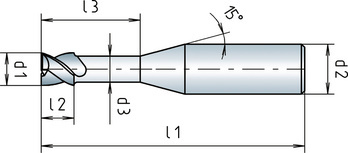

SC mini cutter, twin blade

Mini End mill SC HSC WN Z2 1.5xD/10xD 30° TiAlN HA

CTR-SC-HSC-MINI-WN-S-TN-D0,5MM

Art.-no. 5443301462

EAN 4055375891681

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Recommended for milling materials of medium and high strength and for HSC machining.

Product information

Datasheets(X)

| |

Product code | 6257 |

Material to be processed | Steel, Stainless steel, Hard and tough material, Aluminium |

Shank style | Cylindrical DIN 6535-HA |

Diameter (d1) | 0.5 mm |

Shank diameter (d2) | 3 mm |

Clearance diameter (d3) | 0.45 mm |

Length (l1) | 50 mm |

Cutting edge length (l2) | 0.7 mm |

Clearance length (l3) | 6 mm |

Standards | CS |

Cutting material | SC |

Surface | TiAlN |

Coolant supply | External |

Twist angle | 30° |

Number of cutting edges (Z) | 2 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Stainless steels < 850 N/mm², Steels > 45 HRC, Aluminium |

| Legend | ||

| E = emulsion | ae = 0.1xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1.5xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for finishing contour | ||||||

| For dia. 0.4-3 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 0.4-1 | Dia. 1-1.9 | Dia. 2-3 | ||||

| Carbon steels | 850-1000 N/mm² | E | 140 | 0,002 | 0,005 | 0,009 |

| Unalloyed heat-treated steels | 850-1000 N/mm² | E | 140 | 0,002 | 0,005 | 0,009 |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 120 | 0,002 | 0,005 | 0,009 |

| 1000-1200 N/mm² | E | 95 | 0,002 | 0,004 | 0,008 | |

| Alloyed case-hardening steels | 1000-1200 N/mm² | E | 95 | 0,002 | 0,004 | 0,008 |

| Nitriding steels | 1000-1200 N/mm² | E | 95 | 0,002 | 0,004 | 0,008 |

| Tool steels | 850-1100 N/mm² | E | 95 | 0,002 | 0,004 | 0,008 |

| 1100-1400 N/mm² | E | 85 | 0,002 | 0,004 | 0,008 | |

| High-speed steels | 850-1200 N/mm² | E | 80 | 0,002 | 0,004 | 0,008 |

| Hardened steels | 48-55 HRC | - | 65 | 0,002 | 0,004 | 0,008 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 50 | 0,002 | 0,003 | 0,006 |

| 1800 N/mm² | E | 50 | 0,002 | 0,003 | 0,006 | |

| Spring steels | < 1200 N/mm² | E | 85 | 0,002 | 0,004 | 0,008 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 110 | 0,002 | 0,005 | 0,009 |

| Stainless steels, austenitic | < 700 N/mm² | E | 110 | 0,002 | 0,005 | 0,009 |

| < 850 N/mm² | E | 90 | 0,002 | 0,004 | 0,008 | |

| Aluminium, aluminium alloys | < 530 N/mm² | E | 800 | 0,002 | 0,005 | 0,010 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 600 | 0,002 | 0,005 | 0,010 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 400 | 0,002 | 0,005 | 0,010 |

| Legend | ||

| E = emulsion | ae = 0.5xd1 | |

| vc = cutting speed [m/min] | ||

| fz = feed per tooth [mm/t] | ap = 1xd1 | |

| ae = cutting thickness (radial) | ||

| ap = cutting thickness (axial) | ||

| The suggested cutting values are reference values and must be adapted to the respective conditions. | ||

| Cutting values for roughing contour | ||||||

| For dia. 0.4-3 | ||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||

| Dia. 0.4-1 | Dia. 1-1.9 | Dia. 2-3 | ||||

| Carbon steels | 850-1000 N/mm² | E | 100 | 0,001 | 0,003 | 0,005 |

| Unalloyed heat-treated steels | 850-1000 N/mm² | E | 100 | 0,001 | 0,003 | 0,005 |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 85 | 0,001 | 0,003 | 0,005 |

| 1000-1200 N/mm² | E | 70 | 0,001 | 0,002 | 0,004 | |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 85 | 0,001 | 0,003 | 0,005 |

| 1000-1200 N/mm² | E | 70 | 0,001 | 0,002 | 0,004 | |

| Nitriding steels | < 1000 N/mm² | E | 85 | 0,001 | 0,003 | 0,005 |

| 1000-1200 N/mm² | E | 70 | 0,001 | 0,002 | 0,004 | |

| Tool steels | 850-1100 N/mm² | E | 70 | 0,001 | 0,002 | 0,004 |

| 1100-1400 N/mm² | E | 60 | 0,001 | 0,002 | 0,004 | |

| High-speed steels | 850-1200 N/mm² | E | 60 | 0,001 | 0,002 | 0,004 |

| Wear-resistant constructional steel | 1350 N/mm² | E | 50 | 0,001 | 0,003 | 0,006 |

| 1800 N/mm² | E | 45 | 0,001 | 0,003 | 0,006 | |

| Spring steels | < 1200 N/mm² | E | 70 | 0,001 | 0,002 | 0,004 |

| Stainless steels, sulphurated | < 700 N/mm² | E | 90 | 0,001 | 0,003 | 0,006 |

| Stainless steels, austenitic | < 700 N/mm² | E | 85 | 0,001 | 0,003 | 0,006 |

| < 850 N/mm² | E | 85 | 0,001 | 0,002 | 0,004 | |

| Special alloys | < 1200 N/mm² | E | 45 | 0,001 | 0,003 | 0,006 |

| Aluminium, aluminium alloys | < 530 N/mm² | E | 350 | 0,002 | 0,004 | 0,007 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 300 | 0,002 | 0,004 | 0,007 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm131 | E | 220 | 0,002 | 0,004 | 0,007 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 350 | 0,002 | 0,004 | 0,007 |

| Graphite | - | 130 | 0,002 | 0,004 | 0,007 | |