Mini cutter HSCo8 short, triple blade, centre-cutting

Mini end mill HSCo8 WN-K Z3 1.5xD 30° type N

CTR-SC-MINI-WN-S-HSCO8-D2,5MM

Art.-no. 5443600263

EAN 4055375874639

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 1246 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Copper, Brass, Plastic |

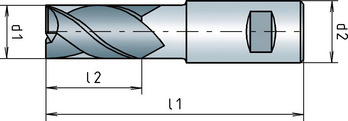

Diameter (d1) | 2.5 mm |

Shank diameter (d2) | 6 mm |

Length (l1) | 36 mm |

Cutting edge length (l2) | 5 mm |

Number of cutting edges (Z) | 3 PCS |

Standards | CS |

Construction length | Short |

Shank style | Cylindrical DIN 1835-B |

Cutting material | HSCo8 |

Surface | Plain |

Coolant supply | External |

Twist angle | 30° |

Tolerance of cutting edge diameter | e8 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Copper, Brass, Plastics |

| Cutting values for roughing contour | |||||||

| For dia. 1.5 to dia. 6 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 1.5 to dia. 1.9 | Dia. 2 to dia. 3.9 | Dia. 4 to dia. 5.9 | Dia. 6 | ||||

| General structural steels | < 500 N/mm² | E | 37 | 0,003 | 0,005 | 0,009 | 0,017 |

| 500-850 N/mm² | E | 30 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Carbon steels | < 850 N/mm² | E | 34 | 0,003 | 0,005 | 0,007 | 0,014 |

| 850-1000 N/mm² | E | 26 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 33 | 0,003 | 0,005 | 0,007 | 0,014 |

| 700-850 N/mm² | E | 30 | 0,003 | 0,005 | 0,007 | 0,014 | |

| 850-1000 N/mm² | E | 24 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 22 | 0,003 | 0,005 | 0,007 | 0,014 |

| 1000-1200 N/mm² | E | 18 | 0,003 | 0,005 | 0,009 | 0,017 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 30 | 0,003 | 0,005 | 0,007 | 0,014 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 22 | 0,003 | 0,005 | 0,007 | 0,014 |

| 1000-1200 N/mm² | E | 18 | 0,003 | 0,005 | 0,009 | 0,017 | |

| Nitriding steels | < 1000 N/mm² | E | 22 | 0,003 | 0,005 | 0,007 | 0,014 |

| 1000-1200 N/mm² | E | 18 | 0,003 | 0,005 | 0,009 | 0,017 | |

| Tool steels | < 850 N/mm² | E | 26 | 0,003 | 0,005 | 0,007 | 0,014 |

| 850-1100 N/mm² | E | 16 | 0,003 | 0,005 | 0,009 | 0,017 | |

| 1100-1400 N/mm² | E | 9 | 0,003 | 0,005 | 0,009 | 0,017 | |

| High-speed steels | 850-1200 N/mm² | E | 8 | 0,003 | 0,005 | 0,009 | 0,017 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 9 | 0,003 | 0,005 | 0,009 | 0,017 |

| Spring steels | < 1200 N/mm² | E | 8 | 0,003 | 0,005 | 0,009 | 0,017 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 24 | 0,003 | 0,005 | 0,007 | 0,014 |

| Stainless steels, austenitic | < 700 N/mm² | E | 18 | 0,003 | 0,005 | 0,007 | 0,014 |

| < 850 N/mm² | E | 12 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 9 | 0,003 | 0,005 | 0,009 | 0,017 |

| Cast iron | < 180 HB | - | 34 | 0,003 | 0,005 | 0,007 | 0,014 |

| > 180 HB | - | 30 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Nodular graphite, malleable iron | > 180 HB | - | 26 | 0,003 | 0,005 | 0,007 | 0,014 |

| > 260 HB | E | 18 | 0,003 | 0,005 | 0,007 | 0,014 | |

| Titanium, titanium alloys | < 850 N/mm² | E | 9 | 0,003 | 0,005 | 0,009 | 0,017 |

