Machine tap Speedtap 4.0-Uni/Inox, spiral-fluted For metric ISO fine thread DIN 13

HSS/PM ST4.0 Uni DIN 374 6HX spiral grooved HD

MATAP-GRNDHO-ST4-HSCOPM-UNI-HD-MF10X1,25

Art.-no. 5443711204

EAN 4062856188505

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 4619 |

Thread type | Metric fine thread |

Material to be processed | Steel, Cast metal, Stainless steel, Non-ferrous metal |

Hole type | Blind hole ≤ 3xD |

Thread type x nominal diameter | MF10 |

Pitch | 1.25 mm |

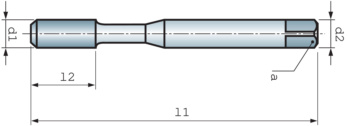

Length (l1) | 100 mm |

Thread length (l2) | 12 mm |

Shank diameter (d2) | 7 mm |

Size of square (a) | 5.5 mm |

Core hole diameter | 8.8 mm |

Number of teeth | 4 PCS |

Cutting material | HSCo-PM |

Standards | DIN 374 |

Surface | HARODUR |

Form | C |

Shank style | Cylindrical with square drive |

Tolerance of screw taps | ISO 2X (6HX) |

Tolerance of shank diameter | h9 |

Twist angle | 50° (right) |

Coolant supply | External |

Suitable for tensile strength up to | 1300 N/mm² |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Copper, Brass, Aluminium, Plastics |

| Cutting values for Speedtap 4.0 thread tools | ||||||||||||

| For MF8x1-M10x1.25 | ||||||||||||

| Material designation | Tensile strength | MF8x1 | MF10x1 | MF10x1.25 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | < 400 N/mm² | 15 | 26 | 597 | 1035 | 1 | 477 | 828 | 1 | 477 | 828 | 1,25 |

| Steels | < 850 N/mm² | 15 | 26 | 597 | 1035 | 1 | 477 | 828 | 1 | 477 | 828 | 1,25 |

| Steels | < 1100 N/mm² | 15 | 26 | 597 | 1035 | 1 | 477 | 828 | 1 | 477 | 828 | 1,25 |

| Steels | < 1300 N/mm² | 12 | 15 | 477 | 597 | 1 | 382 | 477 | 1 | 382 | 477 | 1,25 |

| Grey cast iron, malleable iron | 12 | 22 | 477 | 875 | 1 | 382 | 700 | 1 | 382 | 700 | 1,25 | |

| Stainless steels | < 850 N/mm² | 8 | 15 | 318 | 597 | 1 | 255 | 477 | 1 | 255 | 477 | 1,25 |

| Stainless steels | > 850 N/mm² | 8 | 15 | 318 | 597 | 1 | 255 | 477 | 1 | 255 | 477 | 1,25 |

| Titanium, titanium alloys | 3 | 5 | 119 | 199 | 1 | 95 | 159 | 1 | 95,0 | 159 | 1,25 | |

| Copper, brass | 8 | 15 | 318 | 597 | 1 | 255 | 477 | 1 | 255 | 477 | 1,25 | |

| Aluminium | 18 | 22 | 716 | 875 | 1 | 573 | 700 | 1 | 573 | 700 | 1,25 | |

| Plastics | 26 | 50 | 1035 | 1989 | 1 | 828 | 1592 | 1 | 828 | 1592 | 1,25 | |

| Key | |

| vc = cutting speed [m/min] | |

| f = feed [mm/r] | |

| n = rotation speed [rpm] | |

| The suggested cutting values are reference values and must be adapted to the respective conditions. | |

