STC end mill Speedtwister-Inox, extra long XL, five cutting edges, uneven angle of twist gradient, 5xD

End mill Speedtwister Inox WN 5xD type N

ENDMIL-SHA-STW-WN-XL-STC-IX-UD-HB-D12

Art.-no. 5443310604

EAN 4062856187195

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 6197 |

Material to be processed | Steel, Stainless steel, Aluminium, Titanium |

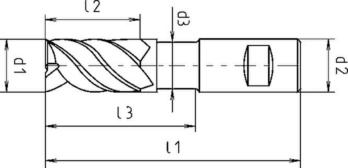

Diameter (d1) | 12 mm |

Shank diameter (d2) | 12 mm |

Standards | CS |

Construction length | Extra long |

Shank style | Cylindrical DIN 6535-HB |

Cutting material | SC |

Surface | ULTRADUR |

Coolant supply | External |

Twist angle | 45° Vario |

Length (l1) | 115 mm |

Cutting edge length (l2) | 62 mm |

Number of cutting edges (Z) | 5 PCS |

Corner chamfer | 0.05 mm |

Tolerance of cutting edge diameter | f8 |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Aluminium |

| Key |

| L = air |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae(radial cutting thickness) = 0.03xd1-0.14xd1 |

| ap (axial cutting thickness) = 5xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. Choosing the right mount is a critical factor in trochoidal machining. The best results were achieved with an IC Weldon tool holder (balancing quality G2.5/18,000 rpm). |

| Cutting values for static contour | ||||||||||

| For dia. 6-10 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 6 | Dia. 8 | Dia. 10 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | |||

| Steels | ||||||||||

| General structural steels | < 500 N/mm² | L + E | 231 | 504 | 0,050 | 0,101 | 0,063 | 0,126 | 0,083 | 0,165 |

| 500-850 N/mm² | L + E | 187 | 408 | 0,045 | 0,090 | 0,063 | 0,126 | 0,076 | 0,151 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 408 | 0,045 | 0,090 | 0,063 | 0,126 | 0,076 | 0,151 |

| 850-1000 N/mm² | L + E | 176 | 384 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 181 | 396 | 0,050 | 0,101 | 0,063 | 0,126 | 0,083 | 0,165 |

| 700-850 N/mm² | L + E | 181 | 396 | 0,045 | 0,090 | 0,063 | 0,126 | 0,078 | 0,157 | |

| 850-1000 N/mm² | L + E | 181 | 396 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 384 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 504 | 0,050 | 0,101 | 0,063 | 0,126 | 0,083 | 0,165 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 384 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 384 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,038 | 0,076 | 0,045 | 0,090 | 0,057 | 0,115 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 408 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 |

| 850-1100 N/mm² | L + E | 176 | 384 | 0,032 | 0,064 | 0,045 | 0,090 | 0,063 | 0,126 | |

| High-speed steels | 850-1200 N/mm² | L + E | 104 | 228 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 |

| Spring steels | < 1200 N/mm² | L + E | 104 | 228 | 0,032 | 0,064 | 0,038 | 0,076 | 0,050 | 0,101 |

| High grade steels | ||||||||||

| Stainless steels, sulphurated | < 700 N/mm² | E | 126 | 276 | 0,038 | 0,076 | 0,050 | 0,101 | 0,070 | 0,140 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 264 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 |

| < 850 N/mm² | E | 104 | 228 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 192 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 |

| Special alloys | < 1200 N/mm² | E | 71 | 156 | 0,032 | 0,064 | 0,045 | 0,090 | 0,057 | 0,115 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 144 | 0,038 | 0,076 | 0,050 | 0,101 | 0,063 | 0,126 |

| Cutting values for dynamic contour | ||||||||

| For dia. 12-16 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 12 | Dia. 16 | |||||||

| min. | max. | min. | max. | min. | max. | |||

| Steels | ||||||||

| General structural steels | < 500 N/mm² | L + E | 231 | 525 | 0,101 | 0,209 | 0,120 | 0,249 |

