HSS DIN 338 SMART STEP twist drill bit

Twist drill HSS DIN 338 SMART STEP

DRL-TWST-MET-DIN338-HSS-SMARTSTEP-D2,0MM

Art.-no. 0624930200

EAN 4061975499004

Register now and access more than 125,000 products

The original SMART STEP: the first twist drill bit with stepped drill bit tip geometry (from dia. 2.5 mm)

Precise, circular holes

Extremely comfortable drilling

- Eliminates pre-drilling, precise spot drilling without running off-centre

- Angled drilling possible

- Simple drilling or enlarging of an existing drill hole

Significantly faster than conventional twist drill bits with point thinning

Ideal for drilling out rivets and stud bolts

The first twist drill bit to enable precise, hand-held drilling up to dia. 20 mm without pre-drilling; even enables precise holes up to dia. 26.5 mm without pre-drilling when used in a box column drill

Shank reduced to dia. 12.7 mm from > 13.0 mm drill bit diameter for use in all standard 3-jaw drill chucks

3-flat shank (from dia. 4 mm)

- No spinning in the drill chuck: faster, more comfortable working

- Optimal power transmission

- Protects the drill chuck from damage

- Minimal effort required to loosen and tighten the drill chuck

Product packaging made from 100 % PCR (recycled plastic from household waste) and 100 % recyclable

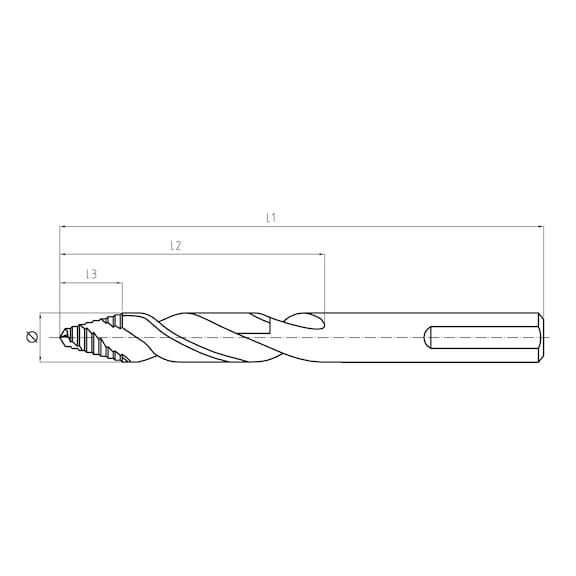

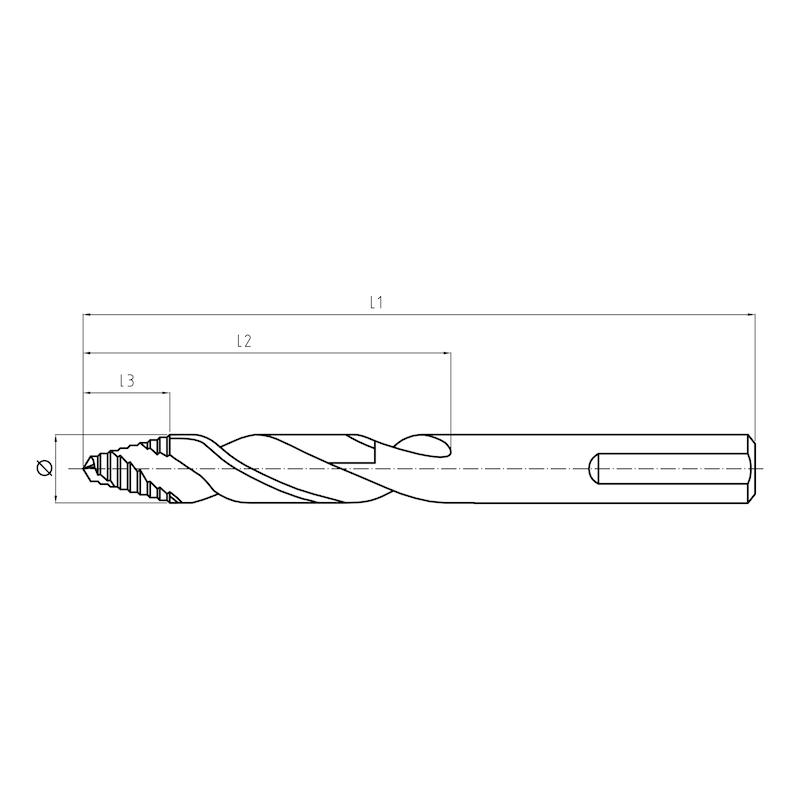

For blind bores, please note the extended drill tip (see dimension l3)!

