Speeddrill+ Universal solid carbide twist drill bit DIN 6537K, short 3xD, 2 drill heels

Twist drill bit SD+ DIN6537 3xD type N ALTINDUR pl

DRL-SDPLUS-3XD-UV-SC-HB-D10,0MM

Art.-no. 5443932286

EAN 4065746518871

Register now and access more than 125,000 products

Datasheets(X)

| |

Product code | 6728 |

Material to be processed | Steel, Cast metal, Stainless steel, Copper, Brass, Aluminium |

Standards | DIN 6537 |

Design | Short |

Surface | ALTINDUR |

Max. drilling depth (D) | 3xD |

Cutting material | SC |

Number of guiding chamfers | 2 PCS |

Angle of the tip | 140 Degree |

Number of cutting edges | 2 PCS |

Coolant supply | No |

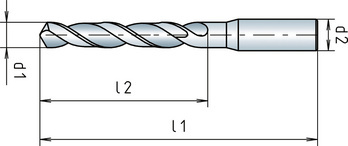

Diameter (d1) | 10.0 mm |

Shank style | Cylindrical DIN 6535-HB |

Length (l1) | 89 mm |

Chip flute length (l2) | 47 mm |

Tolerance of cutting edge diameter | h7 |

Shank diameter (d2) | 10 mm |

Tolerance of shank diameter | h5 |

Material of sub-group | General structural steels, Non-alloyed tempering steels < 1000 N/mm², Alloyed tempering steels < 1000 N/mm², Nitriding steels < 1300 N/mm², Grey cast iron, Stainless steels < 850 N/mm², Stainless steels > 850 N/mm², Copper, Brass, Aluminium |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values and must be adapted to the respective conditions. |

| Cutting values | |||||||

| For dia. 1 to dia. 4.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 1 to dia. 1.9 | Dia. 2 to dia. 2.9 | Dia. 3 to dia. 3.9 | Dia. 4 to dia. 4.9 | ||||

| Steels | |||||||

| General structural steels | < 500 N/mm² | E | 98 | 0,032 | 0,064 | 0,094 | 0,136 |

| General structural steels | 500-850 N/mm² | E | 92 | 0,032 | 0,064 | 0,094 | 0,136 |

| Carbon steels | < 850 N/mm² | E | 98 | 0,032 | 0,064 | 0,094 | 0,136 |

| Unalloyed quenched and tempered steels | < 800 N/mm² | E | 69 | 0,032 | 0,064 | 0,094 | 0,136 |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | E | 81 | 0,032 | 0,064 | 0,094 | 0,136 |

| Alloyed quenched and tempered steels | 1,000-1,200 N/mm² | E | 63 | 0,032 | 0,064 | 0,094 | 0,136 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 96 | 0,032 | 0,064 | 0,094 | 0,136 |

| Alloyed case-hardening steels | 800-1,200 N/mm² | E | 87 | 0,032 | 0,064 | 0,094 | 0,136 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 81 | 0,032 | 0,064 | 0,094 | 0,136 |

| Unalloyed tool steels | < 850 N/mm² | E | 69 | 0,032 | 0,064 | 0,094 | 0,136 |

| Tool steels for cold applications | < 850 N/mm² | E | 69 | 0,032 | 0,064 | 0,094 | 0,136 |

| Tool steels for cold applications | 850-1,100 N/mm² | E | 56 | 0,022 | 0,036 | 0,052 | 0,074 |

| Tool steels for hot applications | 1,100-1,400 N/mm² | E | 35 | 0,022 | 0,026 | 0,052 | 0,068 |

| Spring steels | 800-1,200 N/mm² | E | 58 | 0,026 | 0,034 | 0,052 | 0,074 |

| Stainless steels | |||||||

| Stainless steels | < 850 N/mm² | E | 48 | 0,022 | 0,026 | 0,052 | 0,068 |

| Stainless steels | > 850 N/mm² | E | 42 | 0,022 | 0,026 | 0,052 | 0,068 |

| Cast metals | |||||||

| Grey cast iron | < 180 HB | E | 92 | 0,048 | 0,090 | 0,132 | 0,210 |

| Spheroidal graphite iron | < 180 HB | E | 86 | 0,026 | 0,052 | 0,078 | 0,126 |

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 189 | 0,051 | 0,093 | 0,126 | 0,176 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Short-chipping bronze | < 600 N/mm² | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Short-chipping brass | < 600 N/mm² | E | 189 | 0,051 | 0,093 | 0,126 | 0,176 |

