Solid carbide twist drill bit, internal cooling For universal applications and considerable drilling depths up to 12xd

Twist drill bit SD WN-XL 12xD type N IC TiAlN-S Uni

DRL-TWST-WN12XD-UV-IC-SC-TNS-HB-D7,0MM

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 6757 |

Material to be processed | Steel, Cast metal, Stainless steel, Titanium, Copper, Brass, Aluminium |

Standards | CS |

Design | Extra long |

Surface | TiAlN-S |

Max. drilling depth (D) | 12xD |

Cutting material | SC |

Number of guiding chamfers | 4 PCS |

Angle of the tip | 135 Degree |

Number of cutting edges | 2 PCS |

Coolant supply | Internal |

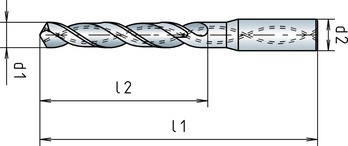

Diameter (d1) | 7.0 mm |

Shank style | Cylindrical DIN 6535-HB |

Length (l1) | 146 mm |

Chip flute length (l2) | 108 mm |

Tolerance of cutting edge diameter | h7 |

Shank diameter (d2) | 8 mm |

Tolerance of shank diameter | h6 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Malleable cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Titanium, Titanium alloys, Copper, Brass, Aluminium |

| Cutting values for solid carbide high-performance drill Speeddrill, 12xd1 with internal cooling | |||||

| For dia. 3 to dia. 8.9 | |||||

| Material designation | Tensile strength | Cooling | vc | f | |

| Dia. 3 to dia. 5.9 | Dia. 6 to dia. 8.9 | ||||

| General structural steels | < 500 N/mm² | E | 105 | 0,160 | 0,220 |

| 500-850 N/mm² | E | 90 | 0,160 | 0,220 | |

| Carbon steels | < 850 N/mm² | E | 105 | 0,160 | 0,220 |

| 850-1000 N/mm² | E | 90 | 0,160 | 0,220 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 85 | 0,150 | 0,210 |

| 700-850 N/mm² | E | 85 | 0,150 | 0,210 | |

| 850-1000 N/mm² | E | 85 | 0,080 | 0,120 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 85 | 0,080 | 0,120 |

| 1000-1200 N/mm² | E | 80 | 0,080 | 0,120 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 90 | 0,160 | 0,220 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 85 | 0,160 | 0,220 |

| 1000-1200 N/mm² | E | 80 | 0,150 | 0,210 | |

| Nitriding steels | < 1000 N/mm² | E | 85 | 0,080 | 0,120 |

| 1000-1200 N/mm² | E | 80 | 0,080 | 0,120 | |

| Tool steels | < 850 N/mm² | E | 75 | 0,080 | 0,120 |

| 850-1100 N/mm² | E | 65 | 0,080 | 0,120 | |

| Stainless steels, sulphurated | < 700 N/mm² | E | 75 | 0,080 | 0,120 |

| Stainless steels, austenitic | < 700 N/mm² | E | 65 | 0,080 | 0,120 |

| < 850 N/mm² | E | 65 | 0,080 | 0,120 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 60 | 0,080 | 0,120 |

| Cast iron | < 180 HB | E | 110 | 0,200 | 0,250 |

| > 180 HB | E | 105 | 0,200 | 0,250 | |

| Nodular graphite, malleable iron | > 180 HB | E | 105 | 0,130 | 0,180 |

| > 260 HB | E | 105 | 0,130 | 0,180 | |

| Titanium, titanium alloys | < 850 N/mm² | D/E | 40 | 0,040 | 0,080 |

| Legend |

| D = pneumatic |

| E = emulsion |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values for solid carbide high-performance drill Speeddrill, 12xd1 with internal cooling | |||||

| For dia. 9 to dia. 16 | |||||

| Material designation | Tensile strength | Cooling | vc | f | |

| Dia. 9 to dia. 11.9 | Dia. 12 to dia. 16 | ||||

| General structural steels | < 500 N/mm² | E | 105 | 0,280 | 0,340 |

| 500-850 N/mm² | E | 90 | 0,280 | 0,340 | |

| Carbon steels | < 850 N/mm² | E | 105 | 0,280 | 0,340 |

| 850-1000 N/mm² | E | 90 | 0,280 | 0,340 | |

| Unalloyed heat-treated steels | < 700 N/mm² | E | 85 | 0,270 | 0,320 |

| 700-850 N/mm² | E | 85 | 0,270 | 0,320 | |

| 850-1000 N/mm² | E | 85 | 0,150 | 0,200 | |

| Alloyed heat-treated steels | 850-1000 N/mm² | E | 85 | 0,150 | 0,200 |

| 1000-1200 N/mm² | E | 80 | 0,150 | 0,200 | |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 90 | 0,280 | 0,340 |

| Alloyed case-hardening steels | < 1000 N/mm² | E | 85 | 0,280 | 0,340 |

| 1000-1200 N/mm² | E | 80 | 0,270 | 0,320 | |

| Nitriding steels | < 1000 N/mm² | E | 85 | 0,150 | 0,200 |

| 1000-1200 N/mm² | E | 80 | 0,150 | 0,200 | |

| Tool steels | < 850 N/mm² | E | 75 | 0,150 | 0,200 |

| 850-1100 N/mm² | E | 65 | 0,150 | 0,200 | |

| Stainless steels, sulphurated | < 700 N/mm² | E | 75 | 0,150 | 0,200 |

| Stainless steels, austenitic | < 700 N/mm² | E | 65 | 0,150 | 0,200 |

| < 850 N/mm² | E | 65 | 0,150 | 0,200 | |

| Stainless steels, martensitic | < 1100 N/mm² | E | 60 | 0,150 | 0,200 |

| Cast iron | < 180 HB | E | 110 | 0,350 | 0,400 |

| > 180 HB | E | 105 | 0,350 | 0,400 | |

| Nodular graphite, malleable iron | > 180 HB | E | 105 | 0,230 | 0,300 |

| > 260 HB | E | 105 | 0,230 | 0,300 | |

| Titanium, titanium alloys | < 850 N/mm² | D/E | 40 | 0,120 | 0,160 |