SC twist drill bit DIN 6537K

Twist drill SD DIN6537K type H TiAlN-S UHS

DRL-TWST-DIN6537K-HS-IC-SC-TNS-HA-D4,5MM

Art.-no. 5443002477

EAN 4055375915998

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Specially designed for machining high strength and hardened steels up to 68 HRC. Very high level of stability and low wear due to convex cutting edge geometry. Special geometry for optimum chip breaking, high centring accuracy and low cutting forces.

Product information

Datasheets(X)

| |

Product code | 6857 |

Material to be processed | Cast metal, Hard and tough material |

Standards | DIN 6537 |

Design | Short |

Surface | TiAlN-S |

Max. drilling depth (D) | 3xD |

Cutting material | SC |

Number of guiding chamfers | 2 PCS |

Angle of the tip | 140 Degree |

Number of cutting edges | 2 PCS |

Coolant supply | External |

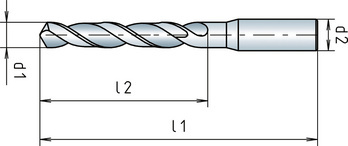

Diameter (d1) | 4.5 mm |

Shank style | Cylindrical DIN 6535-HA |

Length (l1) | 66 mm |

Chip flute length (l2) | 24 mm |

Tolerance of cutting edge diameter | h7 |

Shank diameter (d2) | 6 mm |

Tolerance of shank diameter | h6 |

Material of sub-group | Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Steels > 45 HRC |

| Cutting values for solid carbide high-performance drill Speeddrill, ultra-hard steel, 68 HRC 3xd without internal cooling | |||||

| For dia. 3 to dia. 8.9 | |||||

| Material designation | Tensile strength | Cooling | vc | f | |

| Dia. 3 to dia. 5.9 | Dia. 6 to dia. 8.9 | ||||

| General structural steels | < 500 N/mm² | E | 80 | 0,180 | 0,240 |

| 500-850 N/mm² | E | 70 | 0,180 | 0,240 | |

| Carbon steels | < 850 N/mm² | E | 80 | 0,180 | 0,240 |

| 850-1,000 N/mm² | E | 70 | 0,180 | 0,240 | |

| Unalloyed hardened steels | < 700 N/mm² | E | 65 | 0,150 | 0,210 |

| 700-850 N/mm² | E | 65 | 0,150 | 0,210 | |

| 850-1,000 N/mm² | E | 65 | 0,150 | 0,210 | |

| Alloyed hardened steels | 850-1,000 N/mm² | E | 65 | 0,150 | 0,210 |

| 1,000-1,200 N/mm² | E | 50 | 0,150 | 0,210 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 75 | 0,180 | 0,240 |

| Alloyed case-hardening steels | < 1,000 N/mm² | E | 70 | 0,180 | 0,240 |

| 1,000-1,200 N/mm² | E | 65 | 0,160 | 0,220 | |

| Nitriding steels | < 1,000 N/mm² | 65 | 0,150 | 0,210 | |

| 1,000-1,200 N/mm² | E | 65 | 0,150 | 0,210 | |

| Tool steels | < 850 N/mm² | E | 50 | 0,150 | 0,210 |

| 850-1,100 N/mm² | E | 50 | 0,150 | 0,210 | |

| Hardened steels | 40-48 HRC | E | 28 | 0,080 | 0,090 |

| 48-55 HRC | E | 20 | 0,080 | 0,090 | |

| 55-60 HRC | E | 16 | 0,080 | 0,090 | |

| 60-68 HRC | E | 10 | 0,080 | 0,090 | |

| Spring steels | < 1,200 N/mm² | E | 40 | 0,150 | 0,210 |

| Cast iron | < 180 HB | T/E | 75 | 0,230 | 0,340 |

| > 180 HB | T/E | 70 | 0,230 | 0,340 | |

| Spheroidal graphite, malleable iron | > 180 HB | E | 75 | 0,200 | 0,250 |

| > 260 HB | E | 70 | 0,200 | 0,250 | |

| Key |

| T = dry |

| E = emulsion |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for solid carbide high-performance drill Speeddrill, ultra-hard steel, 68 HRC 3xd without internal cooling | |||||

| For dia. 9 to dia. 16 | |||||

| Material designation | Tensile strength | Cooling | vc | f | |

| Dia. 9 to dia. 11.9 | Dia. 12 to dia. 16 | ||||

| General structural steels | < 500 N/mm² | E | 80 | 0,300 | 0,350 |

| 500-850 N/mm² | E | 70 | 0,300 | 0,350 | |

| Carbon steels | < 850 N/mm² | E | 80 | 0,300 | 0,350 |

| 850-1,000 N/mm² | E | 70 | 0,300 | 0,350 | |

| Unalloyed hardened steels | < 700 N/mm² | E | 65 | 0,270 | 0,320 |

| 700-850 N/mm² | E | 65 | 0,270 | 0,320 | |

| 850-1,000 N/mm² | E | 65 | 0,270 | 0,320 | |

| Alloyed hardened steels | 850-1,000 N/mm² | E | 65 | 0,270 | 0,320 |

| 1,000-1,200 N/mm² | E | 50 | 0,270 | 0,320 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 75 | 0,300 | 0,350 |

| Alloyed case-hardening steels | < 1,000 N/mm² | E | 70 | 0,300 | 0,350 |

| 1,000-1,200 N/mm² | E | 65 | 0,280 | 0,340 | |

| Nitriding steels | < 1,000 N/mm² | 65 | 0,270 | 0,320 | |

| 1,000-1,200 N/mm² | E | 65 | 0,270 | 0,320 | |

| Tool steels | < 850 N/mm² | E | 50 | 0,270 | 0,320 |

| 850-1,100 N/mm² | E | 50 | 0,270 | 0,320 | |

| Hardened steels | 40-48 HRC | E | 28 | 0,110 | 0,130 |

| 48-55 HRC | E | 20 | 0,110 | 0,130 | |

| 55-60 HRC | E | 16 | 0,110 | 0,130 | |

| 60-68 HRC | E | 10 | 0,110 | 0,130 | |

| Spring steels | < 1,200 N/mm² | E | 40 | 0,270 | 0,320 |

| Cast iron | < 180 HB | T/E | 75 | 0,430 | 0,520 |

| > 180 HB | T/E | 70 | 0,430 | 0,520 | |

| Spheroidal graphite, malleable iron | > 180 HB | E | 75 | 0,350 | 0,400 |

| > 260 HB | E | 70 | 0,350 | 0,400 | |