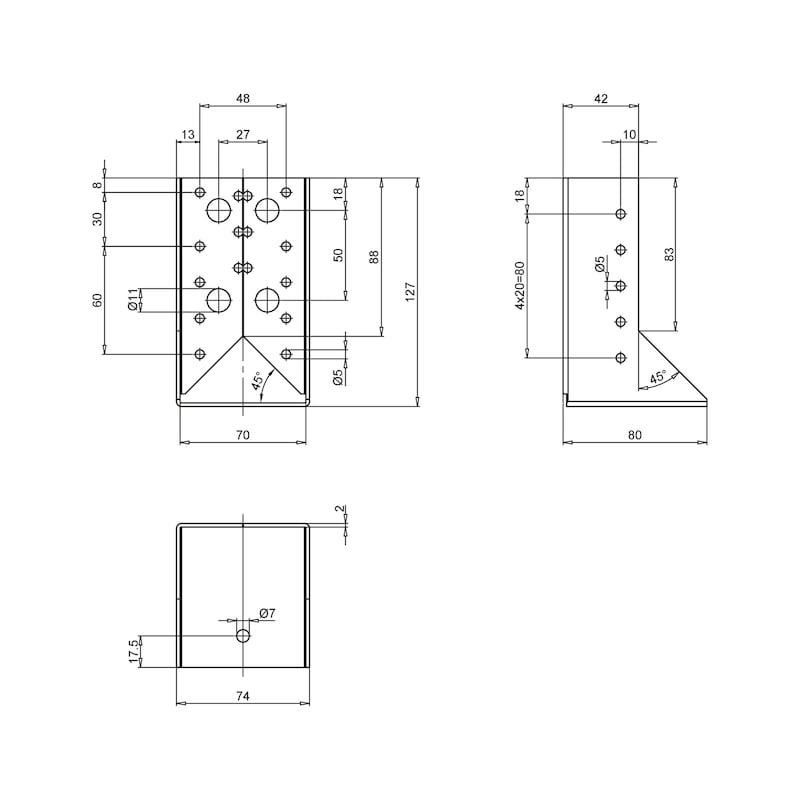

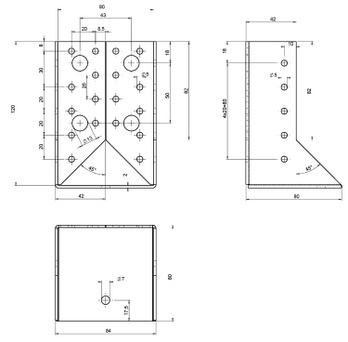

Joist hanger 2.0 mm One piece

Joist hanger one-part, angled inwards

JOISTHNG-(INTCRANKED)-80X120X2,0

Register now and access more than 125,000 products

- Beams under uniaxial load can be connected to posts of the same width

- Wings angled inwards

- Sheet metal hot-dip zinc-plated on both sides (S250GD +Z275), approx. 20 µm of thickness 2.0 mm in accordance with EN 10367:2004

- Application in utilisation class 1 and 2 in line with EN 1995:2013

European Technical Approval ETA–09/0021

Nail edge clearances in the post must be observed in line with EC5 when designing connections with biaxial loads!

The diameter of bolts/screws may only be max. 2 mm smaller than the diameter of the hole.

The respective basic conditions of the applicable anchor approval must be observed.

Available work documents:

Load tables and detailed processing instructions can be found on the service page www.wuerth.de/holzverbinder.

European Technical Approval ETA–09/0021

Subject to technical changes!

Load-bearing connections of timber joists to wood, concrete or steel in visible areas

Suitable fasteners:

- Ribbed nail in line with EN 14592: 4.0 x 40 to 100 mm.

- ASSY 3.0 Combi in line with ETA 11/0190: d = 10, 12 mm.

- Bolts according to manufacturers' specifications: d = 10, 12 mm.

- Recommended dowels for anchoring in concrete: W-BS; W-FAZ; W-VIZ; WIT-VM 250; WIT-UH 300

| |

Width x height | 80 x 120 mm |

Thickness | 2 mm |

Number of D 5 mm holes in subcarrier nJ + main carrier nH | 10 + 18 PCS |

Number of D 13 mm holes in subcarrier nJ/main carrier nH | 0 + 4 PCS |

Weight | 360 g |

Depth of underside | 80 mm |

Material | Steel |

Surface | Hot dip galvanized |

Width of wing on nut | 34 mm |

Approval | ETA-09/0021 |

Material designation | S250GD |

Material standard | DIN EN 10326:2004 |

Number of pieces | 1 PCS |

Depth of upper side | 42 mm |

| Partial and complete nailing of Würth joist hanger 2.0 mm with internal wings | |||||||||||||||