| Long-chipping brass | < 600 N/mm² | E | 189 | 0,051 | 0,093 | 0,126 | 0,176 |

| Long-chipping bronze | < 850 N/mm² | E | 151 | 0,051 | 0,093 | 0,126 | 0,176 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 340 | 0,085 | 0,168 | 0,210 | 0,235 |

| Aluminium alloys | < 400 N/mm² | E | 377 | 0,085 | 0,168 | 0,210 | 0,235 |

| Cutting values | ||||||

| For dia. 17 to dia. 20 | ||||||

| Material designation | Tensile strength | Cooling | vc | f | ||

| Dia. 17 to dia. 17.9 | Dia. 18 to dia. 18.9 | Dia. 19 to dia. 20 | ||||

| Steels | ||||||

| General structural steels | < 500 N/mm² | E | 98 | 0,360 | 0,370 | 0,380 |

| General structural steels | 500-850 N/mm² | E | 92 | 0,360 | 0,370 | 0,380 |

| Carbon steels | < 850 N/mm² | E | 98 | 0,360 | 0,370 | 0,380 |

| Unalloyed quenched and tempered steels | < 800 N/mm² | E | 69 | 0,360 | 0,370 | 0,380 |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | E | 81 | 0,360 | 0,370 | 0,380 |

| Alloyed quenched and tempered steels | 1,000-1,200 N/mm² | E | 63 | 0,360 | 0,370 | 0,380 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 96 | 0,360 | 0,370 | 0,380 |

| Alloyed case-hardening steels | 800-1,200 N/mm² | E | 87 | 0,360 | 0,370 | 0,380 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 81 | 0,360 | 0,370 | 0,380 |

| Unalloyed tool steels | < 850 N/mm² | E | 69 | 0,360 | 0,370 | 0,380 |

| Tool steels for cold applications | < 850 N/mm² | E | 69 | 0,360 | 0,370 | 0,380 |

| Tool steels for cold applications | 850-1,100 N/mm² | E | 56 | 0,274 | 0,284 | 0,294 |

| Tool steels for hot applications | 1,100-1,400 N/mm² | E | 35 | 0,230 | 0,240 | 0,250 |

| Spring steels | 800-1,200 N/mm² | E | 58 | 0,250 | 0,260 | 0,270 |

| Stainless steels | ||||||

| Stainless steels | < 850 N/mm² | E | 48 | 0,262 | 0,274 | 0,286 |

| Stainless steels | > 850 N/mm² | E | 42 | 0,262 | 0,274 | 0,286 |

| Cast metals | ||||||

| Grey cast iron | < 180 HB | E | 92 | 0,438 | 0,448 | 0,458 |

| Spheroidal graphite iron | < 180 HB | E | 86 | 0,370 | 0,370 | 0,374 |

| Non-ferrous metals | ||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 151 | 0,446 | 0,456 | 0,466 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 189 | 0,446 | 0,456 | 0,466 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 151 | 0,446 | 0,456 | 0,466 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 151 | 0,446 | 0,456 | 0,466 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 151 | 0,446 | 0,456 | 0,466 |

| Short-chipping bronze | < 600 N/mm² | E | 151 | 0,446 | 0,456 | 0,466 |

| Short-chipping brass | < 600 N/mm² | E | 189 | 0,446 | 0,456 | 0,466 |

| Long-chipping brass | < 600 N/mm² | E | 189 | 0,446 | 0,456 | 0,466 |

| Long-chipping bronze | < 850 N/mm² | E | 151 | 0,446 | 0,456 | 0,466 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 340 | 0,565 | 0,574 | 0,584 |

| Aluminium alloys | < 400 N/mm² | E | 377 | 0,565 | 0,574 | 0,584 |

| Cutting values | |||||||

| For dia. 13 to dia. 16.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 13 to dia. 13.9 | Dia. 14 to dia. 14.9 | Dia. 15 to dia. 15.9 | Dia. 16 to dia. 16.9 | ||||

| Steels | |||||||

| General structural steels | < 500 N/mm² | E | 98 | 0,300 | 0,310 | 0,330 | 0,350 |

| General structural steels | 500-850 N/mm² | E | 92 | 0,300 | 0,310 | 0,330 | 0,350 |

| Carbon steels | < 850 N/mm² | E | 98 | 0,300 | 0,310 | 0,330 | 0,350 |

| Unalloyed quenched and tempered steels | < 800 N/mm² | E | 69 | 0,300 | 0,310 | 0,330 | 0,350 |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | E | 81 | 0,300 | 0,310 | 0,330 | 0,350 |

