Injectable mortar WIT-NORDIC

Chemical injection mortar WIT-NORDIC

ANC-MORT-(WIT-NORDIC)-CART-300ML

Register now and access more than 125,000 products

Two-part reactive resin mortar, styrene-free vinylester

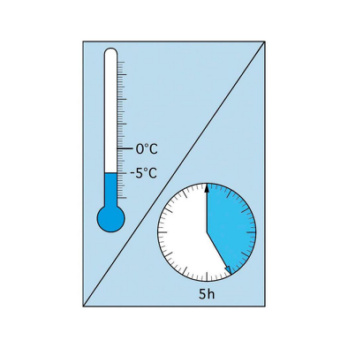

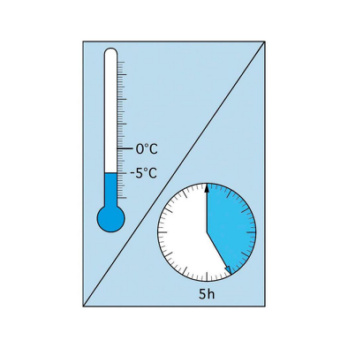

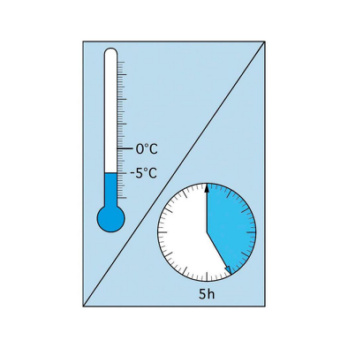

Ideal for construction sites in winter

- Can be used with an ambient and mortar temperature down to –20°C

- Cartridge and storage temperature above –20°C

Fixing point, cracked and non-cracked concrete, seismic performance category C1:

Anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1

Fixing point masonry:

Perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1

Cartridge can continue to be used until the best before date, by changing the mixer nozzle or resealing it with the end cap

- European Technical Assessment ETA-12/0164: Fixing point + cracked and non-cracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1

- European Technical Assessment ETA-16/0757: Fixing point + masonry (perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1)

Useful information: WIT-NORDIC is suitable for extremely low temperatures (cartridge, environment, base material) down to -20°C. Use at temperatures of +20°C or above (cartridge, environment, base material) is not recommended.

Post support bracket

Post support bracket

Illuminated advertising

Illuminated advertising

Satellite systems

Satellite systems

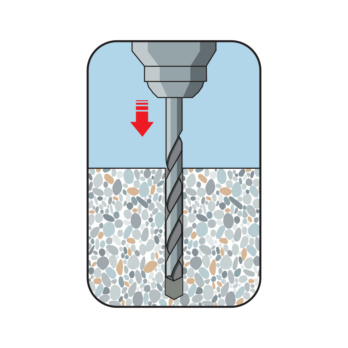

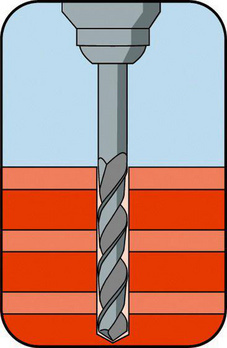

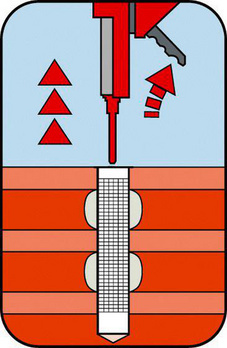

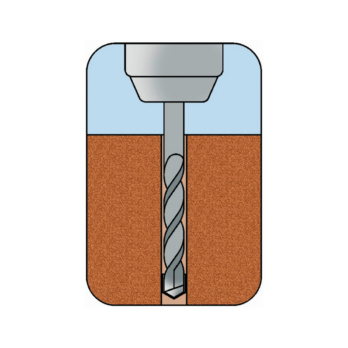

Create the drill hole

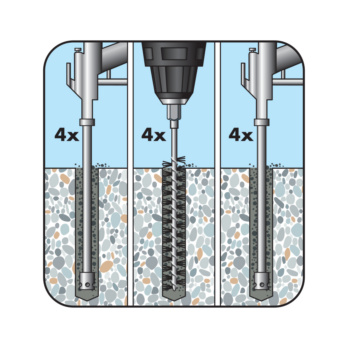

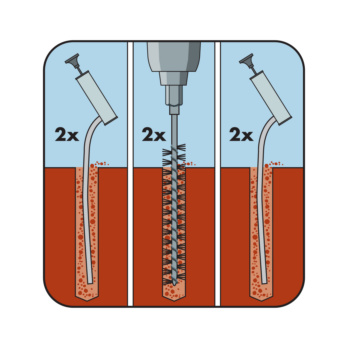

Clean the drill hole:

4x blow-out/4x mechanical brush-out/4x blow-out, effective anchorage depth > 240 mm drill hole with oil-free compressed air, min. 6 bar blow-out pressure