| 500-850 N/mm² | L + E | 187 | 425 | 0,095 | 0,197 | 0,113 | 0,235 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 425 | 0,088 | 0,183 | 0,113 | 0,235 |

| 850-1000 N/mm² | L + E | 176 | 400 | 0,083 | 0,171 | 0,101 | 0,209 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 181 | 412 | 0,101 | 0,209 | 0,120 | 0,249 |

| 700-850 N/mm² | L + E | 181 | 412 | 0,095 | 0,197 | 0,113 | 0,235 | |

| 850-1000 N/mm² | L + E | 181 | 412 | 0,083 | 0,171 | 0,101 | 0,209 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 400 | 0,076 | 0,157 | 0,101 | 0,209 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,070 | 0,145 | 0,076 | 0,157 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 525 | 0,101 | 0,209 | 0,120 | 0,248 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 400 | 0,083 | 0,171 | 0,101 | 0,209 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,076 | 0,157 | 0,088 | 0,183 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 400 | 0,083 | 0,171 | 0,101 | 0,209 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,063 | 0,131 | 0,076 | 0,157 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 425 | 0,083 | 0,171 | 0,101 | 0,209 |

| 850-1100 N/mm² | L + E | 176 | 400 | 0,076 | 0,157 | 0,088 | 0,183 | |

| High-speed steels | 850-1200 N/mm² | L + E | 104 | 237 | 0,076 | 0,157 | 0,088 | 0,183 |

| Spring steels | < 1200 N/mm² | L + E | 104 | 237 | 0,057 | 0,119 | 0,063 | 0,131 |

| High grade steels | ||||||||

| Stainless steels, sulphurated | < 700 N/mm² | E | 126 | 287 | 0,083 | 0,171 | 0,101 | 0,209 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 275 | 0,076 | 0,157 | 0,088 | 0,183 |

| < 850 N/mm² | E | 104 | 237 | 0,076 | 0,157 | 0,088 | 0,183 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 200 | 0,078 | 0,162 | 0,088 | 0,183 |

| Special alloys | < 1200 N/mm² | E | 71 | 162 | 0,063 | 0,131 | 0,083 | 0,171 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 150 | 0,076 | 0,157 | 0,088 | 0,183 |

| Cutting values for dynamic contour | ||||||||||

| For dia. 6-10 | ||||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||||

| Dia. 6 | Dia. 8 | Dia. 10 | ||||||||

| min. | max. | min. | max. | min. | max. | min. | max. | |||

| Steels | ||||||||||

| General structural steels | < 500 N/mm² | L + E | 231 | 525 | 0,050 | 0,104 | 0,063 | 0,131 | 0,083 | 0,171 |

| 500-850 N/mm² | L + E | 187 | 425 | 0,045 | 0,093 | 0,063 | 0,131 | 0,076 | 0,157 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 425 | 0,045 | 0,093 | 0,063 | 0,131 | 0,076 | 0,157 |

| 850-1000 N/mm² | L + E | 176 | 400 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 181 | 412 | 0,050 | 0,104 | 0,063 | 0,131 | 0,083 | 0,171 |

| 700-850 N/mm² | L + E | 181 | 412 | 0,045 | 0,093 | 0,063 | 0,131 | 0,078 | 0,162 | |

| 850-1000 N/mm² | L + E | 181 | 412 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 400 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 525 | 0,050 | 0,104 | 0,063 | 0,131 | 0,083 | 0,171 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 400 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 400 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 |

| 1000-1200 N/mm² | L + E | 154 | 350 | 0,038 | 0,078 | 0,045 | 0,093 | 0,057 | 0,119 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 425 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 |

| 850-1100 N/mm² | L + E | 176 | 400 | 0,032 | 0,067 | 0,045 | 0,093 | 0,063 | 0,131 | |

| High-speed steels | 850-1200 N/mm² | L + E | 104 | 237 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 |

| Spring steels | < 1200 N/mm² | L + E | 104 | 237 | 0,032 | 0,067 | 0,038 | 0,078 | 0,050 | 0,104 |

