SC 90° countersink DIN 335C

Conical countersink VHM DIN 335 FC

CNTSNK-CONI-90DGR-DIN335C-SC-D12,4MM

Art.-no. 5443100005

EAN 4055375892589

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 6405 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Hard and tough material |

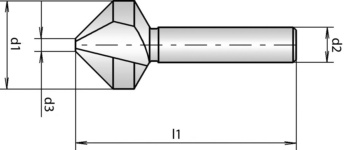

Spot-facer diameter (d1) | 12.4 mm |

Shank diameter (d2) | 8 mm |

Tip diameter (d3) | 2.8 mm |

Length (l1) | 56 mm |

Number of cutting edges (Z) | 3 PCS |

Standards | DIN 335 |

Form | C |

Cutting material | SC |

Countersink angle | 90 Degree |

Surface | Uncoated |

Shank style | Cylindrical |

Suitable for cordless drills (points system) | 1 of 4 points |

Suitable for drill (points system) | 1 of 4 points |

Suitable for upright drilling machine (points system) | 3 of 4 points |

Suitable for milling-drilling centre (points system) | 4 of 4 points |

Service life (points system) | 2 of 4 points |

Countersinking speed (point system) | 2 of 4 points |

Countersinking quality (point system) | 2 of 4 points |

Versatility (points system) | 3 of 4 points |

Countersinking behaviour (point system) | 2 of 4 points |

Tolerance of cutting edge diameter | z9 |

Tolerance of shank diameter | h9 |

Material of sub-group | General structural steels, Non-alloyed tempering steels, Plastics, aramide-fibre reinforced, Alloyed tempering steels, Nitriding steels, Tool steels, High-speed steels, Cast iron, Ductile iron, Malleable cast iron, White cast iron, Stainless steels, austenitic, Stainless steels, sulphurated, Stainless steels, martensitic, Titanium, Titanium alloys, Special alloys, Hardox, Spring steels, Aluminium casting alloys (>10% silicon), Aluminium casting alloys (<10% silicon), Brass, short-chipping, Bronze, short-chipping |

| Cutting values for countersinks, uncoated | ||||||

| For dia. 5.3–14.4 | ||||||

| Material designation | Tensile strength | vc | f | |||

| From | To | Dia. 5.3 | Dia. 6.3/8.3 | Dia. 10.4/12.4/14.4 | ||

| General structural steels | < 500 N/mm² | 55 | 70 | 0,070 | 0,090 | 0,120 |

| 500–850 N/mm² | 55 | 65 | 0,060 | 0,080 | 0,100 | |

| Machining steels | < 850 N/mm² | 55 | 65 | 0,060 | 0,080 | 0,100 |

| 850–1000 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 | |

| Unalloyed heat-treated steels | < 700 N/mm² | 55 | 65 | 0,060 | 0,080 | 0,100 |

| 700–850 N/mm² | 55 | 65 | 0,060 | 0,080 | 0,100 | |

| 850–1000 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 | |

| Alloyed heat-treated steels | 850–1000 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 |

| 1000–1200 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 | |

| Non-alloyed case-hardening steels | < 750 N/mm² | 55 | 65 | 0,060 | 0,080 | 0,100 |

| Alloyed case-hardening steels | < 1000 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 |

| 1000–1200 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 | |

| Nitriding steels | < 1000 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 |

| 1000–1200 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 | |

| Tool steels | < 850 N/mm² | 40 | 55 | 0,040 | 0,060 | 0,080 |

| 850–1100 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 | |

| 1100–1400 N/mm² | 5 | 12 | 0,090 | 0,030 | 0,040 | |

| High-speed steels | 850–1200 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 |

| Hardened steels | 48–55 HRC | 5 | 12 | 0,090 | 0,030 | 0,040 |

| 55–60 HRC | 5 | 12 | 0,090 | 0,030 | 0,040 | |

| Wear-resistant constructional steel | 1350 N/mm² | 5 | 12 | 0,090 | 0,030 | 0,040 |

