Screw tap assortment HSCo, multiple blind hole, M3-M12

Screw tap cass. HSCo multi blind hole, 14 pcs

MATAP-SORT-GRNDHO-HSCO-MULTI-(M3-M12)

Art.-no. 0658800001

EAN 4056807656885

Register now and access more than 125,000 products

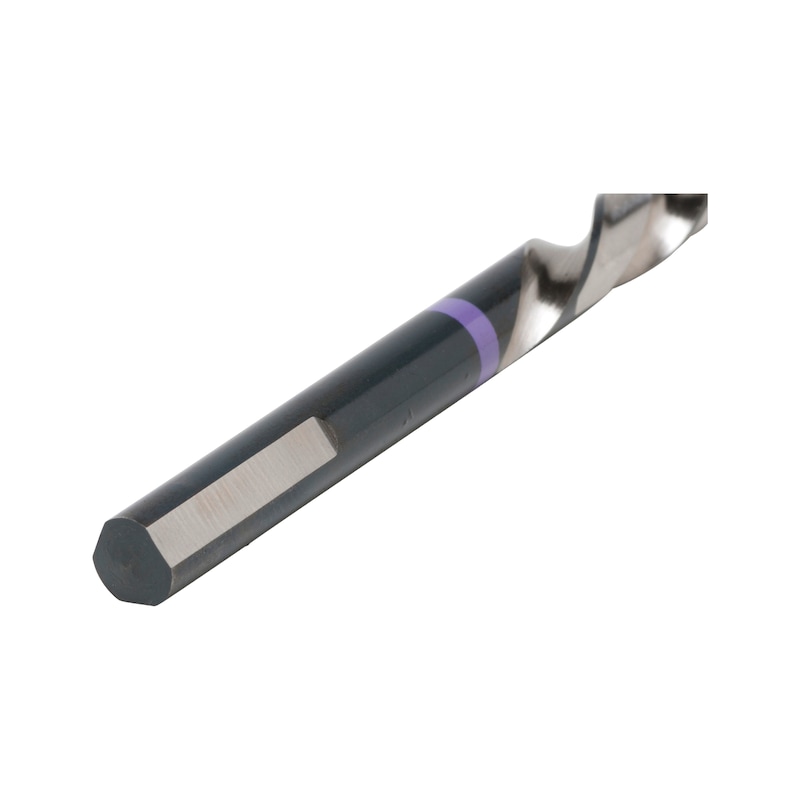

Twist drill bit

- Up to 50 % faster than conventionally ground twist drill bits due to its speed geometry

- 135° tip angle and optimised cross thinning for outstanding centring

- Exclusive vario coil

- Three-flat shank (from dia. 4 mm)

- Available exclusively from Würth

Machine thread former

- Flexible use in cordless drivers and hand-held, pillar and upright drills due to the additional polygon shank, which prevents slipping in the drill chuck.

- Suitable for conventional applications due to the retention of the straight shank with square mount

- Newly developed tool geometry with reduced chip angle as well as optimised clearance angle and microgeometry

- Up to three times longer service life than any other uncoated machine thread former from Würth

- Excellent chip removal, prevents chip accumulation at the tool's tip

- Available exclusively from Würth

- Sufficient coolant and lubricant must be added during drilling and thread cutting.

- For the tool/material assignments, see the overview tables.

- For further information, see the individual products.

Datasheets(X)

Number of pieces in assortment/set | 14 PCS |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Special alloy, Hard and tough material, Non-ferrous metal |

Quality | ZEBRA-Premium |

Hole type | Blind hole ≤ 2.5xD |

Cutting material | HSCo |

Surface | Vaporised |

Suitable for machine type | Drill, Cordless screwdrivers, Milling/drill center, Pedestal drilling machine |

Suitable for tensile strength up to | 1200 N/mm² |

Thread type | Metric thread |

Service life (points system) | 3 of 4 points |

Trueness to gauge (points system) | 4 of 4 points |

Versatility (points system) | 4 of 4 points |

Cutting behaviour (points system) | 4 of 4 points |

Chip formation (points system) | 3 of 4 points |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, sulphurated, Stainless steels, austenitic, Stainless steels, martensitic, Titanium, Titanium alloys, Special alloys, Hardox, Spring steels, Copper, low-alloyed, Bronze, long-chipping, Brass, long-chipping, Plastics, thermoset, Plastics, thermoplastic, Aluminium alloys, Aluminium, Aluminium casting alloys (<10% silicon), Aluminium wrought alloys |

| Key |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| n = rotation speed [rpm] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | ||||||||||||

| For M2-M3 | ||||||||||||

| Material designation | Tensile strength | M2 | M2.5 | M3 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 955 | 1273 | 0,40 | 764 | 1019 | 0,45 | 637 | 849 | 0,50 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 796 | 1273 | 0,40 | 637 | 1019 | 0,45 | 531 | 849 | 0,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 1273 | 1910 | 0,40 | 1019 | 1582 | 0,45 | 849 | 1273 | 0,50 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 318 | 477 | 0,40 | 255 | 382 | 0,45 | 212 | 318 | 0,50 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 1592 | 2387 | 0,40 | 1273 | 1910 | 0,45 | 1061 | 1592 | 0,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 2387 | 3183 | 0,40 | 1910 | 2547 | 0,45 | 1592 | 2122 | 0,50 |

| Thermosetting plastics | 4 | 6 | 637 | 955 | 0,40 | 509 | 764 | 0,45 | 424 | 637 | 0,50 | |

| Thermoplastic plastics | 4 | 6 | 637 | 955 | 0,40 | 509 | 764 | 0,45 | 424 | 637 | 0,50 | |

