Solid carbide single-tooth cutter, plastic, right-hand cutting with left twist

Single-tooth cutter SC HSC WN RL typeW HA plastics

CTR-SNGLTO-WN-PVC-SC-W-D12,0MM

Art.-no. 5443301641

EAN 4055375891391

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Right-hand cutting with left-hand spiral. Suitable for machining all plastics, fibreglass-reinforced polyester and graphite.

Product information

Datasheets(X)

| |

Product code | 6215 |

Material to be processed | Aluminium, Plastic |

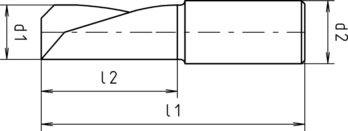

Diameter (d1) | 12 mm |

Shank diameter (d2) | 12 mm |

Standards | CS |

Shank style | Cylindrical DIN 6535-HA |

Cutting material | SC |

Surface | Plain |

Coolant supply | External |

Twist angle | 30° |

Length (l1) | 73 mm |

Cutting edge length (l2) | 30 mm |

Number of cutting edges (Z) | 1 PCS |

Tolerance of cutting edge diameter | h10 |

Tolerance of shank diameter | h6 |

Material of sub-group | Aluminium, Plastics |

| Cutting values for finishing contour | ||||||||

| For dia. 2-12 | ||||||||

| Material designation | Tensile strength | Cooling | vc | fz | ||||

| Dia. 2-3.9 | Dia. 4-5.9 | Dia. 6-7.9 | Dia. 8-9.9 | Dia. 10-12 | ||||

| Cast metals | ||||||||

| Graphite | - | 90 | 0,012 | 0,020 | 0,027 | 0,054 | 0,072 | |

| Non-ferrous metals | ||||||||

| Aluminium, aluminium alloys | < 530 N/mm² | E | 400 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 |

| Aluminium, cast aluminium alloys < 10 % Si | < 600 N/mm² | E | 300 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 |

| Aluminium, cast aluminium alloys > 10 % Si | < 600 N/mm² | E | 250 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 |

| Magnesium, magnesium alloys | < 280 N/mm² | E | 400 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 |

| Plastics | ||||||||

| Plastics, thermoplastic | - | 150 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 | |

| Plastics, duroplastic | - | 80 | 0,012 | 0,024 | 0,031 | 0,047 | 0,063 | |

| Legend |

| E = emulsion |

| vc = cutting speed [m/min] |

| fz = feed per tooth [mm/t] |

| ae (radial cutting thickness) = 0.1xd1 |

| ap (axial cutting thickness) = 1.5xd1 |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |