Plastic frame anchor SHARK® UR A4 stainless steel

Plastic frame anchor SHARK UR stainless steel

ANC-SHARK-UR10-PLA-A4-AW40-45-10X115

ZEBRA

Register now and access more than 125,000 products

Anchor with universal options

- Part of the SHARK UR product family, which has been tested for more than 100 proven and modern building materials in total as part of ETA-08/0190

- The diameters 8 and 10 are tested and approved for a total of 105 different base materials

- Improved safety due to expert assessment on fire behaviour in concrete and masonry

High-quality material for optimal anchoring

- Due to the anchor geometry, the teeth expand in four directions and claw into the base material

- Anchorage via friction locking between anchor sleeve and base material

- High working loads due to expansion in four directions

- Improved load transmission due to even, continuous load transfer across the entire expansion area

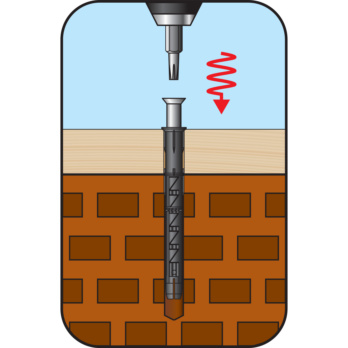

- Virtually no spinning of the anchor sleeve due to low installation torque and expansion

- Anchor sleeve made of high-quality polyamide

- Very strong anti-rotation lock

Quick installation

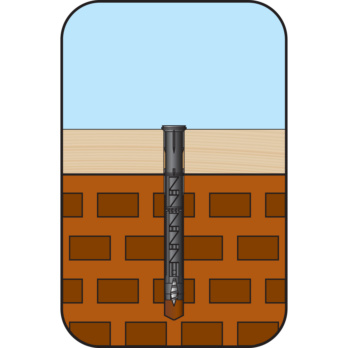

- Time-saving thanks to immediate load-bearing capacity

- Less installation work, because the anchor sleeve and special screw are pre-assembled

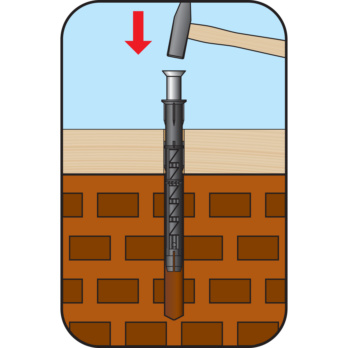

- Hammer-in stop prevents early expansion of the anchor during installation

Embedment depths

- Two embedment depths in defined building materials

- SHARK UR (zinc plated steel, stainless steel): European Technical Assessment ETA-08/0190

- Expert report on fire resistance period in the event of fire exposure

Wooden substructures

Wooden substructures

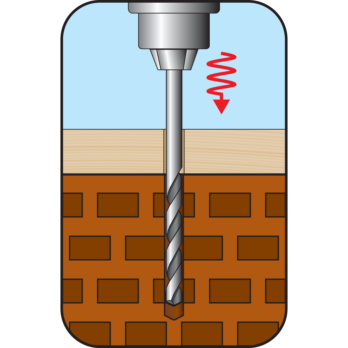

Drill the hole

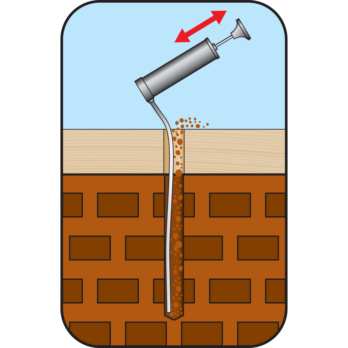

Remove drill cuttings

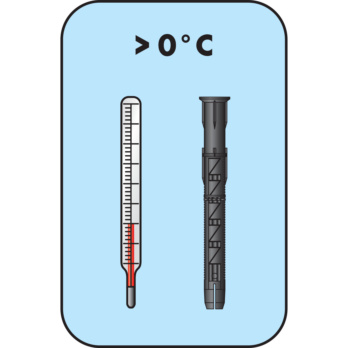

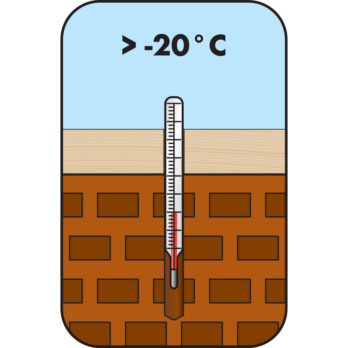

Check temperature of anchor sleeve

Check temperature of substrate

Install the anchor and screw with a hammer

Screw in dowel

Screw in screw until flush

- SHARK UR (zinc-plated steel, stainless steel): European Technical Assessment ETA-08/0190

- Expert report on fire resistance rating in the event of fire exposure

- The anchor can be used with a European technical assessment (ETA) for anchors in a redundant non-structural system in non-load-bearing systems (e.g. façades, suspended ceilings etc.)

- Approved by ETA assessment for over 100 building materials such as various bricks, including solid and perforated bricks, hollow sand-lime and solid blocks, solid concrete and perforated blocks, hollow concrete blocks made of lightweight concrete

- Suitable for normal weight concrete masonry walls such as solid brick, solid sand-lime blocks, vertically perforated brick, hollow sand-lime blocks, hollow lightweight concrete blocks, solid blocks and solid blocks made of lightweight concrete, bricks made of concrete and autoclaved aerated concrete

- Suitable for fastening façade, ceiling and roof substructures (made of wood or steel), wooden beams, wooden laths, metal brackets, metal rails, suspended ceilings, cable conduits, angle brackets, profiles, wall-mounted cabinets, racks etc.

- Suitable for outdoor and wet room applications due to the countersunk head screw made of A4 stainless steel

- Suitable for fastening, which requires proof of load-bearing capacity under fire load

- Drill perforated and hollow concrete blocks with a rotary drill (without hammer mechanism)

- Drill cuttings must be removed from the drill hole, e.g. with the blow-out pump art. no. 0903990001

- Drilling in concrete with a dust extraction drill bit means there is no need to clean the drill hole

- Installation temperature in base material ≥ -20 °C

- Installation temperature of the anchor sleeve ≥ 0 °C

Anchor diameter | 10 mm |

Anchor length (l) | 115 mm |

Max. attachment height (t fix) | 45 mm |

Nominal drill-bit diameter (d 0) | 10 mm |

Through-hole in the component to be connected (d f) | 10.5 mm |

Fire resistance rating | F30 |

Material of screw | Stainless steel A4 |

Internal drive | AW40 |

Surface of the screw | Plain |

Head type | Countersunk head |

Drill hole depth (h 1) | 80 mm |

Approval | ETA-08/0190 |

Type description | W-UR 10 A4, countersunk head screw |

| Mounting characteristic values for concrete and masonry for SHARK® UR 8 | ||

| Anchor diameter [mm] | SHARK® UR 8 | |

| Nominal drill ∅ | d0 [mm] | 8 |

| ∅ of cutting edges | dcut ≤ [mm] | 8,45 |

| Drill hole depth | h1 ≥ [mm] | 80 |

| Embedment depth of the anchor sleeve | hnom [mm] | 70 |

| Through hole in the attachment | df ≤ [mm] | 8,5 |

| Mounting characteristic values for concrete and masonry for SHARK® UR 10 | ||

| Anchor diameter [mm] | SHARK UR 10 | |

| Nom. drill ∅ | d0 [mm] | 10 |

| Drill cutting ∅ | dcut ≤ [mm] | 10,45 |

| Drill hole depth | h1 ≥ [mm] | 80 |

| Setting depth of the wall plug body | hnom [mm] | 70 |

| Through hole in attachment part | df ≤ [mm] | 10,5 |

| Masonry4): ETA-08/0190, multiple attachment of non-load-bearing systems (temperature range 50°C2)/80°C3)). For other types of stone, raw densities, minimum pressure strength or temperature ranges, please refer to the approval ETA-08/0190 | ||||

| Anchor diameter [mm] | Brick format [mm] | Raw density class [kg/dm3] | Minimum compressive strength [N/mm2] | Fperm [kN]5) (for single anchors or dowel group) SHARK UR 10 |

| Brick Mz, EN 771-1, DIN 105 | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.8 | 28 | 0,86 |

| 36 | 1,14 | |||

| Solid sand-lime brick KS, EN 771-2, DIN 106 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,43 |

| 20 | 0,71 | |||

| 28 | 1,0 | |||

| Plain concrete solid brick Vbn, EN771-3, DIN 18152 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | 0,57 |

| 20 | 0,86 | |||

| 28 | 1,29 | |||

| Vertically perforated brick HLz6), EN 771-1, DIN 105-1 e.g. Wienerberger, Schlagmann | ≥ 2DF (≥ 240 x 115 x 113) | ≥ 1.2 | 8 | 0,21 |

| 12 | 0,34 | |||

| 20 | 0,57 | |||

| Vertically perforated brick POROTON T8-306), EN 771-1, Z-17.1-982 Wienerberger, Schlagmann | ≥ 248 x 300 x 249 | ≥ 0.6 | 6 | 0,26 |

| Vertically perforated brick POROTON S11-36.56), EN 771-1, Z-17.1-812 Wienerberger, Schlagmann | ≥ 248 x 356 x 249 | ≥ 0.9 | 6 | 0,43 |

| Hollow sand-lime brick KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 2DF (≥ 240 x 115 x 113) | ≥ 1.6 | 10 | 0,43 |

| 12 | 0,57 | |||

| 16 | 0,71 | |||

| ≥ 8DF (≥ 249 x 240 x 238) | ≥ 1.4 | 10 | 0,34 | |

| 12 | 0,43 | |||

| 16 | 0,57 | |||

| Hollow block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | 0,09 |

| 4 | 0,17 | |||

| 6 | 0,26 | |||

| Hollow block made of lightweight concrete Liapor-Super-K6), EN 771-3, Z-17.1-501 | ≥ 16DF (≥ 495 x 240 x 238) | ≥ 0.8 | 2 | 0,17 |

| 4 | 0,34 | |||

| Aerated concrete AAC | 2 | 0,21 | ||

| 7 | 0,88 | |||

| 2) Maximum long-term temperature 3) Maximum short-term temperature 4) For other types of stone, raw densities, minimum compressive strength or temperature ranges, please refer to the approval ETA-08/0190 5) The stone geometry should be compared with the approval ETA-08/0190 6) If the drill hole is created through impact or hammer action, the admissible load must be determined by tests on the structure | ||||

| Concrete: ETA-08/0190, Anchors in a non-structural system based on a redundant design | ||||

| Anchor diameter [mm] | ||||

| Central tensile load1) for single anchors or dowel group | Nperm = C12/15 [kN] | 30°C2)/50°C3) | 1,0 | |

| 50°C2)/80°C3) | 1,0 | |||

| Nperm ≥ C16/20 [kN] | 30°C2)/50°C3) | 1,6 | ||

| 50°C2)/80°C3) | 1,4 | |||

| Transverse load1) for single anchors or dowel group | Vperm ≥ C12/15 [kN] | 5,37 | 4,99 | |

| Zinc-plated steel | ||||

| A4 stainless steel | ||||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the actions of γF = 1.4 have been taken into account. For the combination of tensile and shear loads, please refer to ETAG 020 Annex C 2) Maximum long-term temperature 3) Maximum short-term temperature | ||||

Datasheets (0)

Certificates/ Documents (0)