| High grade steels | ||||||||||

| Stainless steels, sulphurated | < 700 N/mm² | E | 126 | 287 | 0,038 | 0,078 | 0,050 | 0,104 | 0,070 | 0,145 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 275 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 |

| < 850 N/mm² | E | 104 | 237 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 200 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 |

| Special alloys | < 1200 N/mm² | E | 71 | 162 | 0,032 | 0,067 | 0,045 | 0,093 | 0,057 | 0,119 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 150 | 0,038 | 0,078 | 0,050 | 0,104 | 0,063 | 0,131 |

| Key |

| L = air |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae(radial cutting thickness) = 0.03xd1-0.14xd1 |

| ap (axial cutting thickness) = 5xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. Choosing the right mount is a critical factor in trochoidal machining. The best results were achieved with an IC Weldon tool holder (balancing quality G2.5/18,000 rpm). |

| Cutting values for static contour | ||||||||

| For dia. 12-16 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 12 | Dia. 16 | |||||||

| min. | max. | min. | max. | min. | max. | |||

| Steels | ||||||||

| General structural steels | < 500 N/mm² | L + E | 231 | 504 | 0,101 | 0,202 | 0,120 | 0,241 |

| 500-850 N/mm² | L + E | 187 | 408 | 0,095 | 0,190 | 0,113 | 0,227 | |

| Carbon steels | < 850 N/mm² | L + E | 187 | 408 | 0,088 | 0,176 | 0,113 | 0,227 |

| 850-1000 N/mm² | L + E | 176 | 384 | 0,083 | 0,165 | 0,101 | 0,202 | |

| Unalloyed heat-treated steels | < 700 N/mm² | L + E | 181 | 396 | 0,101 | 0,202 | 0,120 | 0,241 |

| 700-850 N/mm² | L + E | 181 | 396 | 0,095 | 0,190 | 0,113 | 0,227 | |

| 850-1000 N/mm² | L + E | 181 | 396 | 0,083 | 0,165 | 0,101 | 0,202 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | L + E | 176 | 384 | 0,076 | 0,151 | 0,101 | 0,202 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,070 | 0,140 | 0,076 | 0,151 | |

| Unalloyed case-hardening steels | < 750 N/mm² | L + E | 231 | 504 | 0,101 | 0,202 | 0,120 | 0,239 |

| Alloyed case-hardening steels | < 1000 N/mm² | L + E | 176 | 384 | 0,083 | 0,165 | 0,101 | 0,202 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,076 | 0,151 | 0,088 | 0,176 | |

| Nitriding steels | < 1000 N/mm² | L + E | 176 | 384 | 0,083 | 0,165 | 0,101 | 0,202 |

| 1000-1200 N/mm² | L + E | 154 | 336 | 0,063 | 0,126 | 0,076 | 0,151 | |

| Tool steels | < 850 N/mm² | L + E | 187 | 408 | 0,083 | 0,165 | 0,101 | 0,202 |

| 850-1100 N/mm² | L + E | 176 | 384 | 0,076 | 0,151 | 0,088 | 0,176 | |

| High-speed steels | 850-1200 N/mm² | L + E | 104 | 228 | 0,076 | 0,151 | 0,088 | 0,176 |

| Spring steels | < 1200 N/mm² | L + E | 104 | 228 | 0,057 | 0,115 | 0,063 | 0,126 |

| High grade steels | ||||||||

| Stainless steels, sulphurated | < 700 N/mm² | E | 126 | 276 | 0,083 | 0,165 | 0,101 | 0,202 |

| Stainless steels, austenitic | < 700 N/mm² | E | 121 | 264 | 0,076 | 0,151 | 0,088 | 0,176 |

| < 850 N/mm² | E | 104 | 228 | 0,076 | 0,151 | 0,088 | 0,176 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 88 | 192 | 0,078 | 0,157 | 0,088 | 0,176 |

| Special alloys | < 1200 N/mm² | E | 71 | 156 | 0,063 | 0,126 | 0,083 | 0,165 |

| Titanium, titanium alloys | < 850 N/mm² | E | 66 | 144 | 0,076 | 0,151 | 0,088 | 0,176 |