| Alloyed quenched and tempered steels | 1,000-1,200 N/mm² | E | 63 | 0,300 | 0,310 | 0,330 | 0,350 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 96 | 0,300 | 0,310 | 0,330 | 0,350 |

| Alloyed case-hardening steels | 800-1,200 N/mm² | E | 87 | 0,300 | 0,310 | 0,330 | 0,350 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 81 | 0,300 | 0,310 | 0,330 | 0,350 |

| Unalloyed tool steels | < 850 N/mm² | E | 69 | 0,300 | 0,310 | 0,330 | 0,350 |

| Tool steels for cold applications | < 850 N/mm² | E | 69 | 0,300 | 0,310 | 0,330 | 0,350 |

| Tool steels for cold applications | 850-1,100 N/mm² | E | 56 | 0,230 | 0,250 | 0,260 | 0,270 |

| Tool steels for hot applications | 1,100-1,400 N/mm² | E | 35 | 0,180 | 0,190 | 0,200 | 0,210 |

| Spring steels | 800-1,200 N/mm² | E | 58 | 0,200 | 0,200 | 0,210 | 0,210 |

| Stainless steels | |||||||

| Stainless steels | < 850 N/mm² | E | 48 | 0,206 | 0,216 | 0,228 | 0,240 |

| Stainless steels | > 850 N/mm² | E | 42 | 0,206 | 0,216 | 0,228 | 0,240 |

| Cast metals | |||||||

| Grey cast iron | < 180 HB | E | 92 | 0,400 | 0,408 | 0,418 | 0,428 |

| Spheroidal graphite iron | < 180 HB | E | 86 | 0,300 | 0,310 | 0,320 | 0,330 |

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 189 | 0,382 | 0,392 | 0,402 | 0,411 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Short-chipping bronze | < 600 N/mm² | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Short-chipping brass | < 600 N/mm² | E | 189 | 0,382 | 0,392 | 0,402 | 0,411 |

| Long-chipping brass | < 600 N/mm² | E | 189 | 0,382 | 0,392 | 0,402 | 0,411 |

| Long-chipping bronze | < 850 N/mm² | E | 151 | 0,382 | 0,392 | 0,402 | 0,411 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 340 | 0,520 | 0,530 | 0,538 | 0,547 |

| Aluminium alloys | < 400 N/mm² | E | 377 | 0,520 | 0,530 | 0,538 | 0,547 |

| Cutting values | |||||||

| For dia. 9 to dia. 12.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 9 to dia. 9.9 | Dia. 10 to dia. 10.9 | Dia. 11 to dia. 11.9 | Dia. 12 to dia. 12.9 | ||||

| Steels | |||||||

| General structural steels | < 500 N/mm² | E | 98 | 0,232 | 0,250 | 0,270 | 0,280 |

| General structural steels | 500-850 N/mm² | E | 92 | 0,232 | 0,250 | 0,270 | 0,280 |

| Carbon steels | < 850 N/mm² | E | 98 | 0,232 | 0,250 | 0,270 | 0,280 |

| Unalloyed quenched and tempered steels | < 800 N/mm² | E | 69 | 0,232 | 0,250 | 0,270 | 0,280 |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | E | 81 | 0,232 | 0,250 | 0,270 | 0,280 |

| Alloyed quenched and tempered steels | 1,000-1,200 N/mm² | E | 63 | 0,232 | 0,250 | 0,270 | 0,280 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 96 | 0,232 | 0,250 | 0,270 | 0,280 |

| Alloyed case-hardening steels | 800-1,200 N/mm² | E | 87 | 0,232 | 0,250 | 0,270 | 0,280 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 81 | 0,232 | 0,250 | 0,270 | 0,280 |

| Unalloyed tool steels | < 850 N/mm² | E | 69 | 0,232 | 0,250 | 0,270 | 0,280 |

| Tool steels for cold applications | < 850 N/mm² | E | 69 | 0,232 | 0,250 | 0,270 | 0,280 |

| Tool steels for cold applications | 850-1,100 N/mm² | E | 56 | 0,200 | 0,200 | 0,210 | 0,220 |

| Tool steels for hot applications | 1,100-1,400 N/mm² | E | 35 | 0,136 | 0,140 | 0,150 | 0,160 |

