Natural stone specialist injectable mortar WIT-EA 150 For natural stone

Inject. mortar natural stone specialist WIT-EA 150

ANC-MORT-(WIT-EA150)-CART-330ML

Register now and access more than 125,000 products

- 2-component reaction resin mortar, epoxy acrylate with styrene

- No staining when used in natural stone (a test should be performed beforehand on a stone sample to check whether the mortar compound causes discolouration)

- Cartridges can be used up to expiration of the best before date by replacing the mixer nozzle or by being closed again with sealing cap

Gates

Gates

Exterior lights

Exterior lights

TV wall brackets

TV wall brackets

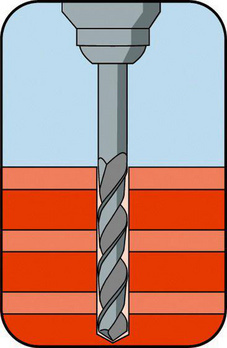

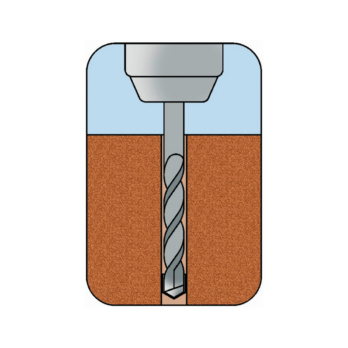

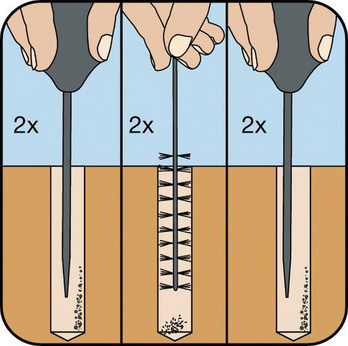

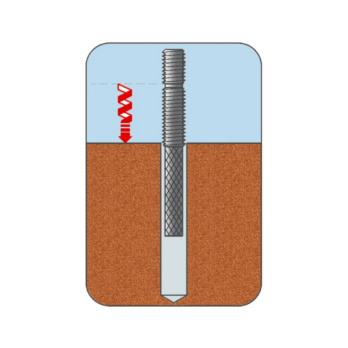

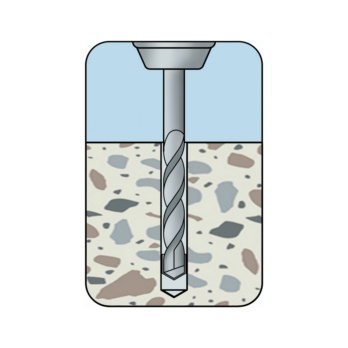

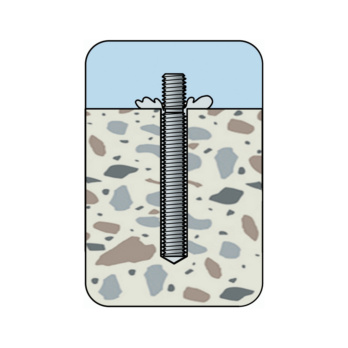

Drill holes with a rotary drill (without impact mechanism)