| Cutting values for Speedtap 4.0 thread tools | ||||||

| For MF20x1.5 | ||||||

| Material designation | Tensile strength | MF20x1.5 | ||||

| vc | n | f | ||||

| from | to | from | to | |||

| Steels | < 400 N/mm² | 15 | 26 | 239 | 414 | 1,5 |

| Steels | < 850 N/mm² | 15 | 26 | 239 | 414 | 1,5 |

| Steels | < 1100 N/mm² | 15 | 26 | 239 | 414 | 1,5 |

| Steels | < 1300 N/mm² | 12 | 15 | 191 | 239 | 1,5 |

| Grey cast iron, malleable iron | 12 | 22 | 191 | 350 | 1,5 | |

| Stainless steels | < 850 N/mm² | 8 | 15 | 127 | 239 | 1,5 |

| Stainless steels | > 850 N/mm² | 8 | 15 | 127 | 239 | 1,5 |

| Titanium, titanium alloys | 3 | 5 | 48 | 80 | 1,5 | |

| Copper, brass | 8 | 15 | 127 | 239 | 1,5 | |

| Aluminium | 18 | 22 | 286 | 350 | 1,5 | |

| Plastics | 26 | 50 | 414 | 796 | 1,5 | |

| Cutting values for Speedtap 4.0 thread tools | ||||||||||||

| For MF14x1.5-M18x1.5 | ||||||||||||

| Material designation | Tensile strength | MF14x1.5 | MF16x1.5 | MF18x1.5 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | < 400 N/mm² | 15 | 26 | 341 | 591 | 1,5 | 298 | 517 | 1,5 | 265 | 460 | 1,5 |

| Steels | < 850 N/mm² | 15 | 26 | 341 | 591 | 1,5 | 298 | 517 | 1,5 | 265 | 460 | 1,5 |

| Steels | < 1100 N/mm² | 15 | 26 | 341 | 591 | 1,5 | 298 | 517 | 1,5 | 265 | 460 | 1,5 |

| Steels | < 1300 N/mm² | 12 | 15 | 273 | 341 | 1,5 | 239 | 298 | 1,5 | 212 | 265 | 1,5 |

| Grey cast iron, malleable iron | 12 | 22 | 273 | 500 | 1,5 | 239 | 438 | 1,5 | 212 | 389 | 1,5 | |

| Stainless steels | < 850 N/mm² | 8 | 15 | 182 | 341 | 1,5 | 159 | 298 | 1,5 | 141 | 265 | 1,5 |

| Stainless steels | > 850 N/mm² | 8 | 15 | 182 | 341 | 1,5 | 159 | 298 | 1,5 | 141 | 265 | 1,5 |

| Titanium, titanium alloys | 3 | 5 | 69 | 114 | 1,5 | 60 | 100 | 1,5 | 53 | 89 | 1,5 | |

| Copper, brass | 8 | 15 | 182 | 341 | 1,5 | 159 | 298 | 1,5 | 141 | 265 | 1,5 | |

| Aluminium | 18 | 22 | 409 | 500 | 1,5 | 358 | 438 | 1,5 | 318 | 389 | 1,5 | |

| Plastics | 26 | 50 | 591 | 1137 | 1,5 | 517 | 995 | 1,5 | 460 | 884 | 1,5 | |

| Cutting values for Speedtap 4.0 thread tools | ||||||||||||

| For MF12x1-M12x1.5 | ||||||||||||

| Material designation | Tensile strength | MF12x1 | MF12x1.25 | MF12x1.5 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | < 400 N/mm² | 15 | 26 | 398 | 690 | 1 | 398 | 690 | 1,25 | 398 | 690 | 1,5 |

| Steels | < 850 N/mm² | 15 | 26 | 398 | 690 | 1 | 398 | 690 | 1,25 | 398 | 690 | 1,5 |

| Steels | < 1100 N/mm² | 15 | 26 | 398 | 690 | 1 | 398 | 690 | 1,25 | 398 | 690 | 1,5 |

| Steels | < 1300 N/mm² | 12 | 15 | 318 | 398 | 1 | 318 | 398 | 1,25 | 318 | 398 | 1,5 |

| Grey cast iron, malleable iron | 12 | 22 | 318 | 584 | 1 | 318 | 584 | 1,25 | 318 | 584 | 1,5 | |

| Stainless steels | < 850 N/mm² | 8 | 15 | 212 | 398 | 1 | 212 | 398 | 1,25 | 212 | 398 | 1,5 |

| Stainless steels | > 850 N/mm² | 8 | 15 | 212 | 398 | 1 | 212 | 398 | 1,25 | 212 | 398 | 1,5 |

| Titanium, titanium alloys | 3 | 5 | 80,00 | 133 | 1 | 80 | 133 | 1,25 | 80 | 133 | 1,5 | |

| Copper, brass | 8 | 15 | 212 | 398 | 1 | 212 | 398 | 1,25 | 212 | 398 | 1,5 | |

| Aluminium | 18 | 22 | 477 | 584 | 1 | 477 | 584 | 1,25 | 477 | 584 | 1,5 | |

| Plastics | 26 | 50 | 690 | 1326 | 1 | 690 | 1326 | 1,25 | 690 | 1326 | 1,5 | |