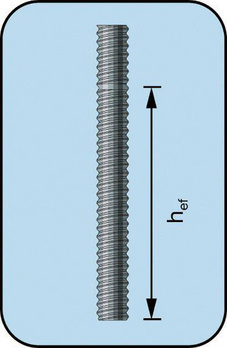

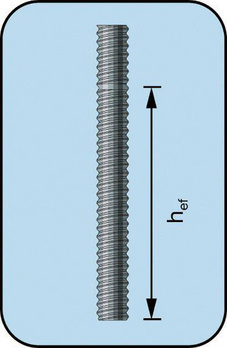

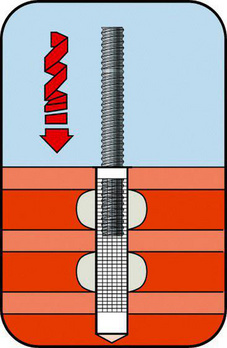

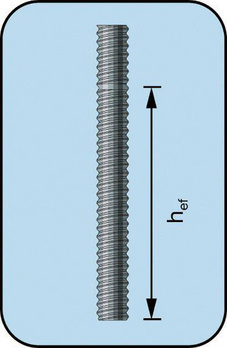

Cut anchor rod to length and mark the desired insertion depths

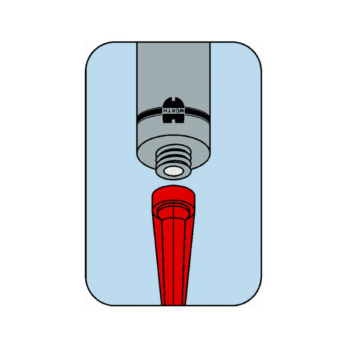

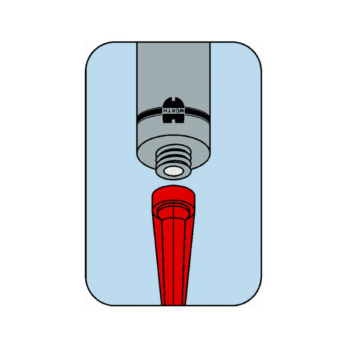

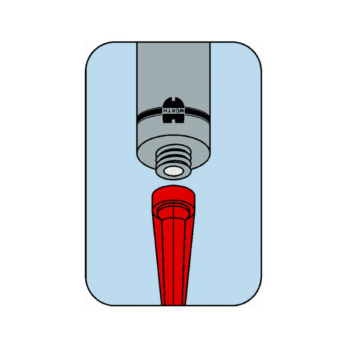

Screw mixer onto cartridge

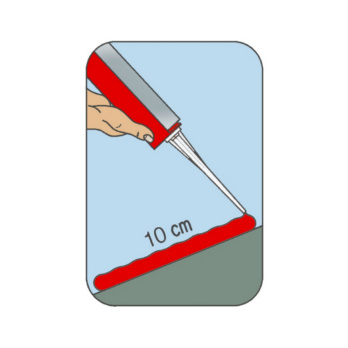

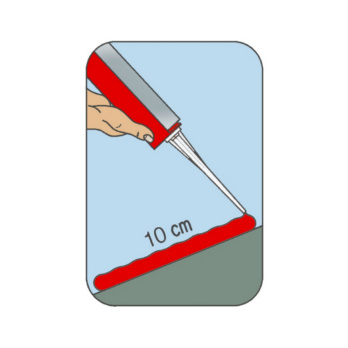

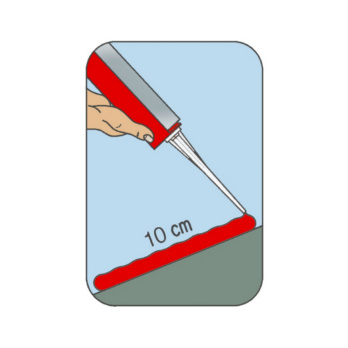

Before use, press out approx. 10 cm cord

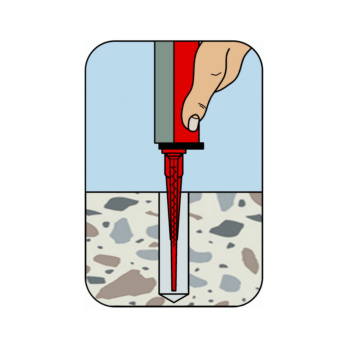

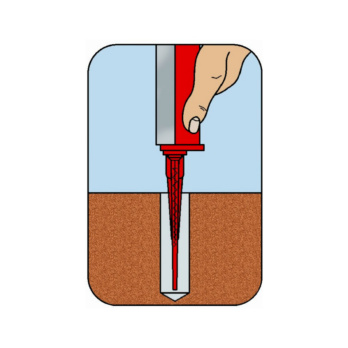

Fill composite mortar from bottom of drill hole

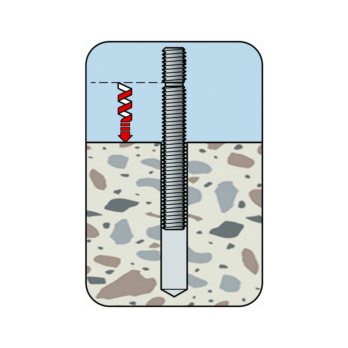

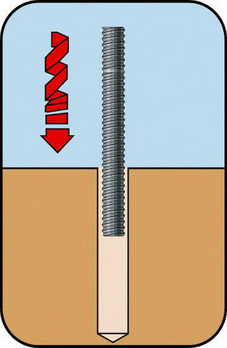

Press in anchoring element up to drill hole base while turning slightly

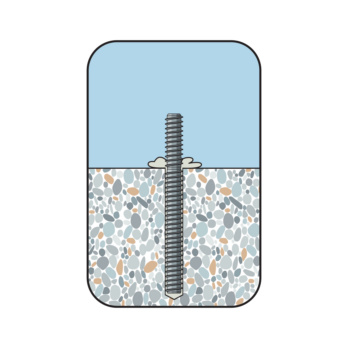

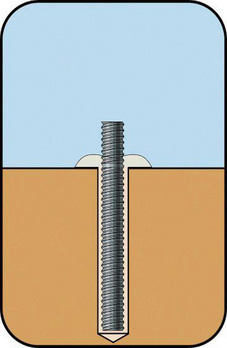

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

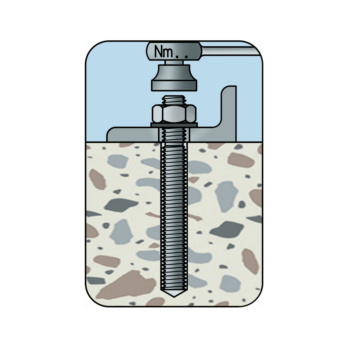

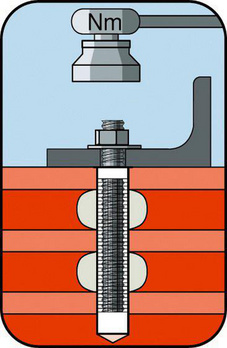

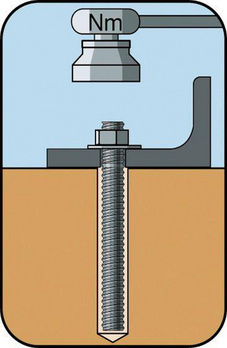

Install component, apply installation torque

Drill holes with a rotary drill (without impact mechanism)

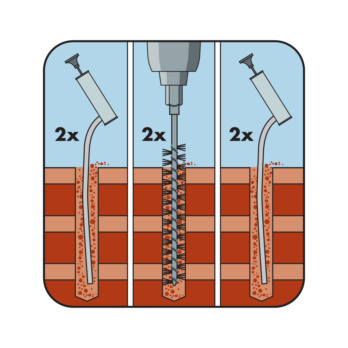

Clean the drill hole:

2x blow out/2x mechanical brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

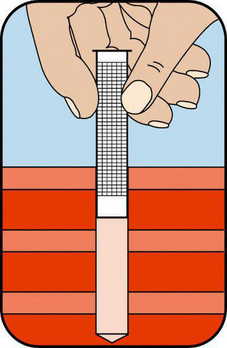

Insert perforated sleeve

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord

Completely fill with composite mortar from end of perforated sleeve

Press in anchor rod up to the bottom of the sleeve while turning slightly

Observe the injection mortar curing time