Datasheets(X)

- Perfect for rivet holes, drilling out stud bolts, for drilling sheet metal and thin-walled profile materials (e.g. aluminium/window profiles).

- High quality of drill holes and significantly longer service life compared to conventional twist wood drill bits for drilling holes in wood.

- Ideal for high-precision, comfortable and quick work in solid materials (e.g. in steel with strength of up to 1000 N/mm², aluminium and plastics).

| |

Suitable for machine type | Drill, Cordless screwdrivers, Pedestal drilling machine |

Material to be processed | Steel, Cast iron, Non-ferrous metal, Wood, Hardwood |

Quality | ZEBRA-Premium |

Standard / drilling depth | DIN 338 / 5xD |

Diameter (Ø) | 2.0 mm |

Length (l1) | 49 mm |

Chip flute length (l2) | 24 mm |

Shank diameter | 2.0 mm |

Shank style | Cylindrical |

Surface | Multiple refined |

Cutting material | HSS |

Type | SMART STEP |

Service life (points system) | 3 of 4 points |

Drilling speed (point system) | 4 of 4 points |

Bore hole quality (point system) ( ) | 4 of 4 points |

Versatility (points system) | 3 of 4 points |

Drilling behaviour (point system) | 4 of 4 points |

Suitable for drill (points system) | 4 of 4 points |

Suitable for cordless drills (points system) | 4 of 4 points |

Suitable for upright drilling machine (points system) | 4 of 4 points |

Self-centring | Yes |

Suitable for tensile strength up to | 1000 N/mm² |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Cast iron, Ductile iron, Malleable cast iron, Magnesium alloys, Copper, low-alloyed, Brass, short-chipping, Brass, long-chipping, Plastics, thermoset, Plastics, thermoplastic |

| Cutting values | ||||||||||||

| For dia. 1.0-2.5 | ||||||||||||

| Material designation | Tensile strength | From dia. 1.0 | From dia. 2.0 | From dia. 2.5 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 25 | 37 | 7,958 | 9,549 | 0,016 | 3,979 | 4,775 | 0,050 | 3,183 | 3,820 | 0,063 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 7,958 | 9,549 | 0,016 | 3,979 | 4,775 | 0,050 | 3,183 | 3,820 | 0,063 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 7,958 | 9,549 | 0,016 | 3,979 | 4,775 | 0,050 | 3,183 | 3,820 | 0,063 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 7,003 | 7,958 | 0,014 | 3,501 | 3,979 | 0,040 | 2,801 | 3,183 | 0,050 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 7,003 | 7,958 | 0,014 | 3,501 | 3,979 | 0,040 | 2,801 | 3,183 | 0,050 |

| Alloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 20 | 3,183 | 5,093 | 0,012 | 1,592 | 2,546 | 0,032 | 1,273 | 2,037 | 0,040 |

| Nitriding steels | ≤ 1,000 N/mm² | 10 | 20 | 3,183 | 5,093 | 0,012 | 1,592 | 2,546 | 0,032 | 1,273 | 2,037 | 0,040 |

| Tool steels | ≤ 1,000 N/mm² | 10 | 20 | 3,183 | 5,093 | 0,012 | 1,592 | 2,546 | 0,032 | 1,273 | 2,037 | 0,040 |

| High-speed steels | ≤ 1,000 N/mm² | 10 | 20 | 3,183 | 5,093 | 0,012 | 1,592 | 2,546 | 0,032 | 1,273 | 2,037 | 0,040 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 22 | 31 | 8,913 | 10,186 | 0,018 | 4,456 | 5,093 | 0,063 | 3,565 | 4,074 | 0,080 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 22 | 31 | 7,003 | 7,958 | 0,018 | 3,501 | 3,979 | 0,063 | 2,801 | 3,183 | 0,080 |

| Non-ferrous metal | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 12,732 | 19,099 | 0,018 | 6,366 | 9,549 | 0,063 | 5,093 | 7,639 | 0,080 |

