Machine tap Speedtap 4.0-Ultra Hard Steel 63 HRC, straight grooved For metric ISO fine thread DIN 13

SC ST4.0 Ultra 63 HRC 6HX straight TiCN MF

MATAP-ST4.0-SC-HS-TICN-MF16X1,5

Art.-no. 5443711406

EAN 4062856188673

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

For throughhole and base thread. Particularly suitable for tough and difficult-to-machine materials as well as hard machining ≤ 63 HRC. Generation 4.0 sets new standards with threads.

Product information

Datasheets(X)

| |

Product code | 4655MF |

Thread type | Metric fine thread |

Material to be processed | Hard and tough material |

Hole type | Clearance/blind hole ≤ 1.5xD |

Thread type x nominal diameter | MF16 |

Pitch | 1.5 mm |

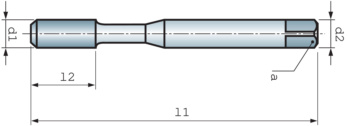

Length (l1) | 95 mm |

Thread length (l2) | 32 mm |

Shank diameter (d2) | 12 mm |

Size of square (a) | 9 mm |

Core hole diameter | 14.6 mm |

Number of teeth | 6 PCS |

Cutting material | SC |

Surface | TiCN |

Form | C |

Shank style | Cylindrical with square drive |

Tolerance of screw taps | ISO 2X (6HX) |

Tolerance of shank diameter | h9 |

Coolant supply | External |

Material of sub-group | Hardox, Steels > 45 HRC |

| Cutting values for Speedtap 4.0 thread tools | ||||||||||

| For MF8x1-MF12x1.5 | ||||||||||

| Material designation | Tensile strength | vc | MF8x1 | MF10x1 | MF12x1 | MF12x1.5 | ||||

| n | f | n | f | n | f | n | f | |||

| Steels | 42-54 HRC | 2,5 | 99 | 1 | 80 | 1 | 66 | 1 | 66 | 1,5 |

| Steels | 55-59 HRC | 2 | 80 | 1 | 64 | 1 | 53 | 1 | 53 | 1,5 |

| Steels | 60-63 HRC | 1,8 | 72 | 1 | 57 | 1 | 48 | 1 | 48 | 1,5 |

| Key | |

| vc = cutting speed [m/min] | |

| f = feed [mm/r] | |

| n = rotation speed [rpm] | |

| The suggested cutting values are reference values and must be adapted to the respective conditions. | |

| Cutting values for Speedtap 4.0 thread tools | ||||||||

| For MF14x1.5-MF20x1.5 | ||||||||

| Material designation | Tensile strength | vc | MF14 x 1.5 | MF16 x 1.5 | MF20 x 1.5 | |||

| n | f | n | f | n | f | |||

| Steels | 42-54 HRC | 2,5 | 57 | 1,5 | 50 | 1,5 | 40 | 1,5 |

| Steels | 55-59 HRC | 2,0 | 45 | 1,5 | 40 | 1,5 | 32 | 1,5 |

| Steels | 60-63 HRC | 1,8 | 41 | 1,5 | 36 | 1,5 | 29 | 1,5 |