| Spring steels | 800-1,200 N/mm² | E | 58 | 0,158 | 0,150 | 0,160 | 0,160 |

| Stainless steels | |||||||

| Stainless steels | < 850 N/mm² | E | 48 | 0,144 | 0,160 | 0,172 | 0,182 |

| Stainless steels | > 850 N/mm² | E | 42 | 0,144 | 0,160 | 0,172 | 0,182 |

| Cast metals | |||||||

| Grey cast iron | < 180 HB | E | 92 | 0,368 | 0,350 | 0,360 | 0,370 |

| Spheroidal graphite iron | < 180 HB | E | 86 | 0,236 | 0,230 | 0,234 | 0,240 |

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 189 | 0,309 | 0,328 | 0,338 | 0,347 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Short-chipping bronze | < 600 N/mm² | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Short-chipping brass | < 600 N/mm² | E | 189 | 0,309 | 0,328 | 0,338 | 0,347 |

| Long-chipping brass | < 600 N/mm² | E | 189 | 0,309 | 0,328 | 0,338 | 0,347 |

| Long-chipping bronze | < 850 N/mm² | E | 151 | 0,309 | 0,328 | 0,338 | 0,347 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 340 | 0,414 | 0,438 | 0,446 | 0,456 |

| Aluminium alloys | < 400 N/mm² | E | 377 | 0,414 | 0,438 | 0,446 | 0,456 |

| Cutting values | |||||||

| For dia. 5 to dia. 8.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 5 to dia. 5.9 | Dia. 6 to dia. 6.9 | Dia. 7 to dia. 7.9 | Dia. 8 to dia. 8.9 | ||||

| Steels | |||||||

| General structural steels | < 500 N/mm² | E | 98 | 0,158 | 0,190 | 0,210 | 0,210 |

| General structural steels | 500-850 N/mm² | E | 92 | 0,158 | 0,190 | 0,210 | 0,210 |

| Carbon steels | < 850 N/mm² | E | 98 | 0,158 | 0,190 | 0,210 | 0,210 |

| Unalloyed quenched and tempered steels | < 800 N/mm² | E | 69 | 0,158 | 0,190 | 0,210 | 0,210 |

| Alloyed quenched and tempered steels | 850-1,000 N/mm² | E | 81 | 0,158 | 0,190 | 0,210 | 0,210 |

| Alloyed quenched and tempered steels | 1,000-1,200 N/mm² | E | 63 | 0,158 | 0,190 | 0,210 | 0,210 |

| Unalloyed case-hardening steels | < 750 N/mm² | E | 96 | 0,158 | 0,190 | 0,210 | 0,210 |

| Alloyed case-hardening steels | 800-1,200 N/mm² | E | 87 | 0,158 | 0,190 | 0,210 | 0,210 |

| Nitriding steels | 1,000-1,200 N/mm² | E | 81 | 0,158 | 0,190 | 0,210 | 0,210 |

| Unalloyed tool steels | < 850 N/mm² | E | 69 | 0,158 | 0,190 | 0,210 | 0,210 |

| Tool steels for cold applications | < 850 N/mm² | E | 69 | 0,158 | 0,190 | 0,210 | 0,210 |

| Tool steels for cold applications | 850-1,100 N/mm² | E | 56 | 0,116 | 0,136 | 0,158 | 0,184 |

| Tool steels for hot applications | 1,100-1,400 N/mm² | E | 35 | 0,084 | 0,106 | 0,116 | 0,126 |

| Spring steels | 800-1,200 N/mm² | E | 58 | 0,084 | 0,116 | 0,126 | 0,136 |

| Stainless steels | |||||||

| Stainless steels | < 850 N/mm² | E | 48 | 0,084 | 0,110 | 0,122 | 0,122 |

| Stainless steels | > 850 N/mm² | E | 42 | 0,084 | 0,110 | 0,122 | 0,122 |

| Cast metals | |||||||

| Grey cast iron | < 180 HB | E | 92 | 0,220 | 0,252 | 0,262 | 0,274 |

| Spheroidal graphite iron | < 180 HB | E | 86 | 0,132 | 0,178 | 0,184 | 0,190 |

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 189 | 0,194 | 0,256 | 0,259 | 0,264 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Short-chipping bronze | < 600 N/mm² | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Short-chipping brass | < 600 N/mm² | E | 189 | 0,194 | 0,256 | 0,259 | 0,264 |

| Long-chipping brass | < 600 N/mm² | E | 189 | 0,194 | 0,256 | 0,259 | 0,264 |

| Long-chipping bronze | < 850 N/mm² | E | 151 | 0,194 | 0,256 | 0,259 | 0,264 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 340 | 0,253 | 0,317 | 0,334 | 0,352 |

| Aluminium alloys | < 400 N/mm² | E | 377 | 0,253 | 0,317 | 0,334 | 0,352 |