SC Speedcut aluminium end mill, long, optional, triple blade, variable helix DIN 6527L, HA shank

End mill SC Alu DIN6527L Z3-4 3xD72xD HA

ENDMIL-SP-DIN6527L-ALU-SC-HA-D10

Art.-no. 5443300936

EAN 4055375919408

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Particularly suitable for machining aluminium materials (both for cast and wrought alloys). Core increase for greater stability, optimal chip outflow owing to enhanced production grinding procedure for an extremely smooth surface. Maximum cutting volumes and optimal surface quality owing to unique cutter geometry.

Product information

Datasheets(X)

| |

Product code | 7250 |

Material to be processed | Aluminium, Copper, Brass, Plastic |

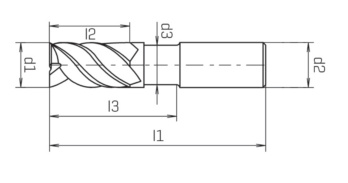

Diameter (d1) | 10 mm |

Shank diameter (d2) | 10 mm |

Clearance diameter (d3) | 9.5 mm |

Standards | DIN 6527 |

Construction length | Long |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | Plain |

Coolant supply | External |

Twist angle | 34-38° |

Length (l1) | 72 mm |

Cutting edge length (l2) | 22 mm |

Clearance length (l3) | 32 mm |

Number of cutting edges (Z) | 3 PCS |

Corner chamfer | 0.15 mm |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Aluminium, Copper, Brass, Plastics |

| Key | ||

| E = emulsion | ae = 0.1xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The cutting speeds listed refer to all tool types according to DIN 6527K or DIN6527L. For XL Series end mills, it is recommended to reduce the cutting speed by 30 %. | ||

| Cutting values for roughing contour | ||||||||

| For dia. 3 to dia. 8 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 500 | 0,035 | 0,041 | 0,048 | 0,055 | 0,070 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 475 | 0,035 | 0,041 | 0,048 | 0,055 | 0,070 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 250 | 0,032 | 0,036 | 0,041 | 0,046 | 0,070 |

| Copper, low-alloy | < 350 N/mm² | E | 135 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 |

| Brass, short-chipping | < 600 N/mm² | E | 250 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 |

| Brass, long-chipping | < 600 N/mm² | E | 175 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 |

| Bronze, short-chipping | < 600 N/mm² | E | 175 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 |

| 650-850 N/mm² | E | 135 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 | |

| Bronze, long-chipping | < 850 N/mm² | E | 135 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 |

| 850-1200 N/mm² | E | 120 | 0,022 | 0,028 | 0,035 | 0,041 | 0,060 | |

| Cutting values for finishing contour | ||||||||

| For dia. 10 - dia. 25 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 10 | Dia. 12 | Dia. 16 | Dia. 20 | Dia. 25 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 580 | 0,096 | 0,108 | 0,132 | 0,168 | 0,204 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 530 | 0,096 | 0,108 | 0,132 | 0,168 | 0,204 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 290 | 0,120 | 0,144 | 0,180 | 0,228 | 0,288 |

| Copper, low-alloy | < 350 N/mm² | E | 160 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 |

| Brass, short-chipping | < 600 N/mm² | E | 290 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 |

| Brass, long-chipping | < 600 N/mm² | E | 205 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 |

| Bronze, short-chipping | < 600 N/mm² | E | 205 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 |

| 650-850 N/mm² | E | 170 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 | |

| Bronze, long-chipping | < 850 N/mm² | E | 170 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 |

| 850-1200 N/mm² | E | 145 | 0,090 | 0,108 | 0,132 | 0,168 | 0,204 | |

| Cutting values for finishing contour | ||||||||

| For dia. 3 to dia. 8 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 3 | Dia. 4 | Dia. 5 | Dia. 6 | Dia. 8 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 580 | 0,053 | 0,057 | 0,061 | 0,066 | 0,084 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 530 | 0,053 | 0,057 | 0,061 | 0,066 | 0,084 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 290 | 0,048 | 0,050 | 0,052 | 0,055 | 0,084 |

| Copper, low-alloy | < 350 N/mm² | E | 160 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 |

| Brass, short-chipping | < 600 N/mm² | E | 290 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 |

| Brass, long-chipping | < 600 N/mm² | E | 205 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 |

| Bronze, short-chipping | < 600 N/mm² | E | 205 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 |

| 650-850 N/mm² | E | 170 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 | |

| Bronze, long-chipping | < 850 N/mm² | E | 170 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 |

| 850-1200 N/mm² | E | 145 | 0,033 | 0,038 | 0,043 | 0,049 | 0,072 | |

| Key | ||

| E = emulsion | ae = 0.5xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The cutting speeds listed refer to all tool types according to DIN 6527K or DIN6527L. For XL Series end mills, it is recommended to reduce the cutting speed by 30 %. | ||

| Cutting values for roughing contour | ||||||||

| For dia. 10 - dia. 25 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 10 | Dia. 12 | Dia. 16 | Dia. 20 | Dia. 25 | ||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 500 | 0,080 | 0,090 | 0,110 | 0,140 | 0,170 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 475 | 0,080 | 0,090 | 0,110 | 0,140 | 0,170 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 250 | 0,100 | 0,120 | 0,150 | 0,190 | 0,240 |

| Copper, low-alloy | < 350 N/mm² | E | 135 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 |

| Brass, short-chipping | < 600 N/mm² | E | 250 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 |

| Brass, long-chipping | < 600 N/mm² | E | 175 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 |

| Bronze, short-chipping | < 600 N/mm² | E | 175 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 |

| 650-850 N/mm² | E | 135 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 | |

| Bronze, long-chipping | < 850 N/mm² | E | 135 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 |

| 850-1200 N/mm² | E | 120 | 0,075 | 0,090 | 0,110 | 0,140 | 0,170 | |