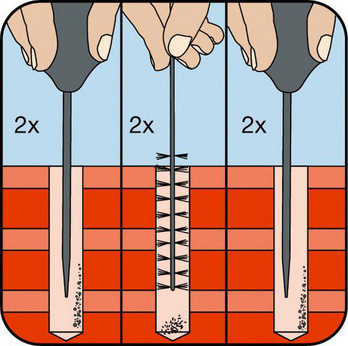

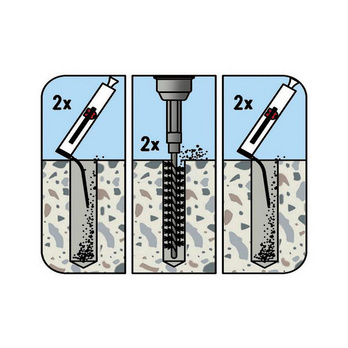

Clean drill hole; 2x blow out/2x brush out/2x blow out

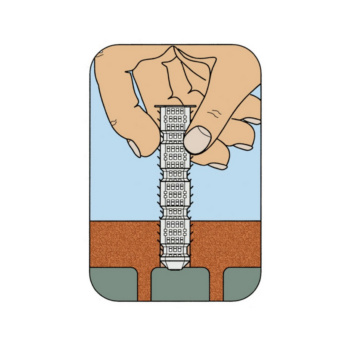

Insert perforated sleeve

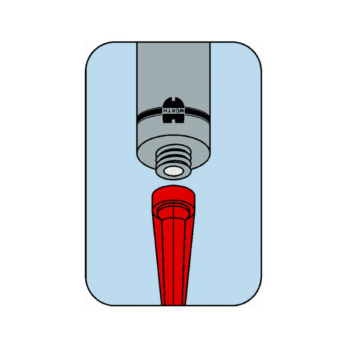

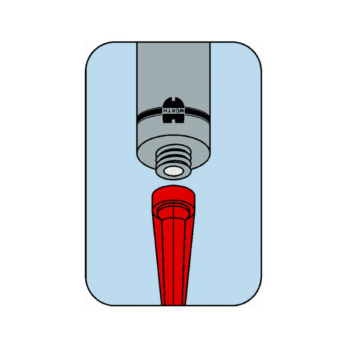

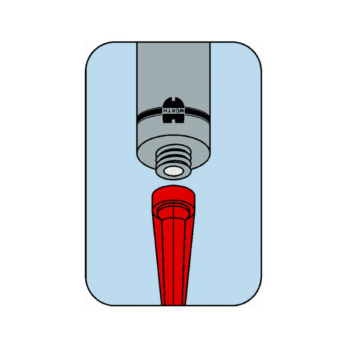

Screw mixer onto cartridge

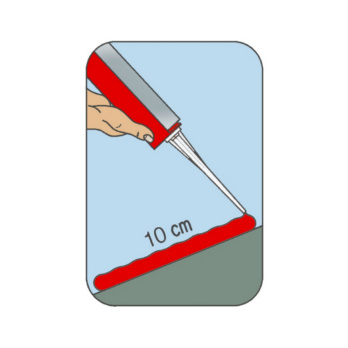

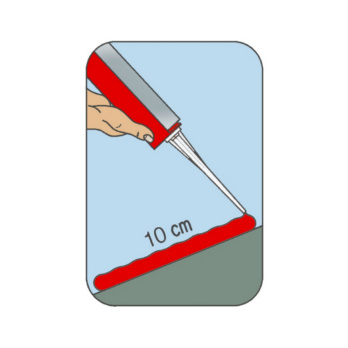

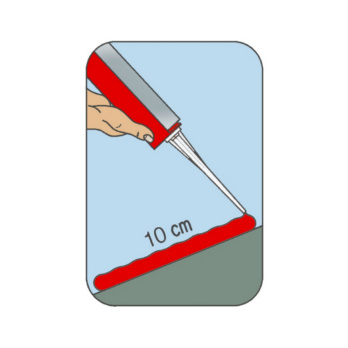

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

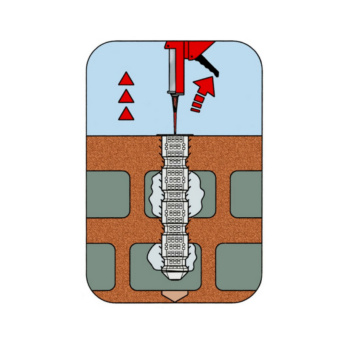

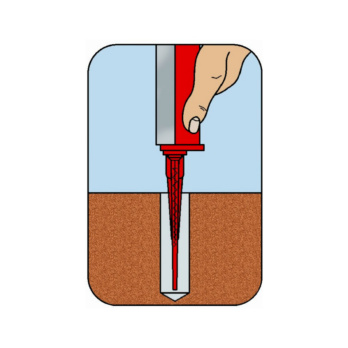

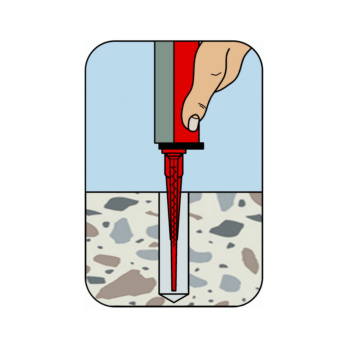

Completely fill with composite mortar from the end of the perforated sleeve (see enclosed leaflet)

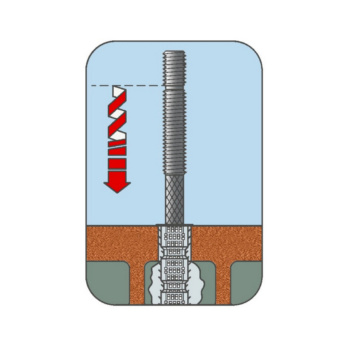

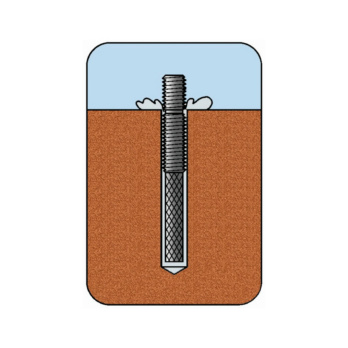

Press in the anchoring element up to the bottom of the sleeve while turning slightly

