Nail anchor W-NA/HCR with M6 thread

Nail anchor W-NA/HCR

ANC-(W-NA/HCR)-(HCR)-5-6X49

Art.-no. 0905382005

EAN 4053479287683

Register now and access more than 125,000 products

- Quick and easy installation

- Less drilling required thanks to reduced effective anchorage depth of 25 mm

- Easy insertion: Simply hammer in - no torque required

- No special drills or setting tools required

- Push-through installation

- Very low edge distances and spacings possible

- Torque-controlled expanding anchor — expands when subjected to load

- Multiple attachment of non-load-bearing systems in concrete: European Technical Approval ETA-11/0339

- Fire resistance: R30, R60, R90, R120 (anchoring base: concrete C20/25 to C50/60): Technical Report TR 020 "Evaluation of anchorages in concrete concerning resistance to fire" (included in ETA-11/0339)

- Fire-tested in line with the ZTV tunnel fire curve in the cracked tension zone

Not possible to order S-24!

The nail anchor offers the benefits of a bolt anchor while also being easy to install; the nail anchor is simply knocked into the drill hole through the attached part.

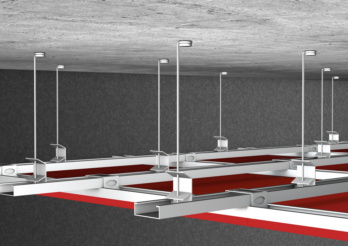

Suspended ceilings

Suspended ceilings

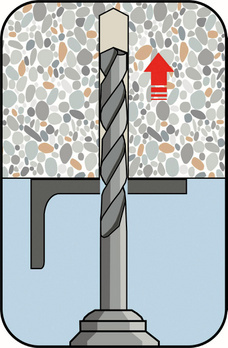

Create the drill hole

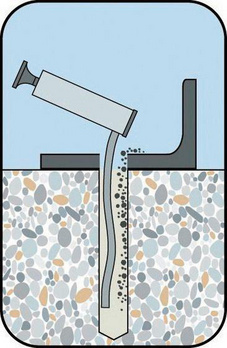

Clean the drill hole

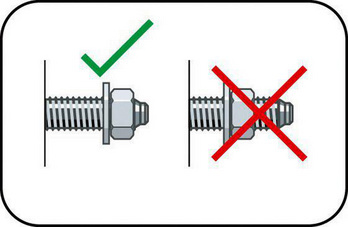

Check the position of the nut

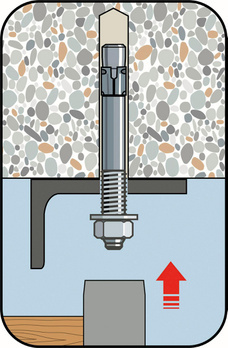

Insert W-NA through component and drive in

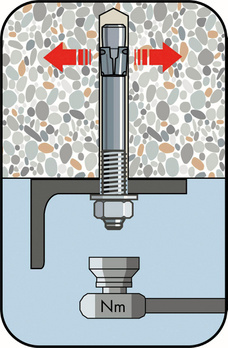

Apply torque Tinst ≤ 4 Nm

- Multiple attachment of non-load-bearing systems in concrete: European Technical Approval ETA-11/0339

- Fire resistance: R30, R60, R90, R120 (anchoring base: concrete C20/25 to C50/60): Technical Report TR 020 "Evaluation of anchorages in concrete concerning resistance to fire" (included in ETA-11/0339)

- Fire-tested in line with the ZTV tunnel fire curve in the cracked tension zone

Datasheets(X)

CAD data (available after login)

Anchors in a redundant non-structural system in non-load-bearing systems with approval in cracked concrete (tensile zone) and uncracked concrete (compression zone)

- E.g. lightweight ceiling cladding and suspended ceilings, pipes, cable trays, metal profiles, perforated strips, wire hangers, vernier hangers, wooden strips, wooden laths, square timbers etc.

- For use in reinforced or non-reinforced normal weight concrete with a concrete compressive strength of min. C12/15 and max. C50/60 in accordance with EN 206-1:2000-12

Can be used in areas where there is a very high risk of corrosion (e.g. indoor swimming pool atmospheres, road tunnels, poorly ventilated car parks, or with parts that are immersed in seawater or in coastal atmospheres)

Anchor diameter | 6 mm |

Anchor length (l) | 49 mm |

Min./max. height of the fixture (t fix) | 5-10 mm |

Nominal drill-bit diameter (d 0) | 6 mm |

Effective anchoring depth (h ef) | 30 mm |

Effective anchoring depth reduced (h ef, red) | 25 mm |

Drill hole depth (h 0) | 40 mm |

Drill hole depth reduced (h 0, red) | 35 mm |

Minimum component thickness (h min) | 80 mm |

Through-hole in the component to be connected (d f) | 7 mm |

Material | High corrosion-resistant steel, 1.4529, X1NiCrMoCuN25-20-7 |

Surface | Plain |

| Performance data | ||

| Anchor diameter [mm] | 6 (hef [mm] = 30) | |

| Anchors in concrete in a non-structural system based on a redundant design (for all load directions) for c ≥ 100 mm and s ≥ 200 mm | Fadm [kN] ≥ C12/15 | 1.93) |

| Fadm [kN] ≥ C20/25 and ≤ C50/601) | 2.83) | |

| Anchors in concrete in a non-structural system based on a redundant design (for all load directions) for c ≥ 50 mm and s ≥ 100 mm | Fadm [kN] ≥ C12/15 | 1,0 |

| Fadm [kN] ≥ C20/25 and ≤ C50/601) | 1,2 | |

| Adm. load under exposure to fire (Technical Report TR 020) for spacing and edge distances, see European Technical Assessment ETA-11/0039 | R30; Fadm [kN]2) | 0,9 |

| R60; Fadm [kN]2) | 0,9 | |

| R90; Fadm [kN]2) | 0,9 | |

| R120; Fadm [kN]2) | 0,7 | |

| Permissible bending moment | Madm [Nm] | 5,3 |

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For information on combining tensile and shear loads and the influence of the edge distance and anchor groups, please refer to the European Technical Approval Guidelines (ETAG), Appendix C. 2) The partial safety factors for load capacity when exposed to fire of γM,fi = 1.0, as recommended in the approval, and the partial safety factor of the actions of γF = 1.0 have been taken into account. 3) Number of attachment points ≥ 3 and at least one anchor per attachment point produces a load per attachment point of Fadm ≤ 1.4 kN or number of attachment points ≥ 4 and at least one anchor per attachment point produces a load per attachment point of Fadm ≤ 2.1 kN. The admissible loads can be increased if the design shows that the requirements governing the strength and stiffness of the component to be attached remain satisfied even after the failure of an anchor in terms of the limit state of serviceability and load capacity. | ||

| Characteristic values | ||

| Minimum member thickness | hmin [mm] | 80 |

| Effective anchorage depth | hef [mm] | 30 |

| Nominal drill ∅ | d0 [mm] | 6 |

| Diameter of cutting edges | dcut ≤ [mm] | 6,4 |

| Drill hole depth | h1 ≥ [mm] | 40 |

| Through hole in the component being connected | df ≤ [mm] | 7 |

| Torque while installing anchor | Tinst ≤ [Nm] | 4 |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!