HSCo8 TiCN Speedtap Universal thread former with internal cooling

HSCo8 TiCN Speedtap Universal thr. former with IC

THRFORM-HSCO8-DIN2174-TICN-IC-M16

Art.-no. 5443211600

EAN 4062856444090

Register now and access more than 125,000 products

- Caution: A special predrilling diameter larger than in thread cutting and with tighter tolerances is required for thread forming! The suitable core hole diameter is stored as a technical characteristic for all thread formers.

- In thread forming, the main job of the cooling lubricant is lubrication. The more lubrication used with the highest possible grease content, the longer the service life. The lubrication also affects the surface quality of the thread!

- Please note that for thread forming, you will need approx. two times as much performance (torque) compared to thread tapping. The means that capacity should be considered when using thread-cutting devices.

Datasheets(X)

| |

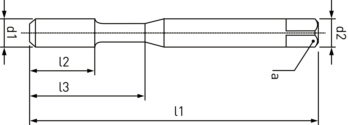

Product code | 4699 |

Thread type | Metric thread |

Material to be processed | Steel, Copper, Brass, Aluminium, Plastic |

Hole type | Clearance/blind hole ≤ 3xD |

Suitable for machine type | Milling/drill center |

Thread type x nominal diameter | M16 |

Pitch | 2 mm |

Length | 110 mm |

Thread length | 20 mm |

Shank diameter | 12 mm |

Size of square | 9 mm |

Number of cutting edges | 8 PCS |

Core hole diameter | 15.1 mm |

Cutting material | HSCo8 |

DIN | 2174 |

Surface | TiCN |

Form | C |

Shank style | Cylindrical with square drive |

Tolerance of thread former | ISO 2X (6HX) |

Suitable for tensile strength up to | 1300 N/mm² |

Coolant supply | Internal |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Copper, Brass, Aluminium, Plastics |

| Legend |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | ||||||

| For M45 | ||||||

| Material designation | Tensile strength | M45 | ||||

| vc | n | f | ||||

| from | to | from | to | |||

| Steels | ||||||

| Steels | < 400 N/mm² | 20 | 30 | 141 | 212 | 4,5 |

| Steels | < 850 N/mm² | 20 | 30 | 141 | 212 | 4,5 |

| Steels | < 1100 N/mm² | 8 | 15 | 57 | 106 | 4,5 |

| Steels | < 1300 N/mm² | 8 | 15 | 57 | 106 | 4,5 |

| Non-ferrous metals | ||||||

| Copper, brass | 20 | 40 | 141 | 283 | 4,5 | |

| Aluminium | 20 | 40 | 141 | 283 | 4,5 | |

| Cutting values | ||||||||||||

| For M6-M10 | ||||||||||||

| Material designation | Tensile strength | M6 | M8 | M10 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Steels | < 400 N/mm² | 20 | 30 | 1061 | 1592 | 1 | 796 | 1194 | 1,25 | 637 | 955 | 1,5 |

| Steels | < 850 N/mm² | 20 | 30 | 1061 | 1592 | 1 | 796 | 1194 | 1,25 | 637 | 955 | 1,5 |

| Steels | < 1100 N/mm² | 8 | 15 | 424 | 796 | 1 | 318 | 597 | 1,25 | 255 | 477 | 1,5 |

| Steels | < 1300 N/mm² | 8 | 15 | 424 | 796 | 1 | 318 | 597 | 1,25 | 255 | 477 | 1,5 |

| Non-ferrous metals | ||||||||||||

| Copper, brass | 20 | 40 | 1061 | 2123 | 1 | 796 | 1592 | 1,25 | 637 | 1273 | 1,5 | |

| Aluminium | 20 | 40 | 1061 | 2123 | 1 | 796 | 1592 | 1,25 | 637 | 1273 | 1,5 | |

| Cutting values | ||||||||||||

| For M36 - M42 | ||||||||||||

| Material designation | Tensile strength | M36 | M39 | M42 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Steels | < 400 N/mm² | 20 | 30 | 177 | 265 | 4 | 163 | 245 | 4 | 152 | 227 | 4,5 |