| Characteristic load-bearing capacities of Würth joist hangers 2.0 mm; internal wings with Würth comb/anchor nails | |||||||||||||||

| Art. no. | Format in mm | Complete nailing | Partial nailing | ||||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | ||||||||||

| 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | 4x40 | 4x60 | ||||

| 0681 089 120 | 80/120 | 16,0 | 24,5 | 9,4 | 15,2 | 6,2 | 9,5 | 7,8 | 12,1 | 6,7 | 10,6 | 3,7 | 5,7 | ||

| 0681 109 140 | 100/140 | 21,0 | 30,1 | 13,5 | 21.49 | 7,6 | 11,7 | 11,7 | 17,2 | 7,7 | 12,2 | 3,9 | 6,1 | ||

| 0681 110 160 | 120/160 | 27,3 | 38,7 | 19,5 | 30,5 | 10,0 | 15,3 | 13,4 | 20,1 | 12,5 | 17,2 | 5,2 | 8,0 | ||

| 0681 110 180 | 140/180 | 33,1 | 42,9 | 25,0 | 38,5 | 11,4 | 17,5 | 17,9 | 25,8 | 13,7 | 21,0 | 6,3 | 9,7 | ||

| Characteristic load-bearing capacities of Würth joist hangers 2.0 mm; internal wings with Würth ASSY 3.0 joist hanger screws | |||||||||||||||

| Art. no. | Format in mm | Complete screw connection | Partial screw connection | ||||||||||||

| Fz,down,Rk | Fz,up,Rk | Fy,Rk | Fz,down,Rk | Fz,up,Rk | Fy,Rk | ||||||||||

| 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | 5x40 | 5x50 | ||||

| 0681 089 120 | 80/120 | 25,6 | 28,0 | 21,3 | 23,4 | 12,1 | 13,9 | 16,2 | 18,7 | 12,8 | 14,0 | 7,3 | 8,3 | ||

| 0681 109 140 | 100/140 | 29,9 | 32,7 | 25,6 | 28,0 | 15,3 | 17,7 | 17,1 | 18,7 | 12,8 | 14,0 | 8,3 | 9,7 | ||

| 0681 110 160 | 120/160 | 38,4 | 42,1 | 34,1 | 37,4 | 19,7 | 22,7 | 21,3 | 23,4 | 17,1 | 18,7 | 10,6 | 12,3 | ||

| 0681 110 180 | 140/180 | 42,7 | 46,7 | 38,4 | 42,1 | 22,9 | 26,4 | 25,6 | 28,0 | 21,3 | 23,4 | 12,7 | 14,7 | ||

| Parameters of Würth joist hanger 2.0 mm; internal wings according to ETA-08/0021 | |||||||||||||||

| Art. no. | Format w/h (mm) | Width (mm) | Height (mm) | Complete nailing | Partial nailing | ||||||||||

| nH | nJ | kH,1 | kH,2 | e1 | e2 | nH | nJ | kH,1 | kH,2 | e1 | e2 | ||||

| [pcs] | [pcs] | mm | mm | [pcs] | [pcs] | mm | mm | ||||||||

| 0681 089 120 | 80/120 | 80 | 120 | 18 | 10 | 25,9 | 13,5 | 531 | 839 | 10 | 6 | 11,9 | 10,0 | 397 | 627 |

| 0681 109 140 | 100/140 | 100 | 140 | 22 | 12 | 34,8 | 19,7 | 864 | 1122 | 12 | 6 | 19,5 | 11,3 | 636 | 826 |

| 0681 110 160 | 120/160 | 120 | 160 | 26 | 16 | 47,5 | 29,7 | 2079 | 1973 | 14 | 8 | 22,1 | 20,0 | 1395 | 1324 |

| 0681 110 180 | 140/180 | 140 | 180 | 30 | 18 | 59,8 | 39,2 | 1879 | 2248 | 16 | 10 | 32,6 | 21,6 | 1262 | 1510 |

| Factor table for rated values | |||||||||||||||

| NKL | Continuously | Long | Medium | Short | Short/very short | Very short | |||||||||

| 1 | 0,462 | 0,538 | 0,615 | 0,692 | 0,769 | 0,846 | |||||||||

| 2 | 0,462 | 0,538 | 0,615 | 0,692 | 0,769 | 0,846 | |||||||||

| Notes: • Design according to ETA-09/0021 and DIN EN 1995-1-1 • The regulations and instructions of ETA-09/0021 must be observed. • The cross-reference must be checked separately. • The main support must be secured to prevent torsion These are guides for planning purposes. The values must be calculated for each project by authorised persons. | |||||||||||||||

| In the case of connections to main supports, all holes in the main support plate must be provided with screws or anchor nails; in the case of connections with partial nailing, only the holes marked in red. | |||||||||||||||

Datasheets (0)

Certificates/ Documents (0)

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!