| For M24-M30 | |||||||||

| Material designation | Tensile strength | M24 | M30 | ||||||

| vc | n | f | n | f | |||||

| from | to | from | to | from | to | ||||

| Steels | |||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 80 | 106 | 3,00 | 64 | 85 | 3,50 |

| High-grade steels | |||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 66 | 106 | 3,00 | 53 | 85 | 3,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Cast metals | |||||||||

| Cast iron | < 300 HB | 10 | 15 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 106 | 159 | 3,00 | 85 | 127 | 3,50 |

| Hard materials | |||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 27 | 40 | 3,00 | 21 | 32 | 3,50 |

| Non-ferrous metals | |||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 133 | 199 | 3,00 | 106 | 159 | 3,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 199 | 265 | 3,00 | 159 | 212 | 3,50 |

| Thermosetting plastics | 4 | 6 | 53 | 80 | 3,00 | 42 | 64 | 3,50 | |

| Thermoplastic plastics | 4 | 6 | 53 | 80 | 3,00 | 42 | 64 | 3,50 | |

| For M14-M20 | ||||||||||||

| Material designation | Tensile strength | M14 | M16 | M20 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 136 | 182 | 2,00 | 119 | 159 | 2,00 | 95 | 127 | 2,50 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 114 | 182 | 2,00 | 99 | 159 | 2,00 | 80 | 127 | 2,50 |

| Titanium | < 850 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 182 | 273 | 2,00 | 159 | 239 | 2,00 | 127 | 191 | 2,50 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 45 | 68 | 2,00 | 40 | 60 | 2,00 | 32 | 48 | 2,50 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 227 | 341 | 2,00 | 199 | 298 | 2,00 | 159 | 239 | 2,50 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 341 | 455 | 2,00 | 298 | 398 | 2,00 | 239 | 318 | 2,50 |

| Thermosetting plastics | 4 | 6 | 91 | 136 | 2,00 | 80 | 119 | 2,00 | 64 | 95 | 2,50 | |

| Thermoplastic plastics | 4 | 6 | 91 | 136 | 2,00 | 80 | 119 | 2,00 | 64 | 95 | 2,50 | |

| For M8-M12 | ||||||||||||

| Material designation | Tensile strength | M8 | M10 | M12 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 239 | 318 | 1,25 | 191 | 255 | 1,50 | 159 | 212 | 1,75 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 199 | 318 | 1,25 | 159 | 255 | 1,50 | 133 | 212 | 1,75 |

| Titanium | < 850 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 318 | 477 | 1,25 | 255 | 382 | 1,50 | 212 | 318 | 1,75 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 80 | 119 | 1,25 | 64 | 95 | 1,50 | 53 | 80 | 1,75 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 398 | 597 | 1,25 | 318 | 477 | 1,50 | 265 | 398 | 1,75 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 597 | 796 | 1,25 | 477 | 637 | 1,50 | 398 | 531 | 1,75 |

| Thermosetting plastics | 4 | 6 | 159 | 239 | 1,25 | 127 | 191 | 1,50 | 106 | 159 | 1,75 | |

| Thermoplastic plastics | 4 | 6 | 159 | 239 | 1,25 | 127 | 191 | 1,50 | 106 | 159 | 1,75 | |

| For M4-M6 | ||||||||||||

| Material designation | Tensile strength | M4 | M5 | M6 | ||||||||

| vc | n | f | n | f | n | f | ||||||

| from | to | from | to | from | to | from | to | |||||

| Steels | ||||||||||||

| General structural steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Unalloyed quenched and tempered steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Low-alloy quenched and tempered steels | < 850 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Unalloyed quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Low-alloy quenched and tempered steels | < 1,000 N/mm² | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Alloyed quenched and tempered steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| Nitriding steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| Tool steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| High-speed steels | < 1,200 N/mm² | 6 | 8 | 477 | 637 | 0,70 | 382 | 509 | 0,80 | 318 | 424 | 1,00 |

| High-grade steels | ||||||||||||

| Stainless steels | < 1,200 N/mm² | 5 | 8 | 398 | 637 | 0,70 | 318 | 509 | 0,80 | 265 | 424 | 1,00 |

| Titanium | < 850 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Special alloys | < 1,200 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Cast metals | ||||||||||||

| Cast iron | < 300 HB | 10 | 15 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Spheroidal graphite and malleable iron | < 350 HB | 8 | 12 | 637 | 955 | 0,70 | 509 | 764 | 0,80 | 424 | 637 | 1,00 |

| Hard materials | ||||||||||||

| Hardox | < 1,400 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Spring steels | < 1,100 N/mm² | 2 | 3 | 159 | 239 | 0,70 | 127 | 191 | 0,80 | 106 | 159 | 1,00 |

| Non-ferrous metals | ||||||||||||

| Aluminium | < 450 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium alloys | < 450 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium wrought alloys | < 400 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Aluminium cast alloys <= 10 % Si | < 600 N/mm² | 15 | 20 | 796 | 1194 | 0,70 | 637 | 955 | 0,80 | 531 | 796 | 1,00 |

| Low-alloy copper | < 400 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Long-chipping brass | < 600 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Long-chipping bronze | < 1,000 N/mm² | 15 | 20 | 1194 | 1592 | 0,70 | 955 | 1273 | 0,80 | 796 | 1061 | 1,00 |

| Thermosetting plastics | 4 | 6 | 318 | 477 | 0,70 | 255 | 382 | 0,80 | 212 | 318 | 1,00 | |

| Thermoplastic plastics | 4 | 6 | 318 | 477 | 0,70 | 255 | 382 | 0,80 | 212 | 318 | 1,00 | |

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M3

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M4

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M5

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M6

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M8

MATAP-BLIHO-HSCO-DIN371-MULTI-PERFM-M10

MATAP-BLIHO-HSCO-DIN376-MULTI-PERFM-M12

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units