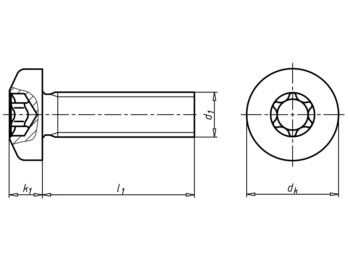

Pan Head screw with hexalobular head

ISO 14583 zinc flake steel 8.8, silver

SCR-ISO14583-8.8-TX30-(ZFSHL)-M6X10

Register now and access more than 125,000 products

Zinc flake coatings are chrome (VI)-free corrosion protection coatings for commercial vehicle construction, construction machines, agricultural vehicles and equipment, and all other fields that require vehicle construction standard corrosion protection requirements.

The corrosion resistance of ZFSHL is as follows:

- Diameter ≥ M6 – 480h*

- Diameter ≥ M10 – 720h*

The designation ZFSHL refers to the following corrosion coating:

- Zinc flake coating, with top coat, silver colour, with lubrication that alters the friction coefficient.

- Adjusted friction coefficient range from 0.09μ - 0.14μ due to top coat with integrated lubricating particles

Increase in assembly productivity

When elements are joined using hexalobular (TX) fasteners, the force is transmitted over a large surface area across the flanks of the drive rather than being centred on one point, as is the case with hexagon socket drives, for example. This has a number of advantages:

- Reduced tool wear

- Tool does not slip because force is distributed optimally

- No damage to surface coating

- No wobbling

- Screw locates securely

Hexalobular drives must comply with DIN EN ISO 10664

- As a result, connection elements with hexalobular heads are standardised and can be used all over the world

| |

Thread type x nominal diameter (d1) | M6 |

Length (l1) | 10 mm |

Head diameter (dk) | 12 mm |

Head height (k1) | 4.6 mm |

Standards | ISO 14583 |

Material | Steel |

Property class | 8.8 |

Surface | Flake zinc silver |

Corrosion protection period | 480 h |

RoHS-compliant | Yes |

Head type | Flat head |

Drive type | Internal hexalobular |

Internal drive | TX30 |

Thread type | Metric thread |

Pitch | 1 mm |

Thread form | Standard metric thread |

Product class | A |

Datasheets (0)

Certificates/ Documents (0)