HSS annular cutter

HSS core drill bit

CREDRL-MET-HSS-DRLDP50MM-D20MM

Art.-no. 0630940200

EAN 4050642953789

Register now and access more than 125,000 products

High performance and rapid drilling progress with a long service life

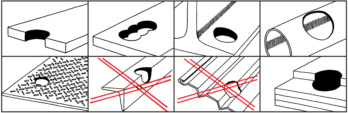

In contrast to solid drilling, only a thin metal ring is cut. The drill core is ejected by an ejector pin.

No pre-drilling required, no formation of burrs

No pre- or post-processing required

Optimised cutting geometry

- Long service life compared to many standard core drill bits

- Clean drill profile

- Drill hole with precise tolerances

Precise guidance, no slipping

Suitable for overlap drilling. Problem-free drilling on curved surfaces and pipes.

- Unlike twist drill bits, the annular cutter only machines a thin ring of material rather than the complete bore diameter. The drilling core is removed using a pilot pin with spring power, which is not included in the scope of delivery. Annular cutters therefore offer a drilling time that is 10 times faster than twist drills bits.

- Sufficient continuous cooling during the entire drilling process considerably increases the service life of the annular cutter. Do not use dry.

- Not suitable for press chipboard, titanium or heat-resistant and high-alloy steels

- For materials and cutting value parameters, see the summary overview tables

- Wear appropriate protective equipment, such as eye protection, hearing protection devices and protective gloves

- Take off loose clothing or jewellery which could get caught in the moving parts

- Annular cutters must not be used with hand-held tools

- Before use, ensure perfect concentricity and the correct clamping function of the tool drive

Datasheets(X)

- With Weldon shank ∅ 19 mm for use on mobile magnetic drills or stationary drills for creating large holes with a diameter of up to 50 mm and a cutting depth of 30 mm or 50 mm

- Fein drills with QuickIn mount can be used with an adapter

- Application on stationary drills with Morse taper is possible using the appropriate mount holder

- Insert the ejector pin into the core drill bit

- Push the core drill bit into the mount holder of the drill unit and tighten the hexagon socket screws

- The core drill bit is automatically locked into place when using quick-action mounts

- Make sure the core drill bit is sitting cleanly in the mount

- Putting the drill under lateral load during use may cause the tool to break

- Fix the drill unit into the right position for drilling — make sure the drill unit has a stable footing

- If necessary, secure the drill unit before drilling using a safety strap, especially for use on vertical surfaces and overhead work

- Pay attention to the speed table and use coolant

- Drill carefully (without centre punching and pre-drilling), pay attention to an even feed and even rotation speed throughout the entire drilling process

- Remove chips and drill core after each drilling operation

- Caution: Risk of injury, chips and drill core may be very hot and sharp

Quality | Würth-Standard |

Cutting depth | 50 mm |

Diameter | 20 mm |

Length | 84.6 mm |

Material to be processed | Steel, Aluminium, Wood |

Shank style | Weldon |

Surface | Plain |

Cutting material | HSS |

Service life (points system) | 2 of 4 points |

Drilling speed (point system) | 3 of 4 points |

Bore hole quality (point system) | 4 of 4 points |

Versatility (points system) | 2 of 4 points |

Drilling behaviour (point system) | 3 of 4 points |

| Cutting values | |||||||||

| For dia. 12.0-20.0 | |||||||||

| Material designation | Tensile strength | from dia. 12.0 | from dia. 16.0 | from dia. 20.0 | |||||

| vc | n | n | n | ||||||

| from | to | from | to | from | to | from | to | ||

| Steels | |||||||||

| General structural steels | ≤ 850 N/mm² | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 265 | 345 | 199 | 259 | 159 | 207 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 265 | 345 | 199 | 259 | 159 | 207 |

| Cast metals | |||||||||

| Cast iron | ≤ 240 HB | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Nodular graphite and malleable iron | ≤ 240 HB | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Non-ferrous metals | |||||||||

| Aluminium | ≤ 450 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium alloys | ≤ 450 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Wrought aluminium alloys | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Aluminium cast alloys <= 10 % Si | ≤ 600 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Magnesium alloys | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Low-alloy copper | ≤ 400 | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 |

| Short-chipping brass | ≤ 850 | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Long-chipping brass | ≤ 850 | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Short-chipping bronze | ≤ 850 | 15 | 20 | 398 | 531 | 298 | 398 | 239 | 318 |

| Plastics | |||||||||

| Thermosetting plastics | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 | |

| Thermoplastics | 20 | 25 | 531 | 663 | 398 | 497 | 318 | 398 | |

| Key |

| vc = cutting speed [m/min] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | |||||||||

| For dia. 36.0-50.0 | |||||||||

| Material designation | Tensile strength | from dia. 36.0 | from dia. 40.0 | from dia. 50.0 | |||||

| vc | n | n | n | ||||||

| from | to | from | to | from | to | from | to | ||

| Steels | |||||||||

| General structural steels | ≤ 850 N/mm² | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 88 | 115 | 80 | 103 | 64 | 83 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 88 | 115 | 80 | 103 | 64 | 83 |

| Cast metals | |||||||||

| Cast iron | ≤ 240 HB | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Nodular graphite and malleable iron | ≤ 240 HB | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Non-ferrous metals | |||||||||

| Aluminium | ≤ 450 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Aluminium alloys | ≤ 450 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Wrought aluminium alloys | ≤ 400 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Aluminium cast alloys <= 10 % Si | ≤ 600 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Magnesium alloys | ≤ 400 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Low-alloy copper | ≤ 400 | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 |

| Short-chipping brass | ≤ 850 | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Long-chipping brass | ≤ 850 | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Short-chipping bronze | ≤ 850 | 15 | 20 | 133 | 177 | 119 | 159 | 95 | 127 |

| Plastics | |||||||||

| Thermosetting plastics | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 | |

| Thermoplastics | 20 | 25 | 177 | 221 | 159 | 199 | 127 | 159 | |

| Cutting values | |||||||||

| For dia. 24.0-32.0 | |||||||||

| Material designation | Tensile strength | from dia. 24.0 | from dia. 28.0 | from dia. 32.0 | |||||

| vc | n | n | n | ||||||

| from | to | from | to | from | to | from | to | ||

| Steels | |||||||||

| General structural steels | ≤ 850 N/mm² | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Unalloyed heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Low-alloy heat-treated steels | ≤ 850 N/mm² | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Unalloyed heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 133 | 172 | 114 | 148 | 99 | 129 |

| Low-alloy heat-treated steels | ≤ 1,000 N/mm² | 10 | 13 | 133 | 172 | 114 | 148 | 99 | 129 |

| Cast metals | |||||||||

| Cast iron | ≤ 240 HB | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Nodular graphite and malleable iron | ≤ 240 HB | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Non-ferrous metals | |||||||||

| Aluminium | ≤ 450 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Aluminium alloys | ≤ 450 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Wrought aluminium alloys | ≤ 400 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Aluminium cast alloys <= 10 % Si | ≤ 600 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Magnesium alloys | ≤ 400 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Low-alloy copper | ≤ 400 | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 |

| Short-chipping brass | ≤ 850 | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Long-chipping brass | ≤ 850 | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Short-chipping bronze | ≤ 850 | 15 | 20 | 199 | 265 | 171 | 227 | 149 | 199 |

| Plastics | |||||||||

| Thermosetting plastics | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 | |

| Thermoplastics | 20 | 25 | 265 | 332 | 227 | 284 | 199 | 249 | |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!