| Steels | < 850 N/mm² | 20 | 30 | 177 | 265 | 4 | 163 | 245 | 4 | 152 | 227 | 4,5 |

| Steels | < 1100 N/mm² | 8 | 15 | 71 | 133 | 4 | 65 | 122 | 4 | 61 | 114 | 4,5 |

| Steels | < 1300 N/mm² | 8 | 15 | 71 | 133 | 4 | 65 | 122 | 4 | 61 | 114 | 4,5 |

| Non-ferrous metals | ||||||||||||

| Copper, brass | 20 | 40 | 177 | 354 | 4 | 163 | 326 | 4 | 152 | 303 | 4,5 | |

| Aluminium | 20 | 40 | 177 | 354 | 4 | 163 | 326 | 4 | 152 | 303 | 4,5 | |

| Cutting values | ||||||||||||

| For M27 - M33 | ||||||||||||

| Material designation | Tensile strength | M27 | M30 | M33 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Steels | < 400 N/mm² | 20 | 30 | 236 | 354 | 3 | 212 | 318 | 3,5 | 193 | 289 | 3,5 |

| Steels | < 850 N/mm² | 20 | 30 | 236 | 354 | 3 | 212 | 318 | 3,5 | 193 | 289 | 3,5 |

| Steels | < 1100 N/mm² | 8 | 15 | 94 | 177 | 3 | 85 | 159 | 3,5 | 77 | 145 | 3,5 |

| Steels | < 1300 N/mm² | 8 | 15 | 94 | 177 | 3 | 85 | 159 | 3,5 | 77 | 145 | 3,5 |

| Non-ferrous metals | ||||||||||||

| Copper, brass | 20 | 40 | 236 | 472 | 3 | 212 | 424 | 3,5 | 193 | 386 | 3,5 | |

| Aluminium | 20 | 40 | 236 | 472 | 3 | 212 | 424 | 3,5 | 193 | 386 | 3,5 | |

| Cutting values | ||||||||||||

| For M18-M24 | ||||||||||||

| Material designation | Tensile strength | M18 | M20 | M24 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Steels | < 400 N/mm² | 20 | 30 | 354 | 531 | 2,5 | 318 | 477 | 2,5 | 265 | 398 | 3 |

| Steels | < 850 N/mm² | 20 | 30 | 354 | 531 | 2,5 | 318 | 477 | 2,5 | 265 | 398 | 3 |

| Steels | < 1100 N/mm² | 8 | 15 | 141 | 265 | 2,5 | 127 | 239 | 2,5 | 106 | 199 | 3 |

| Steels | < 1300 N/mm² | 8 | 15 | 141 | 265 | 2,5 | 127 | 239 | 2,5 | 106 | 199 | 3 |

| Non-ferrous metals | ||||||||||||

| Copper, brass | 20 | 40 | 354 | 707 | 2,5 | 318 | 637 | 2,5 | 265 | 531 | 3 | |

| Aluminium | 20 | 40 | 354 | 707 | 2,5 | 318 | 637 | 2,5 | 265 | 531 | 3 | |

| Cutting values | ||||||||||||

| For M12-M16 | ||||||||||||

| Material designation | Tensile strength | M12 | M14 | M16 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| Steels | < 400 N/mm² | 20 | 30 | 531 | 796 | 1,75 | 455 | 682 | 2 | 398 | 597 | 2 |

| Steels | < 850 N/mm² | 20 | 30 | 531 | 796 | 1,75 | 455 | 682 | 2 | 398 | 597 | 2 |

| Steels | < 1100 N/mm² | 8 | 15 | 212 | 398 | 1,75 | 182 | 341 | 2 | 159 | 298 | 2 |

| Steels | < 1300 N/mm² | 8 | 15 | 212 | 398 | 1,75 | 182 | 341 | 2 | 159 | 298 | 2 |

| Non-ferrous metals | ||||||||||||

| Copper, brass | 20 | 40 | 531 | 1061 | 1,75 | 455 | 909 | 2 | 398 | 796 | 2 | |

| Aluminium | 20 | 40 | 531 | 1061 | 1,75 | 455 | 909 | 2 | 398 | 796 | 2 | |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!