| Plastics | ||||||||||||

| Plastics, thermosetting | 20 | 37 | 6,366 | 9,549 | 0,016 | 3,183 | 4,775 | 0,050 | 2,546 | 3,820 | 0,063 | |

| Plastics, thermoplastic | 20 | 37 | 4,777 | 9,549 | 0,016 | 3,183 | 4,775 | 0,050 | 2,546 | 3,820 | 0,063 | |

| Wood | ||||||||||||

| Softwood | 25 | 37 | 7,958 | 9,549 | 0,016 | 3,979 | 4,775 | 0,050 | 3,183 | 3,820 | 0,063 | |

| Hardwood | ||||||||||||

| Hardwood | 22 | 31 | 7,003 | 7,958 | 0,014 | 3,501 | 3,979 | 0,040 | 2,801 | 3,183 | 0,050 | |

| Legend |

| vc = cutting speed [m/min] |

| f = feed (mm/r) |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | ||||||

| For dia. 12.5 | ||||||

| Material designation | Tensile strength | From dia. 12.5 | ||||

| vc | n | f | ||||

| from | to | from | to | |||

| Steels | ||||||

| General structural steels | ≤ 850 N/mm² | 25 | 37 | 796 | 955 | 0,250 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 796 | 955 | 0,250 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 796 | 955 | 0,250 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 700 | 796 | 0,200 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 700 | 796 | 0,200 |

| Alloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 20 | 319 | 509 | 0,156 |

| Nitriding steels | ≤ 1,000 N/mm² | 10 | 20 | 319 | 509 | 0,156 |

| Tool steels | ≤ 1,000 N/mm² | 10 | 20 | 319 | 509 | 0,156 |

| High-speed steels | ≤ 1,000 N/mm² | 10 | 20 | 319 | 509 | 0,156 |

| Cast metals | ||||||

| Cast iron | ≤ 350 HB | 22 | 31 | 891 | 1,019 | 0,313 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 22 | 31 | 700 | 796 | 0,313 |

| Non-ferrous metal | ||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 1,019 | 1,528 | 0,250 |

| Plastics | ||||||

| Plastics, thermosetting | 20 | 37 | 636 | 955 | 0,250 | |

| Plastics, thermoplastic | 20 | 37 | 636 | 955 | 0,250 | |

| Wood | ||||||

| Softwood | 25 | 37 | 796 | 955 | 0,250 | |

| Hardwood | ||||||

| Hardwood | 22 | 31 | 700 | 796 | 0,200 | |

| Cutting values | ||||||||||||

| For dia. 6.3-10.0 | ||||||||||||

| Material designation | Tensile strength | From dia. 6.3 | From dia. 8.0 | From dia. 10.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 25 | 37 | 1,642 | 1,971 | 0,163 | 1,294 | 1,552 | 0,208 | 1,035 | 1,242 | 0,260 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 1,642 | 1,971 | 0,163 | 1,294 | 1,552 | 0,208 | 1,035 | 1,242 | 0,260 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 1,642 | 1,971 | 0,163 | 1,294 | 1,552 | 0,208 | 1,035 | 1,242 | 0,260 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 1,446 | 1,642 | 0,130 | 1,138 | 1,294 | 0,163 | 910 | 1,035 | 0,208 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 1,446 | 1,642 | 0,130 | 1,138 | 1,294 | 0,163 | 910 | 1,035 | 0,208 |

| Alloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 20 | 657 | 1,050 | 0,104 | 517 | 828 | 0,130 | 413 | 662 | 0,163 |

| Nitriding steels | ≤ 1,000 N/mm² | 10 | 20 | 657 | 1,050 | 0,104 | 517 | 828 | 0,130 | 413 | 662 | 0,163 |

| Tool steels | ≤ 1,000 N/mm² | 10 | 20 | 657 | 1,050 | 0,104 | 517 | 828 | 0,130 | 413 | 662 | 0,163 |

| High-speed steels | ≤ 1,000 N/mm² | 10 | 20 | 657 | 1,050 | 0,104 | 517 | 828 | 0,130 | 413 | 662 | 0,163 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 22 | 31 | 1,840 | 2,102 | 0,208 | 1,448 | 1,655 | 0,260 | 1,158 | 1,325 | 0,325 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 22 | 31 | 1,446 | 1,642 | 0,208 | 1,138 | 1,294 | 0,260 | 910 | 1,035 | 0,325 |

