suitable for use on machining centres and turning machines. Wide application range in all, preferably long-chipping materials up to approx. 1300 N/mm², also for stainless austenitic steels. Suitable for dry machining in steel materials.

Product information

Datasheets(X)

| |

Product code | 900 |

Material to be processed | Steel, Cast metal, Stainless steel |

Standard / drilling depth | DIN 1897 / 3xD |

Design | Extra short |

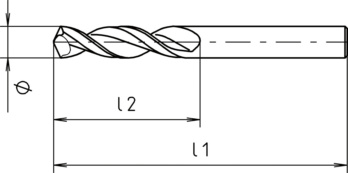

Diameter (Ø) | 6.9 mm |

Length (l1) | 74 mm |

Chip flute length (l2) | 34 mm |

Shank diameter | 6.9 mm |

Shank style | Cylindrical |

Surface | TiAlN |

Cutting material | HSCo-PM |

Angle of the tip | 130 Degree |

Suitable for tensile strength up to | 1300 N/mm² |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm² |

| Cutting values for HSS drill bits | |||||||

| For dia. 2.8 to dia. 12 | |||||||

| Material designation | Tensile strength | vc | f | ||||

| from | to | Dia. 2.8-4.9 | Dia. 5-7.9 | Dia. 8-11.9 | Dia. 12 | ||

| General structural steels | < 500 N/mm² | 70 | 90 | 0,050 | 0,130 | 0,220 | 0,270 |

| 500-850 N/mm² | 70 | 90 | 0,050 | 0,130 | 0,220 | 0,270 | |

| Carbon steels | < 850 N/mm² | 70 | 90 | 0,050 | 0,130 | 0,220 | 0,270 |

| 850-1000 N/mm² | 40 | 60 | 0,030 | 0,080 | 0,110 | 0,170 | |

| Unalloyed heat-treated steels | < 700 N/mm² | 40 | 60 | 0,030 | 0,080 | 0,110 | 0,170 |

| 700-850 N/mm² | 40 | 60 | 0,030 | 0,080 | 0,110 | 0,170 | |

| 850-1000 N/mm² | 40 | 50 | 0,030 | 0,060 | 0,100 | 0,150 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 |

| 1000-1200 N/mm² | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 | |

| Unalloyed case-hardening steels | < 750 N/mm² | 50 | 70 | 0,030 | 0,080 | 0,110 | 0,170 |

| Alloyed case-hardening steels | < 1000 N/mm² | 40 | 60 | 0,020 | 0,050 | 0,090 | 0,130 |

| 1000-1200 N/mm² | 40 | 50 | 0,020 | 0,050 | 0,090 | 0,130 | |

| Nitriding steels | < 1000 N/mm² | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 |

| 1000-1200 N/mm² | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 | |

| General structural steels | < 500 N/mm131 | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 |

| 500-850 N/mm131 | 30 | 40 | 0,020 | 0,050 | 0,090 | 0,130 | |

| General structural steels | < 500 N/mm131 | 25 | 35 | 0,020 | 0,050 | 0,090 | 0,130 |

| 500-850 N/mm131 | 25 | 35 | 0,020 | 0,050 | 0,090 | 0,130 | |

| Carbon steels | < 850 N/mm131 | 10 | 20 | 0,020 | 0,050 | 0,090 | 0,130 |

| 850-1000 N/mm131 | 10 | 15 | 0,020 | 0,050 | 0,090 | 0,130 | |

| Stainless steels, sulphurated | < 700 N/mm² | 18 | 28 | 0,020 | 0,050 | 0,090 | 0,130 |

| Stainless steels, austenitic | < 700 N/mm² | 15 | 25 | 0,020 | 0,050 | 0,090 | 0,130 |

| < 850 N/mm² | 15 | 25 | 0,020 | 0,050 | 0,090 | 0,130 | |

| Stainless steels, martensitic | < 1100 N/mm² | 12 | 20 | 0,020 | 0,050 | 0,090 | 0,130 |

| Special alloys | < 1200 N/mm² | 10 | 15 | 0,020 | 0,050 | 0,090 | 0,130 |

| Cast iron | < 180 HB | 70 | 90 | 0,050 | 0,130 | 0,220 | 0,270 |

| > 180 HB | 50 | 70 | 0,040 | 0,110 | 0,170 | 0,220 | |

| Nodular graphite, malleable iron | > 180 HB | 70 | 90 | 0,050 | 0,130 | 0,220 | 0,270 |

| > 260 HB | 50 | 70 | 0,040 | 0,110 | 0,170 | 0,220 | |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |