Plastic frame anchor W-UR 14 SymCon®

Plastic frame anchor, W-UR 14 SymCon cntrsnk. head

ANC-(W-UR SYM)-AW50-(A2K)-40-70-14X140

ZEBRA

Register now and access more than 125,000 products

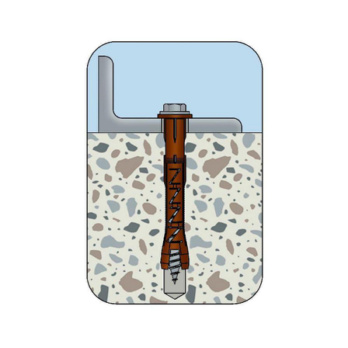

Virtually no spinning of the anchor sleeve

- Low installation torque of the screw

- "Slight" expansion of the anchor

Safe follow-up expansion capability

Enabled by the geometry of the SymCon screw

Increased load transfer

Screwing in the SymCon screw ensures optimal compression of the anchor sleeve plastic (virtually no undercutting)

Less installation work

Anchor sleeve and special screw are pre-assembled

European Technical Approval ETA-11/0309, multiple attachment of non-load-bearing systems in concrete and masonry

- For anchoring in solid brick and solid sand-lime brick, we recommend that you perform pull-out tests due to the differences in brick manufacturing

- Lengths 330 mm, 360 mm and 390 mm are not pre-assembled

- Drill perforated and hollow blocks in rotating gear (without impact mechanism)

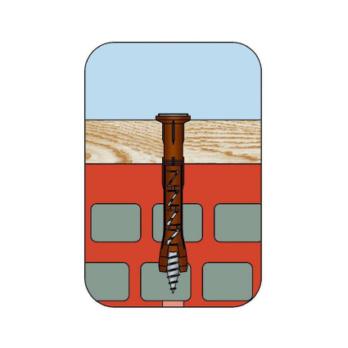

Metal substructures

Metal substructures

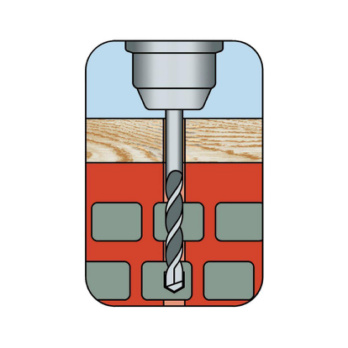

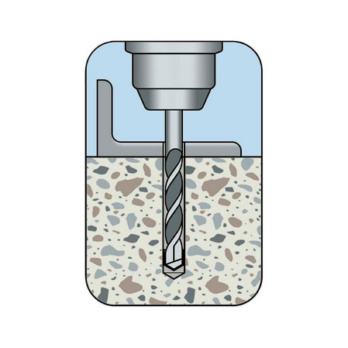

Create the drill hole

Create the drill hole

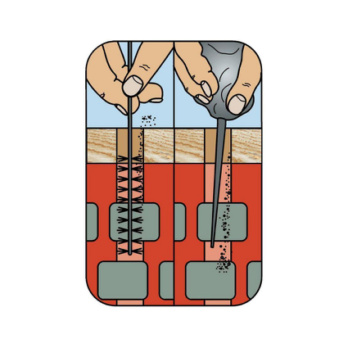

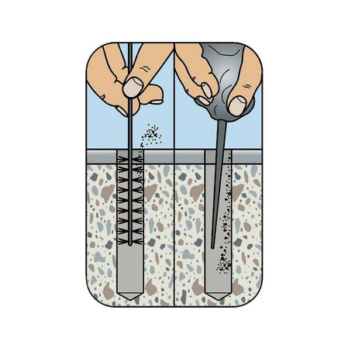

Clean the drill hole

Clean the drill hole

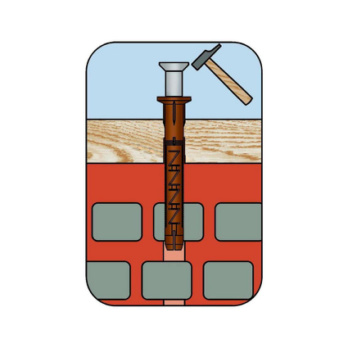

Set anchor and screw

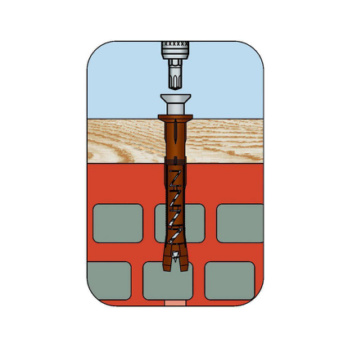

Screw in the screw

Screw in screw until flush

Create the drill hole

Create the drill hole

Clean the drill hole

Clean the drill hole

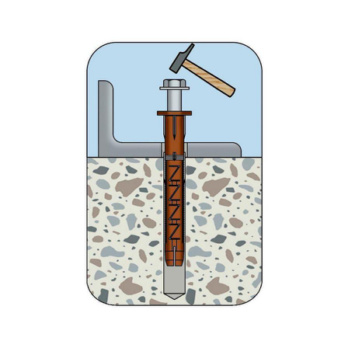

Set anchor and screw

Set anchor and screw

Screw in the screw

Screw in the screw

Screw in screw until flush

Screw in screw until flush

European Technical Approval ETA-11/0309, multiple attachment of non-load-bearing systems in concrete and masonry

Datasheets(X)

CAD data (available after login)

Multiple attachment of non-load-bearing systems with approval

e.g. façades, suspended ceilings, roof substructures (from wood or steel), wooden beams, wooden laths, angle brackets, wall-mounted cabinets, shelves etc.

Anchoring bases

- Standard concrete

- Masonry walls (solid brick, solid sand-lime brick, vertically perforated brick, hollow sand-lime brick, hollow lightweight concrete blocks, solid bricks and blocks made of lightweight concrete, concrete bricks)

Anchor diameter | 14 mm |

Anchor length (l) | 140 mm |

Nominal drill-bit diameter (d 0) | 14 mm |

Through-hole in the component to be connected (d f) | 14.5 mm |

Attachment height (t fix 1) | 70 mm |

Material of screw | Steel |

Internal drive | AW50 |

Surface of the screw | Zinc plated |

Approval | ETA-11/0309 |

Type description | W-UR 14 SymCon, countersunk head screw |

| 8 | - | 0,57 | |||

| 10 | - | 0,71 | |||

| Vertically perforated brick HLz T14-24.06), EN 771-1, Z-17.1-651 e.g. Wienerberger | ≥ 10DF (≥ 308 x 240 x 249) | ≥ 0.7 | 6 | - | 0,17 |

| Vertically perforated brick POROTON T8-306), POROTON T9-306), EN 771-1, T8: Z-17.1-982, T9: Z-17.1-674 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.6 | 6 | - | 0,43 |

| 8 | - | 0,57 | |||

| Vertically perforated brick POROTON S106), EN 771-1, Z-17.1-1017 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | - | 0,43 |

| Vertically perforated brick POROTON S11-306), EN 771-1, Z-17.1-812 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.9 | 8 | - | 0,71 |

| Vertically perforated brick ThermoPlan MZ106), EN 771-1, Z-17.1-1015 Mein Ziegelhaus | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | 0,57 | 0,71 |

| Vertically perforated brick ThermoPlan TS2) 6), EN 771-1, Z-17.1-993 Mein Ziegelhaus | ≥ 9DF (≥ 373 x 175 x 249) | ≥ 0.9 | 6 | - | 0,43 |

| 8 | - | 0,57 | |||

| 8 | - | 0,57 | |||

| Vertically perforated brick POROTON S106), EN 771-1, Z-17.1-1017 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | - | 0,43 |

| Vertically perforated brick POROTON S11-306), EN 771-1, Z-17.1-812 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.9 | 8 | - | 0,71 |

| Vertically perforated brick ThermoPlan MZ106), EN 771-1, Z-17.1-1015 Mein Ziegelhaus | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | 0,57 | 0,71 |

| Vertically perforated brick ThermoPlan TS2)6), EN 771-1, Z-17.1-993 Mein Ziegelhaus | ≥ 9DF (≥ 373 x 175 x 249) | ≥ 0.9 | 6 | 0,11 | 0,11 |

| 8 | 0,17 | 0,17 | |||

| 10 | 0,21 | 0,21 | |||

| 12 | 0,26 | 0,26 | |||

| 20 | 0,43 | 0,43 | |||

| Vertically perforated brick THERMOPOR TV 9-Plan6), EN 771-1, Z-17.1-1006 Thermopor Ziegel-Kontor Ulm | ≥ 247 x 300 x 249) | ≥ 0.75 | 4 | - | 0,26 |

| 6 | - | 0,43 | |||

| 8 | - | 0,57 | |||

| Hollow calcium silicate block KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 8DF (≥ 248 x 240 x 238) | ≥ 1.4 | 6 | - | 0,34 |

| 8 | - | 0,43 | |||

| 10 | - | 0,57 | |||

| 12 | - | 0,71 | |||

| Hollow concrete block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | - | 0,14 |

| 4 | - | 0,26 | |||

| 6 | - | 0,43 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and transverse loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) For other types of brick, raw densities, minimum compressive strength or temperature ranges, please refer to the approval ETA-11/0309. 5) The brick geometry should be compared with the approval ETA-11/0309. 6) If the drill hole is created through impact or hammer action, the permissible load must be determined by tests on the structure. | |||||

| Minimum member thickness | hmin | [mm] | 110 | 140 |

| Minimum axis distance4) | smin [mm] | C12/15 | 85 | 85 |

| ≥ C16/20 | 60 | 60 | ||

| Minimum edge distance4) | cmin [mm] | C12/15 | 115 | 115 |

| ≥ C16/20 | 80 | 80 | ||

| Characteristic edge distance | ccr,N [mm] | C12/15 | 110 | 140 |

| ≥ C16/20 | 80 | 100 | ||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and transverse loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) The permissible load must be reduced. | ||||

| 270 | 200/170 |

| 300 | 230/200 |

| 330 | 260/230 |

| 360 | 290/260 |

| 390 | 320/290 |

| Normal weight concrete solid brick Vbn, EN771-3, DIN 18153 | ≥ NF (≥ 240 x 115 x 71) | ≥ 2.0 | 10 | - | 0,57 |

| 20 | - | 0,86 | |||

| 28 | - | 1,14 | |||

| Normal weight concrete solid brick V, EN 771-3, DIN 18152-100 e.g. BisoBims Classic, Bisotherm | ≥ 3DF (≥ 240 x 115 x 113) | ≥ 2.0 | 10 | - | 1,14 |

| 20 | - | 1,57 | |||

| Lightweight concrete solid brick V, EN 771-3, DIN 18152-100 e.g. BisoBims | ≥ NF (≥ 240 x 115 x 71) | ≥ 1.0 | 2 | - | 0,34 |

| 4 | - | 0,57 | |||

| Vertically perforated brick HLz6), EN 771-1, DIN 105 e.g. Wienerberger, Schlagmann | ≥ 12DF (≥ 373 x 240 x 238) | ≥ 1.2 | 6 | - | 0,43 |

| 8 | - | 0,57 | |||

| 10 | - | 0,71 | |||

| Vertically perforated brick HLz T14-24.06), EN 771-1, Z-17.1-651 e.g. Wienerberger | ≥ 10DF (≥ 308 x 240 x 249) | ≥ 0.7 | 6 | - | 0,17 |

| Vertically perforated brick POROTON T8-306), POROTON T9-306), EN 771-1, T8: Z-17.1-982, T9: Z-17.1-674 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.6 | 6 | - | 0,43 |

| 8 | - | 0,57 | |||

| Vertically perforated brick POROTON S106), EN 771-1, Z-17.1-1017 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | - | 0,43 |

| Vertically perforated brick POROTON S11-306), EN 771-1, Z-17.1-812 Wienerberger, Schlagmann | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.9 | 8 | - | 0,71 |

| Vertically perforated brick ThermoPlan MZ106), EN 771-1, Z-17.1-1015 Mein Ziegelhaus | ≥ 10DF (≥ 248 x 300 x 249) | ≥ 0.75 | 8 | 0,5 | 0,71 |

| Vertically perforated brick ThermoPlan TS2)6), EN 771-1, Z-17.1-993 Mein Ziegelhaus | ≥ 9DF (≥ 373 x 175 x 249) | ≥ 0.9 | 6 | 0,11 | 0,11 |

| 8 | 0,17 | 0,17 | |||

| 10 | 0,21 | 0,21 | |||

| 12 | 0,26 | 0,26 | |||

| 20 | 0,43 | 0,43 | |||

| Vertically perforated brick THERMOPOR TV 9-Plan6), EN 771-1, Z-17.1-1006 Thermopor Ziegel-Kontor Ulm | ≥ 247 x 300 x 249) | ≥ 0.75 | 4 | - | 0,26 |

| 6 | - | 0,43 | |||

| 8 | - | 0,57 | |||

| Hollow calcium silicate block KSL6), EN 771-2, DIN 106-1 e.g. Xella | ≥ 8DF (≥ 248 x 240 x 238) | ≥ 1.4 | 6 | - | 0,34 |

| 8 | - | 0,43 | |||

| 10 | - | 0,57 | |||

| 12 | - | 0,71 | |||

| Hollow concrete block made of lightweight concrete 3K Hbl, EN 771-3, DIN 181516) e.g. Liapor | ≥ 16DF (≥ 498 x 240 x 238) | ≥ 0.7 | 2 | - | 0,14 |

| 4 | - | 0,26 | |||

| 6 | - | 0,43 | |||

| 1) The partial safety factors of the resistances regulated in the approval and a partial safety factor of the effects of γF = 1.4 have been taken into account. For the combination of tensile and transverse loads, please refer to ETAG 020 Appendix C. 2) Maximum long-term temperature. 3) Maximum short-term temperature. 4) For other types of brick, raw densities, minimum compressive strength or temperature ranges, please refer to the approval ETA-11/0309. 5) The brick geometry should be compared with the approval ETA-11/0309. 6) If the drill hole is created through impact or hammer action, the permissible load must be determined by tests on the structure. | |||||