Mount component; do not exceed maximum torque

Create the drill hole

Clean the drill hole:

2x blow out/2x mechanical brush out/2x blow out

Cut anchor rod to length and mark the desired insertion depths

Screw mixer onto cartridge

Before use, press out approx. 10 cm cord

Fill with composite mortar starting from drill hole base (see enclosed leaflet)

Press in anchor rod up to the bottom of the sleeve while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the injection mortar curing time

Mount component; do not exceed maximum torque

- European Technical Assessment ETA-12/0164: Fixing point + cracked and non-cracked concrete (anchor rod W-VI-A, anchor rod W-VD-A, standard threaded rod with acceptance test certificate 3.1), seismic performance category C1

- European Technical Assessment ETA-16/0757: Fixing point + masonry (perforated sleeve SH, anchor rod W-VI-A, standard threaded rod with acceptance certificate 3.1)

- Anchorage at extremely low installation temperatures (down to -20°C)

- Suitable for fastening wooden structures, metal structures, metal profiles, brackets, grilles, sanitary ware, pipes, cable conduits etc.

Contents | 300 ml |

Suitable application gun | Battery-powered application gun 330ml |

Min./max. processing temperature /conditions | -20 to 10 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 120 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 72 °C |

Temperature resistance, short-term temperatures max. | 120 °C |

Shelf life from production/conditions | 12 Month / cool and dry storage area, 5°C to 25°C |

Approval | ETA-12/0164 |

Chemical basis | Vinylester, styrene free |

Colour | Grey |