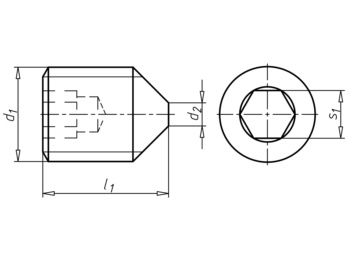

Hexagon socket set screw with flattened tip ISO 4027, steel 45H, zinc flake, silver (ZFSHL)

ISO 4027 steel 45H zinc flake

SCR-PT-ISO4027-45H-HS4-(ZFSHL)-M8X10

Register now and access more than 125,000 products

Zinc flake coatings are chrome (VI)-free corrosion protection coatings for commercial vehicle construction, construction machines, agricultural vehicles and equipment, and all other fields that require vehicle construction standard corrosion protection requirements.

The corrosion resistance of ZFHSL is as follows:

- Diameter ≥ M6 - 480h*

- Diameter ≥ M10 - 720h*

The designation ZFSHL refers to the following corrosion coating:

- Zinc flake coating, with top coat, silver colour, with lubrication that alters the friction coefficient.

- Adjusted friction coefficient range from 0.09μ - 0.14μ due to top coat with integrated lubricating particles

Hardness class 45H corresponds to a hardness of 450 HV

The standard tip has an angle of 90°, but very short lengths have an angle of 120°.

Steel set screws are intended for use under compressive stress only (see also DIN EN ISO 898-5). Typical uses include clamping in an adjusting ring or applying pressure to a counterpart. Steel set screws are therefore extremely hard in order to ensure torsional strength in the hexagon socket during tightening/loosening.

Tip:

A2/A4 stainless steel set screws are not specially hardened and may be used for tensile loads.

ISO 4027 replaces DIN 914 | There is some similarity | Nominal diameters for M1.4, M1.8, M14, M18, M22 are removed | Hardness classes for stainless steels introduced.

Datasheets(X)

| |

Thread type x nominal diameter (d1) | M8 |

Length (l1) | 10 mm |

Tip diameter (d2) | 2 mm |

Internal drive (s1) | HS4 |

Angle of the tip | 90 Degree |

Standards | ISO 4027 |

Material | Steel |

Hardness category | 45H |

Surface | Flake zinc silver |

Drive type | Hexagon socket |

Shape of tip | Tip |

RoHS-compliant | Yes |