PU adhesive EURABOND RC GROUND

Adhesive EURABOND RC Ground

ASMBYADH-EURABOND-RC-GROUND-600ML

Art.-no. 0893710017

EAN 4062856626717

Register now and access more than 125,000 products

Suitable for the production of burglar-resistant windows and doors

- Tested according to RC resistance classes

- Also suitable for fixed glazing according to RC

- Collaboration with the leading profile system providers and fitting manufacturers

Broad applications

- Adapted to the insulating glass edge seal and laminated glass films

- Can be used for all frame materials

Saves time

- Reduces block setting

- Easy to handle, even on the construction site

High mechanical strength

Excellent creep resistance

Good resistance to humidity, weathering and extreme temperatures

Long skin formation time

Solvent and silicone-free

- To ensure that the bonded window system works correctly, these instructions for bonding, the processing guidelines of the system provider and the joint formation intended for the window structure must be observed.

- This product is not suitable for glass bonding where the adhesive surface is permanently exposed to UV.

- Stress cracking: PMMA, ABS, PC and PS must only be glued when they are not under tension, otherwise stress cracks are likely to occur. Preliminary testing is required.

- Avoid contact with substances that react with isocyanate (e.g. alcohol, thinners, cleaners, silane-modified polymer or silicone gap products) before the product is fully cured. These would prevent complete curing.

- Low temperatures lead to a temporarily higher viscosity and therefore lower discharge quantities and curing times.

- A key factor that affects the durability of the bond is the compatibility of the products in contact with each other. As incompatibilities may only arise over a long period of time, prior checks and compatibility tests are essential. RAL 716/1 section 3 can serve as a guideline for this. Unless otherwise specified, only materials approved by the system provider may be used for bonding.

Suitable for RC bonds in accordance with DIN EN 1627 – EURABON RC GROUND meets the requirements for glass bonding in accordance with DIN EN 1627

The usage instructions are recommendations based on the tests we have conducted and on our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting with deliberate intent. We guarantee the consistent quality of our products. We reserve the right to make technical changes and further develop products. Please observe the technical data sheet!

Datasheets(X)

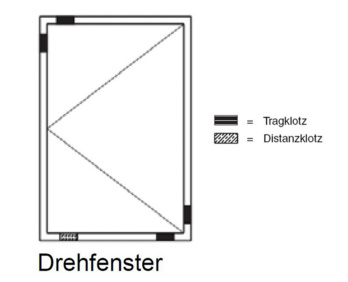

EURABOND RC GROUND is suitable for bonding in the production of burglar-resistant windows and doors according to RC resistance classes. The adhesive is particularly suitable for bonding the window rebate with the secondary seal of the insulating glass unit due to its mechanical properties and its composition, which is adapted to the insulating glass sealants.

The application surfaces must be clean, dry and free of grease. The IPA cleaner is best suited to PVC and wooden profiles. The acetone cleaner is only suitable for aluminium profiles. Optimal adhesion is achieved with the EURABOND activating cleaner PU. In the case of PVC profiles, EURABOND PRIMER PVC must then be applied abrasively to the parts to be bonded using the cleaning sponge.

To open the foil pouch, cut it directly below the lead seal. DIN ISO 5746 combination pliers are suitable for this purpose. To increase the application quantity, trim the tips to a length of approx. 5-6 cm. A flat tip shape allows insertion into the adhesive gap.

The adhesive must be applied using a suitable cordless or compressed-air gun to ensure a reliable finish.

For further information, please refer to the technical data sheet.

| |

Contents | 600 ml |

Container | Bag |

Chemical basis | Single component polyurethane |

Colour | Grey |

Density | 1.16 g/cm³ |

Full curing speed/conditions | 3 mm/d / 23°C and 50% relative humidity, moisture curing |

Shore hardness A/conditions | 55 / in accordance with DIN EN ISO 10563 |

Density/conditions | 1.16 g/cm³ / in accordance with DIN EN ISO 2811-1 |

Min. tensile strength | 4 N/mm² |

Min. combined tension and shear resistance | 3 N/mm² |

Conditions for tensile strength | in accordance with DIN 53571 |

Min. breaking elongation | 400 % |

Min./max. processing temperature | 5 to 35 °C |

Min./max. temperature resistance | -60 to 90 °C |

Max. change in volume | -6 % |

Max. volume change/conditions | -6 % / in accordance with DIN EN ISO 10563 |

Shelf life from production/conditions | 15 Month / at 5°C to 25°C |

Silicone-free | Yes |

Solvent-free | Yes |

Isocyanate-free | No |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!