Hot-melt edge adhesive pellets

Hot-melt edge adhesive granules

MLTADH-EDGE-GRANULATE-WHITE-25KG

Art.-no. 0892100034

EAN 4011231827560

Register now and access more than 125,000 products

Good running properties

- Low-viscosity adjustment

- Highly heat resistant

- Very good after-flow properties without threading

For universal use

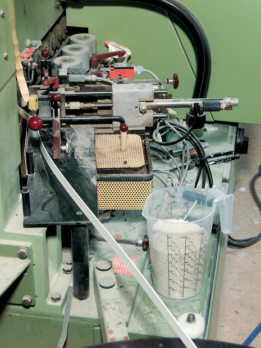

- For use on all commercially available edge bonding machines

- Rollers and slot nozzles available on request

Easy refills

Keeps joints moist.

Silicone-free

Hot-melt adhesives emit vapours even if the specified processing temperature is maintained. Unpleasant odours are often produced. If the prescribed processing temperatures are significantly exceeded over an extended period, there is also a risk of harmful decomposition products being produced. Measures must therefore be taken to eliminate vapours, e.g. by means of suitable extraction.

*Suitability depends on the specific properties of the edging material and the priming of it.

The usage instructions are recommendations based on the tests we have conducted and are based on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

Indoor edge gluing. Universal application for melamine resin, polyester*, ABS*, PVC* edges (* only with pre-primed edge material). Solid wood and veneer edges on chipboard, plywood, MDF boards, wood core plywood

Place the granules in the pre-melting container for the edge gluing machine and adjust the melting temperature and feed speed if necessary. The processing temperature should be between 190°C and 210°C. Note the contact pressure. The machine must be set in accordance with the machine manufacturer's instructions. In the event of prolonged work interruptions, the temperature should be decreased to 150-160°C to prevent the adhesive from burning. The pre-melting container should be cleaned at regular intervals. The carrier plate must be free from dust and grease. The temperature of the carrier plate and edge should be 18°C to 20°C. Avoid draughts. For edges with a thickness of above 4 mm, longer pre-heating is required to ensure the processing time. We always recommend conducting preliminary tests for laminate and solid wood panels. For more information, please refer to the technical data sheet.

Weight of content | 25 kg |

Chemical basis | Ethyl vinyl acetate |

Colour | White |

Density/conditions | 1.4 g/cm³ / at 20°C |

Viscosity | 65000 mPas |

Softening point | 90 °C |

Viscosity conditions | at 200°C |

Min./max. application quantity in assembly bonding | 250-350 g/m² |

Softening point/conditions | 90 °C / after ring and ball |

Min./max. processing temperature | 190 to 210 °C |

Min./max. optimum surface processing temperature | 18 to 20 °C |

Min./max. temperature resistance | -25 to +85 °C |

Min./max. feed speed | 15-50 m/min |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | at 15°C to 25°C |

Silicone-free | Yes |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!