| Copper, low-alloy | < 350 N/mm² | E | 73 | 0,007 | 0,010 | 0,014 | 0,027 |

| Brass, short-chipping | < 600 N/mm² | - | 73 | 0,007 | 0,010 | 0,014 | 0,027 |

| Brass, long-chipping | < 600 N/mm² | - | 49 | 0,007 | 0,010 | 0,014 | 0,027 |

| Bronze, short-chipping | < 600 N/mm² | - | 49 | 0,007 | 0,010 | 0,014 | 0,027 |

| 650-850 N/mm² | - | 37 | 0,007 | 0,010 | 0,014 | 0,027 | |

| Bronze, long-chipping | < 850 N/mm² | E | 30 | 0,007 | 0,010 | 0,014 | 0,027 |

| 850-1200 N/mm² | E | 18 | 0,007 | 0,010 | 0,018 | 0,034 | |

| Legend | ||

| E = emulsion | ae = 0.1xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for finishing contour | |||||||

| For dia. 1.5 to dia. 6 | |||||||

| Material designation | Tensile strength | Cooling | vc | fz | |||

| Dia. 1.5 to dia. 1.9 | Dia. 2 to dia. 3.9 | Dia. 4 to dia. 5.9 | Dia. 6 | ||||

| General structural steels | < 500 N/mm² | E | 45 | 0,002 | 0,003 | 0,005 | 0,007 |

| 500-850 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Carbon steels | < 850 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| 850-1000 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| 700-850 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 | |

| 850-1000 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 |

| 1000-1200 N/mm² | E | 25 | 0,002 | 0,003 | 0,005 | 0,007 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 |

| 1000-1200 N/mm² | E | 25 | 0,002 | 0,003 | 0,005 | 0,007 | |

| Nitriding steels | < 1000 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 |

| 1000-1200 N/mm² | E | 25 | 0,002 | 0,003 | 0,005 | 0,007 | |

| Tool steels | < 850 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| 850-1100 N/mm² | E | 25 | 0,002 | 0,003 | 0,005 | 0,007 | |

| 1100-1400 N/mm² | E | 20 | 0,002 | 0,003 | 0,005 | 0,007 | |

| High-speed steels | 850-1200 N/mm² | E | 20 | 0,002 | 0,003 | 0,005 | 0,007 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 15 | 0,002 | 0,003 | 0,005 | 0,007 |

| Spring steels | < 1200 N/mm² | E | 15 | 0,002 | 0,003 | 0,005 | 0,007 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| Stainless steels, austenitic | < 700 N/mm² | E | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| < 850 N/mm² | E | 30 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 25 | 0,002 | 0,003 | 0,005 | 0,007 |

| Cast iron | < 180 HB | - | 38 | 0,002 | 0,003 | 0,004 | 0,006 |

| > 180 HB | - | 30 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Nodular graphite, malleable iron | > 180 HB | - | 30 | 0,002 | 0,003 | 0,004 | 0,006 |

| > 260 HB | E | 25 | 0,002 | 0,003 | 0,004 | 0,006 | |

| Titanium, titanium alloys | < 850 N/mm² | E | 20 | 0,002 | 0,003 | 0,005 | 0,007 |

| Copper, low-alloy | < 350 N/mm² | E | 120 | 0,004 | 0,006 | 0,008 | 0,011 |

| Brass, short-chipping | < 600 N/mm² | - | 100 | 0,004 | 0,006 | 0,008 | 0,011 |

| Brass, long-chipping | < 600 N/mm² | - | 100 | 0,004 | 0,006 | 0,008 | 0,011 |

| Bronze, short-chipping | < 600 N/mm² | - | 100 | 0,004 | 0,006 | 0,008 | 0,011 |

| 650-850 N/mm² | - | 80 | 0,004 | 0,006 | 0,008 | 0,011 | |

| Bronze, long-chipping | < 850 N/mm² | E | 80 | 0,004 | 0,006 | 0,008 | 0,011 |

| 850-1200 N/mm² | E | 65 | 0,004 | 0,006 | 0,011 | 0,014 | |

| Legend | ||

| E = emulsion | ae = 0.5xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||