HVAC wedge lock washer for high-strength structural bolting assemblies

Steel, znc flake, slvr, for high-strength fittings

WSH-WDGELOK-(ZFSHL)-HLK-16

Register now and access more than 125,000 products

Applied and tightened both under the screw head and under the nut

Secures the screw connection against loosening

As a result of the surface pressure caused by the pretension on the screw head or nut support, during the tightening process the external radial ribs embed themselves in the screw head or nut support as well as in the corresponding counter support (component) due to their higher surface hardness. The screw or nut can then only rotate over the inside wedge surfaces of the HVAC washers. The wedge pitch is always larger than the respective thread pitch, which prevents unwanted loosening of the connection

To ensure that the wedge lock washers have the desired locking effect, the hardness of the connecting components may not be harder than the wedge lock washers themselves and 44HRC

Instead of the regular washers, HVAC washers are used in high-strength fittings. These washers are made of hexagonal screws and nuts of strength class 10.9 in accordance with DIN EN 14399-4 or DIN EN 14399-8, which correspond to k class K1 according to DIN EN 14399-1 (see Chapter 4.5).

General construction permit no. Z-14.4-702

Datasheets(X)

- HVAC washers for steel construction, particularly for securing HV fittings in accordance with DIN EN 14399-4 and DIN EN 14399-8 (Shim HV fittings) of K1 class

- HVAC washers secure connections in the presence of static as well as quasi-static and fatigue-relevant (dynamic) stresses

- The pretensioning forces according to Table 1 of the Z-14.4-702 permit apply to the screw connections with HVAC washers

- For tightening torques for the application of the torque method or pre-tightening torques when using the combined process, refer to Table 1 of the Z-14.4-702 permit

- Caution - the tightening torques differ from the values of the torque method or combined method according to DASt directive 024

- The values of Table 21 of DIN EN 1090-2 apply to the necessary prevailing angles ϑ

| |

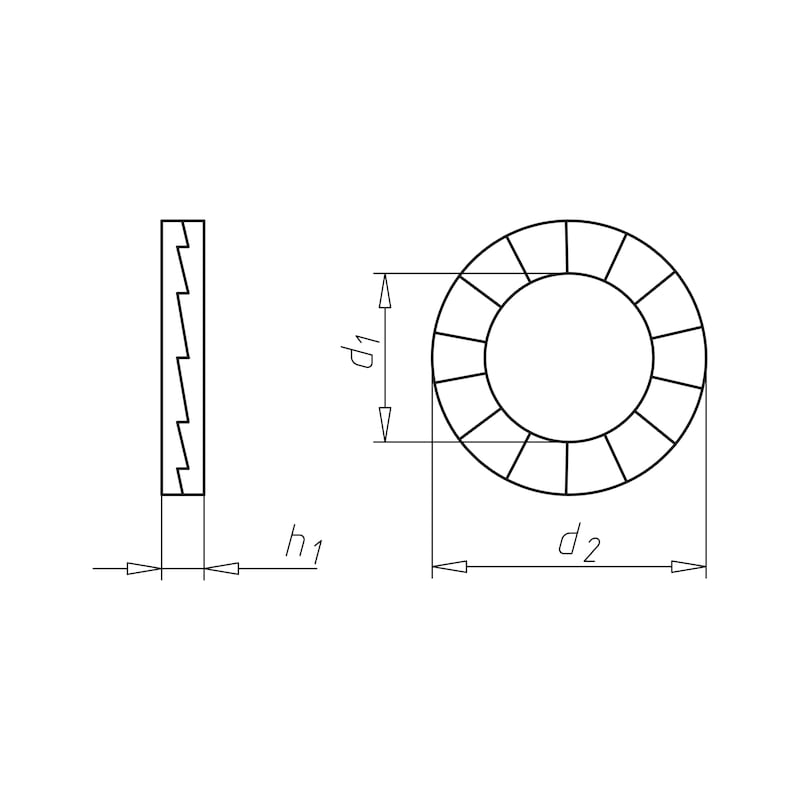

Internal diameter (d1) | 17 mm |

Suitable for screw thread | M16 |

Outer diameter (d2) | 30 mm |

Thickness (h1) | 3.7 mm |

Material | Steel |

Vickers hardness, HV | 485 HV |

Surface | Flake zinc silver |

Corrosion protection period | 600 h |

RoHS-compliant | Yes |

Area of application | Steel construction |

Locking function | Locking against self-loosening by mechanical interlocking |

Approval | DIBt Z-14.4-702 |