Hexagon socket set screw with flattened tip ISO 4027, steel 45H, zinc-nickel-plated, black (ZNBHL)

ISO 4027 steel 45H zinc nickel black

SCR-PT-ISO4027-45H-HS2-(ZNBHL)-M4X8

Art.-no. 5125048

EAN 4046777163483

Register now and access more than 125,000 products

Connection elements with a galvanised chrome (VI)-free zinc-nickel coating (ZNBHL black or ZNSHL silver) are suitable for applications with a high risk of corrosion. The coating comprises a zinc-nickel alloy layer and a seal (top coat with integrated lubricating particles).

Overview of advantages:

- Corrosion resistance of up to 720 hrs to base metal corrosion in accordance with DIN EN ISO 9227 NSS

- Adjusted friction coefficient range from 0.09μ - 0.14μ due to top coat with integrated lubricating particles

- thermal capacity up to up to 120°C

- Even coat distribution

- Functional and decorative

Hardness class 45H corresponds to a hardness of 450 HV

The standard tip has an angle of 90°, but very short lengths have an angle of 120°.

Steel set screws are intended for use under compressive stress only (see also DIN EN ISO 898-5). Typical uses include clamping in an adjusting ring or applying pressure to a counterpart. Steel set screws are therefore extremely hard in order to ensure torsional strength in the hexagon socket during tightening/loosening.

Tip:

A2/A4 stainless steel set screws are not specially hardened and may be used for tensile loads.

ISO 4027 replaces DIN 914 | There is some similarity | Nominal diameters for M1.4, M1.8, M14, M18, M22 are removed | Hardness classes for stainless steels introduced.

Datasheets(X)

| |

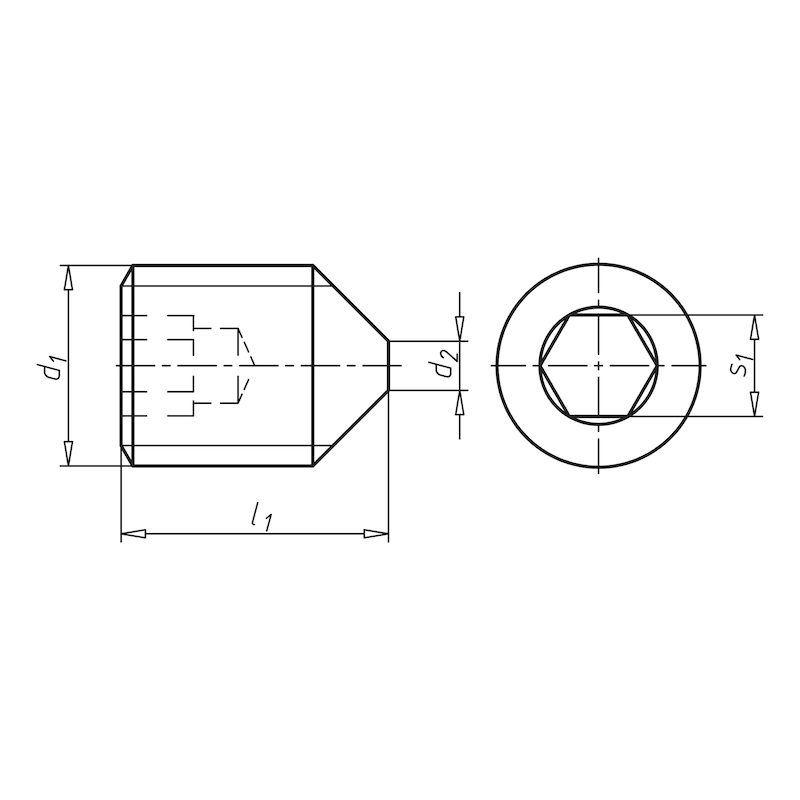

Thread type x nominal diameter (d1) | M4 |

Length (l1) | 8 mm |

Tip diameter (d2) | 1 mm |

Internal drive (s1) | HS2 |

Angle of the tip | 90 Degree |

Standards | ISO 4027 |

Material | Steel |

Hardness category | 45H |

Surface | Zinc nickel black |

Drive type | Hexagon socket |

Shape of tip | Tip |

RoHS-compliant | Yes |