| Non-ferrous metal | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 2,021 | 3,032 | 0,160 | 1,592 | 2,387 | 0,200 | 1,273 | 1,910 | 0,250 |

| Plastics | ||||||||||||

| Plastics, thermosetting | 20 | 37 | 1,314 | 1,971 | 0,163 | 1,035 | 1,552 | 0,208 | 828 | 1,242 | 0,260 | |

| Plastics, thermoplastic | 20 | 37 | 1,314 | 1,971 | 0,163 | 1,035 | 1,552 | 0,208 | 828 | 1,242 | 0,260 | |

| Wood | ||||||||||||

| Softwood | 25 | 37 | 1,642 | 1,971 | 0,163 | 1,294 | 1,552 | 0,208 | 1,035 | 1,242 | 0,260 | |

| Hardwood | ||||||||||||

| Hardwood | 22 | 31 | 1,446 | 1,642 | 0,130 | 1,138 | 1,294 | 0,163 | 910 | 1,035 | 0,208 | |

| Cutting values | ||||||||||||

| For dia. 3.15-5.0 | ||||||||||||

| Material designation | Tensile strength | From dia. 3.15 | From dia. 4.0 | From dia. 5.0 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | ≤ 850 N/mm² | 25 | 37 | 2,526 | 3,032 | 0,080 | 1,989 | 2,387 | 0,100 | 1,831 | 2,197 | 0,115 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 2,526 | 3,032 | 0,080 | 1,989 | 2,387 | 0,100 | 1,831 | 2,197 | 0,115 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 25 | 37 | 2,526 | 3,032 | 0,080 | 1,989 | 2,387 | 0,100 | 1,831 | 2,197 | 0,115 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 2,223 | 2,526 | 0,063 | 1,751 | 1,989 | 0,080 | 1,611 | 1,831 | 0,092 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 22 | 31 | 2,223 | 2,526 | 0,063 | 1,751 | 1,989 | 0,080 | 1,611 | 1,831 | 0,092 |

| Alloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 20 | 1,011 | 1,617 | 0,050 | 796 | 1,273 | 0,063 | 733 | 1,172 | 0,072 |

| Nitriding steels | ≤ 1,000 N/mm² | 10 | 20 | 1,011 | 1,617 | 0,050 | 796 | 1,273 | 0,063 | 733 | 1,172 | 0,072 |

| Tool steels | ≤ 1,000 N/mm² | 10 | 20 | 1,011 | 1,617 | 0,050 | 796 | 1,273 | 0,063 | 733 | 1,172 | 0,072 |

| High-speed steels | ≤ 1,000 N/mm² | 10 | 20 | 1,011 | 1,617 | 0,050 | 796 | 1,273 | 0,063 | 733 | 1,172 | 0,072 |

| Cast metals | ||||||||||||

| Cast iron | ≤ 350 HB | 22 | 31 | 2,829 | 3,234 | 0,100 | 2,228 | 2,546 | 0,125 | 2,050 | 2,343 | 0,144 |

| Spheroidal graphite and malleable iron | ≤ 350 HB | 22 | 31 | 2,223 | 2,526 | 0,100 | 1,751 | 1,989 | 0,125 | 1,611 | 1,831 | 0,144 |

| Non-ferrous metal | ||||||||||||

| Aluminium | ≤ 600 N/mm² | 40 | 60 | 4,042 | 6,063 | 0,100 | 3,183 | 4,775 | 0,125 | 2,546 | 3,820 | 0,125 |

| Plastics | ||||||||||||

| Plastics, thermosetting | 20 | 37 | 2,021 | 3,032 | 0,080 | 1,592 | 2,387 | 0,100 | 1,464 | 2,197 | 0,115 | |

| Plastics, thermoplastic | 20 | 37 | 2,021 | 3,032 | 0,080 | 1,592 | 2,387 | 0,100 | 1,464 | 2,197 | 0,115 | |

| Wood | ||||||||||||

| Softwood | 25 | 37 | 2,526 | 3,032 | 0,080 | 1,989 | 2,387 | 0,100 | 1,831 | 2,197 | 0,115 | |

| Hardwood | ||||||||||||

| Hardwood | 22 | 31 | 2,223 | 2,526 | 0,063 | 1,751 | 1,989 | 0,080 | 1,611 | 1,831 | 0,092 | |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!