HSCo8 AlCrN annular cutter assortment 7 pieces

Core drill bit HSCo8 AlCrN assortment 7 pieces

CREDRL-MET-SORT-HSCO8-ALCRN-55MM-7PCS

Art.-no. 0630942607

EAN 4062856037186

Register now and access more than 125,000 products

Outstanding performance compared to similar uncoated core drill bits

- Significantly higher service life

- Up to 60% greater cutting speed

- Considerably faster drilling progress

AlCrN multilayer wear-protection coating and 8% cobalt alloy

- Extremely high temperature resistance of up to 1050°C

- Very high coating hardness of 3000 HV

- Multilayer construction for optimum chip removal and improved cutting properties (prevents material wear)

For process reliability in almost all materials

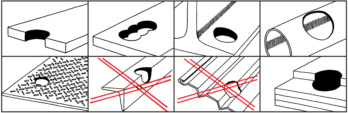

Exact guidance, no slippage

Problem-free drilling on curved surfaces and pipes

No predrilling required, no formation of burrs

Eliminates need for pre- and post-machining

- Unlike the twist drill, the core drill bit does not machine the entire bore diameter, but rather only a thin material ring. The drill core is ejected by an ejector pin using spring tension; this is included in the scope of delivery. The drilling times of core drill bits are therefore up to ten times shorter than those of twist drills.

- Sufficient continuous cooling during the entire drilling process considerably increases the service life of the core drill. Do not use in a dry state.

- See the overview tables for core drill bits/material assignments as well as cutting values

- Wear appropriate protective equipment when using the sanding tip, such as Eye protection, hearing protection, protective gloves

- Set aside loose clothing or jewellery that could get caught in moving parts

- The core drill bits must not be used manually

- Before use, please ensure that the tool rotates properly and that the clamping function on the tool drive works correctly

Datasheets(X)

- With Weldon shank ∅ 19 mm for use on mobile magnetic drills or stationary drills for creating large holes up to 50 mm in diameter and a cutting depth of max. 55 mm

- Fein drills with QuickIn mount can be used with an adapter

- Application on stationary drills with Morse taper is possible using the appropriate mount holder

- Insert the ejector pin into the core drill bit

- Push the core drill bit into the mount holder of the drill unit and tighten the hexagon socket screws

- The core drill bit is automatically locked into place when using quick-action mounts

- Make sure the core drill bit is sitting cleanly in the mount

- Putting the drill under lateral load during use may cause the tool to break

- Fix the drill unit into the right position for drilling — make sure the drill unit has a stable footing

- If necessary, secure the drill unit before drilling using a safety strap, especially for use on vertical surfaces and overhead work

- Pay attention to the speed table and use coolant

- Drill carefully (without centre punching and pre-drilling), pay attention to an even feed and even rotation speed throughout the entire drilling process

- Remove chips and drill core after each drilling operation

- Caution: Risk of injury, chips and drill core may be very hot and sharp

Number of pieces in assortment/set | 7 |

Material to be processed | Steel, Stainless steel, Cast metal, Non-ferrous metal, Hard and tough material |

Surface | AlCrN |

Cutting material | HSCo8 |

Cutting depth | 55 mm |

Length | 84.6 mm |

Shank style | Weldon |

Quality | ZEBRA-Premium |

Service life (points system) | 4 of 4 points |

Drilling speed (point system) | 4 of 4 points |

Bore hole quality (point system) | 4 of 4 points |

Versatility (points system) | 4 of 4 points |

Drilling behaviour (point system) | 4 of 4 points |

| Cutting values | |||||||||

| For dia. 12.0-20.0 | |||||||||

| Material designation | Tensile strength | from dia. 12.0 | from dia. 16.0 | from dia. 20.0 | |||||

| vc | n | n | n | ||||||

| from | to | from | to | from | to | from | to | ||

| Steels | |||||||||

| General structural steels | ≤ 850 N/mm² | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Unalloyed quenched and tempered steels | ≤ 850 N/mm² | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Low-alloy quenched and tempered steels | ≤ 850 N/mm² | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Unalloyed quenched and tempered steels | ≤ 1,000 N/mm² | 10 | 15 | 265 | 398 | 199 | 298 | 159 | 239 |

| Low-alloy quenched and tempered steels | ≤ 1,000 N/mm² | 10 | 15 | 265 | 398 | 199 | 298 | 159 | 239 |

| Alloyed quenched and tempered steels | ≤ 1,300 | 8 | 10 | 212 | 265 | 159 | 199 | 127 | 159 |

| Nitriding steels | ≤ 1,300 | 8 | 10 | 212 | 265 | 159 | 199 | 127 | 159 |

| Tool steels | ≤ 1,300 | 8 | 10 | 212 | 265 | 159 | 199 | 127 | 159 |

| High-speed steels | ≤ 1,300 | 8 | 10 | 212 | 265 | 159 | 199 | 127 | 159 |

| Stainless steels | |||||||||

| Stainless steels | ≤ 1,200 | 10 | 15 | 265 | 398 | 199 | 298 | 159 | 239 |

| Titanium | ≤ 850 | 10 | 15 | 265 | 398 | 199 | 298 | 159 | 239 |

| Special alloys | ≤ 1,200 | 10 | 15 | 265 | 398 | 199 | 298 | 159 | 239 |

| Cast metals | |||||||||

| Cast iron | ≤ 350 HB | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Non-ferrous metals | |||||||||

| Aluminium | ≤ 450 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium alloys | ≤ 450 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium wrought alloys | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium cast alloys <= 10 % Si | ≤ 600 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium cast alloys >10 % Si | ≤ 600 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Magnesium alloys | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Low-alloy copper | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Short-chipping brass | ≤ 850 | 20 | 25 | 398 | 531 | 298 | 398 | 239 | 318 |

| Long-chipping brass | ≤ 850 | 20 | 25 | 398 | 531 | 298 | 398 | 239 | 318 |

| Short-chipping bronze | ≤ 850 | 20 | 25 | 398 | 531 | 298 | 398 | 239 | 318 |

| Long-chipping bronze | ≤ 1,000 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Plastics | |||||||||

| Thermosetting plastics | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 | |

| Thermoplastic plastics | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 | |

| Key |

| vc = cutting speed [m/min] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

CREDRL-MET-HSCO8-ALCRN-DRLDP55MM-D14MM

CREDRL-MET-HSCO8-ALCRN-DRLDP55MM-D16MM

CREDRL-MET-HSCO8-ALCRN-DRLDP55MM-D18MM

CREDRL-MET-HSCO8-ALCRN-DRLDP55MM-D22MM

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!