| 1800 N/mm² | 5 | 12 | 0,090 | 0,030 | 0,040 | |

| Spring steels | < 1200 N/mm² | 13 | 22 | 0,030 | 0,040 | 0,050 |

| Stainless steels, sulphurated | < 700 N/mm² | 10 | 22 | 0,040 | 0,050 | 0,060 |

| Stainless steels, austenitic | < 700 N/mm² | 10 | 22 | 0,040 | 0,050 | 0,060 |

| < 850 N/mm² | 10 | 22 | 0,040 | 0,050 | 0,060 | |

| Stainless steels, martensitic | < 1100 N/mm² | 10 | 22 | 0,040 | 0,050 | 0,060 |

| Special alloys | < 1200 N/mm² | 5 | 12 | 0,090 | 0,030 | 0,040 |

| Cast iron | < 180 HB | 35 | 55 | 0,080 | 0,100 | 0,120 |

| > 180 HB | 20 | 35 | 0,060 | 0,070 | 0,080 | |

| Spheroidal graphite, malleable iron | > 180 HB | 20 | 35 | 0,060 | 0,070 | 0,080 |

| > 260 HB | 20 | 35 | 0,060 | 0,070 | 0,080 | |

| Titanium, titanium alloys | < 850 N/mm² | 10 | 22 | 0,040 | 0,050 | 0,060 |

| Aluminium, aluminium alloys | < 530 N/mm² | 110 | 200 | 0,100 | 0,120 | 0,140 |

| Aluminium, cast aluminium alloys < 10% Si | < 600 N/mm² | 55 | 90 | 0,080 | 0,100 | 0,120 |

| Aluminium, cast aluminium alloys > 10% Si | < 600 N/mm² | 25 | 70 | 0,080 | 0,100 | 0,120 |

| Magnesium, magnesium alloys | < 280 N/mm² | 110 | 200 | 0,100 | 0,120 | 0,140 |

| Copper, low-alloyed | < 350 N/mm² | 55 | 90 | 0,080 | 0,100 | 0,120 |

| Brass, short-chipping | < 600 N/mm² | 110 | 175 | 0,100 | 0,120 | 0,140 |

| Brass, long-chipping | < 600 N/mm² | 70 | 110 | 0,100 | 0,120 | 0,140 |

| Bronze, short-chipping | < 600 N/mm² | 110 | 175 | 0,100 | 0,120 | 0,140 |

| 650–850 N/mm² | 110 | 175 | 0,100 | 0,120 | 0,140 | |

| Bronze, long-chipping | < 850 N/mm² | 70 | 110 | 0,100 | 0,120 | 0,140 |

| 850–1200 N/mm² | 70 | 110 | 0,100 | 0,120 | 0,140 | |

| Graphite | 35 | 55 | 0,080 | 0,100 | 0,120 | |

| Legend | |

| vc = cutting speed [m/min] | |

| f = feed (mm/r) | |

| The suggested cutting values are reference values and must be adapted to the respective conditions. | |

| Cutting values for countersinks, uncoated | ||||||

| For dia. 16.5–31 | ||||||

| Material designation | Tensile strength | vc | f | |||

| From | To | Dia. 16.5/19.5 | Dia. 20.5 | Dia. 25/31 | ||

| General structural steels | < 500 N/mm² | 55 | 70 | 0,140 | 0,160 | 0,200 |

| 500–850 N/mm² | 55 | 65 | 0,120 | 0,140 | 0,180 | |

| Machining steels | < 850 N/mm² | 55 | 65 | 0,120 | 0,140 | 0,180 |

| 850–1000 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 | |

| Unalloyed heat-treated steels | < 700 N/mm² | 55 | 65 | 0,120 | 0,140 | 0,180 |

| 700–850 N/mm² | 55 | 65 | 0,120 | 0,140 | 0,180 | |

| 850–1000 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 | |

| Alloyed heat-treated steels | 850–1000 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 |

| 1000–1200 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 | |

| Non-alloyed case-hardening steels | < 750 N/mm² | 55 | 65 | 0,120 | 0,140 | 0,180 |

| Alloyed case-hardening steels | < 1000 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 |

| 1000–1200 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 | |

| Nitriding steels | < 1000 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 |

| 1000–1200 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 | |

| Tool steels | < 850 N/mm² | 40 | 55 | 0,100 | 0,120 | 0,140 |

| 850–1100 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 | |

| 1100–1400 N/mm² | 5 | 12 | 0,050 | 0,060 | 0,080 | |

| High-speed steels | 850–1200 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 |

| Hardened steels | 48–55 HRC | 5 | 12 | 0,050 | 0,060 | 0,080 |

| 55–60 HRC | 5 | 12 | 0,050 | 0,060 | 0,080 | |

| Wear-resistant constructional steel | 1350 N/mm² | 5 | 12 | 0,050 | 0,060 | 0,080 |

| 1800 N/mm² | 5 | 12 | 0,050 | 0,060 | 0,080 | |

| Spring steels | < 1200 N/mm² | 13 | 22 | 0,090 | 0,080 | 0,100 |

| Stainless steels, sulphurated | < 700 N/mm² | 10 | 22 | 0,070 | 0,080 | 0,090 |

| Stainless steels, austenitic | < 700 N/mm² | 10 | 22 | 0,070 | 0,080 | 0,090 |

| < 850 N/mm² | 10 | 22 | 0,070 | 0,080 | 0,090 | |

| Stainless steels, martensitic | < 1100 N/mm² | 10 | 22 | 0,070 | 0,080 | 0,090 |

| Special alloys | < 1200 N/mm² | 5 | 12 | 0,050 | 0,060 | 0,080 |

| Cast iron | < 180 HB | 35 | 55 | 0,160 | 0,200 | 0,250 |

| > 180 HB | 20 | 35 | 0,120 | 0,160 | 0,200 | |

| Spheroidal graphite, malleable iron | > 180 HB | 20 | 35 | 0,120 | 0,160 | 0,200 |

| > 260 HB | 20 | 35 | 0,120 | 0,160 | 0,200 | |

| Titanium, titanium alloys | < 850 N/mm² | 10 | 22 | 0,070 | 0,080 | 0,090 |

| Aluminium, aluminium alloys | < 530 N/mm² | 110 | 200 | 0,180 | 0,220 | 0,260 |

| Aluminium, cast aluminium alloys < 10% Si | < 600 N/mm² | 55 | 90 | 0,140 | 0,180 | 0,220 |

| Aluminium, cast aluminium alloys > 10% Si | < 600 N/mm² | 25 | 70 | 0,140 | 0,180 | 0,220 |

| Magnesium, magnesium alloys | < 280 N/mm² | 110 | 200 | 0,180 | 0,220 | 0,260 |

| Copper, low-alloyed | < 350 N/mm² | 55 | 90 | 0,140 | 0,180 | 0,220 |

| Brass, short-chipping | < 600 N/mm² | 110 | 175 | 0,180 | 0,200 | 0,240 |

| Brass, long-chipping | < 600 N/mm² | 70 | 110 | 0,180 | 0,200 | 0,240 |

| Bronze, short-chipping | < 600 N/mm² | 110 | 175 | 0,180 | 0,200 | 0,240 |

| 650–850 N/mm² | 110 | 175 | 0,180 | 0,200 | 0,240 | |

| Bronze, long-chipping | < 850 N/mm² | 70 | 110 | 0,180 | 0,200 | 0,240 |

| 850–1200 N/mm² | 70 | 110 | 0,180 | 0,200 | 0,240 | |

| Graphite | 35 | 55 | 0,160 | 0,200 | 0,250 | |