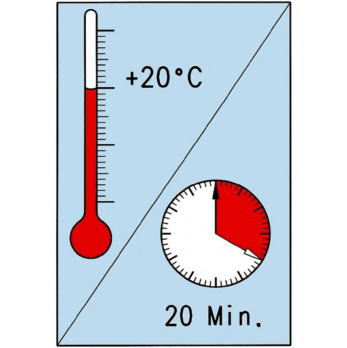

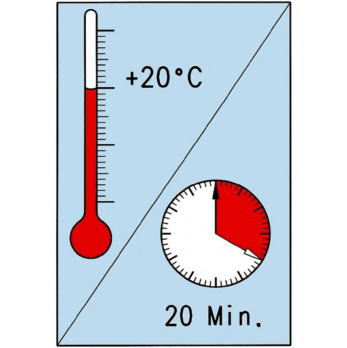

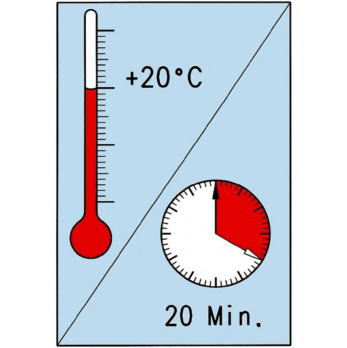

Observe the hardening time

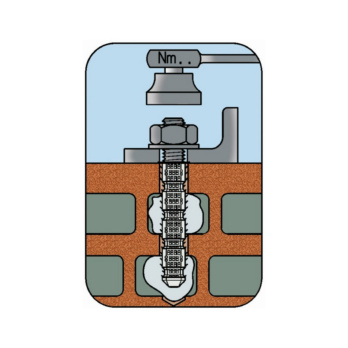

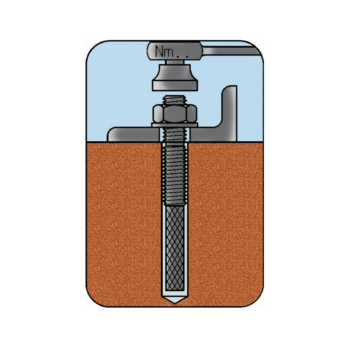

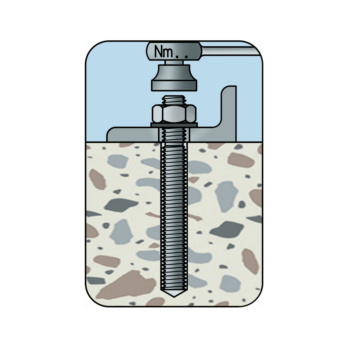

Mount the component; do not exceed the maximum torque

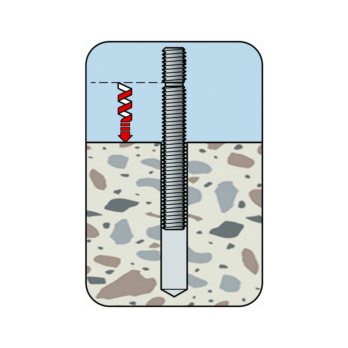

Create the drill hole

Clean drill hole; 2x blow out/2x brush out/2x blow out

Screw mixer onto cartridge

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Fill with composite mortar starting from the bottom of the drill hole (see enclosed leaflet)

Press in the anchoring element up to the bottom of the drill hole while turning slightly

Visual check of mortar volume, embedment depth mark

Observe the hardening time

Mount the component; do not exceed the maximum torque

Create the drill hole

Clean the drill hole

2x blow out, 2x mechanical brush out, 2x blow out

Blow out with compressed air from M20 drilled hole

Discard the first section of mortar (until the mortar is uniformly coloured - approx. 10 cm)

Fill composite mortar from bottom of drill hole

Press in anchoring element up to drill hole base while turning slightly

Visual check of mortar volume, embedment depth mark

Screw mixer onto cartridge

Mount the component. Do not exceed the maximum torque

Observe the hardening time

Natural stone (without approval):

- Anchor rod W-VD-A

- Anchor rod W-VI-A

- Or standard threaded rod with acceptance test certificate 3.1

Non-cracked concrete:

- Anchor rod W-VD-A

- Anchor rod W-VI-A

- Or standard threaded rod with acceptance test certificate 3.1

Masonry made of solid brick, (perforated brick) — without approval:

- Anchor rod WIT-AS

- Female thread sleeve WIT-IG

- Perforated sleeve WIT-SH

Type description | WIT-EA 150 |

Contents | 330 ml |

Included in delivery | Mortar cartridge 330 ml (coaxial) + 1 x mixer nozzle |

Suitable application gun | Battery-powered application gun 330ml, EasyMax 330 ml, Application gun MULTI, Application gun WIT 330ml, HandyMax 330 ml |

Min./max. processing temperature /conditions | -5 to 35 °C / temperature in the anchorage ground during processing and hardening |

Min./max. ambient temperature / Conditions | -40 to 80 °C / after completely curing process |

Temperature resistance, long-term temperatures max. | 50 °C |

Temperature resistance, short-term temperatures max. | 80 °C |

Shelf life from production/conditions | 18 Month / cool and dry storage area, 5°C to 25°C |

Chemical basis | Epoxy acrylate, with styrene |

Colour | Grey |

Certificates/ Documents (0)

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!