Speeddrill+ aluminium solid carbide twist drill bit DIN 6537L, long 5xD, 6 drill heels, with internal cooling

Twist drill bit SD+ DIN6537L 5xD Type W IC AURODUR alu

DRL-SDPLUS-5XD-ALU-IC-SC-HB-D3,5MM

Art.-no. 5443936096

EAN 4065746722926

Individual price display after login

Exclusively for trade customers

Register now and access more than 125,000 products

Solid carbide high-performance drill with internal cooling channels specially designed for machining aluminium. Six guide chamfers guarantee excellent alignment accuracy and stabilisation of the drill bit even at very high cutting speeds and feed rates. The special coating prevents built-up edges due to extremely smooth surface.

Product information

Datasheets(X)

| |

Product code | 6848 |

Material to be processed | Copper, Brass, Aluminium |

Standards | DIN 6537 |

Design | Long |

Surface | AURODUR |

Max. drilling depth (D) | 5xD |

Cutting material | SC |

Number of guiding chamfers | 6 PCS |

Angle of the tip | 135 Degree |

Number of cutting edges | 2 PCS |

Coolant supply | Internal |

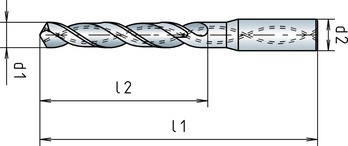

Diameter (d1) | 3.5 mm |

Shank style | Cylindrical DIN 6535-HB |

Length (l1) | 66 mm |

Chip flute length (l2) | 28 mm |

Tolerance of cutting edge diameter | h7 |

Shank diameter (d2) | 6 mm |

Tolerance of shank diameter | h5 |

Material of sub-group | Copper, Brass, Aluminium |

| Key |

| E = emulsion |

| vc = cutting speed [m/min] |

| f = feed [mm/r] |

| The suggested cutting values are reference values only and must be adapted to the respective conditions. |

| Cutting values | ||||||||

| For dia. 2.8 to dia. 7.9 | ||||||||

| Material designation | Tensile strength | Cooling | vc | f | ||||

| Dia. 2.8 to dia. 3.9 | Dia. 4 to dia. 4.9 | Dia. 5 to dia. 5.9 | Dia. 6 to dia. 6.9 | Dia. 7 to dia. 7.9 | ||||

| Non-ferrous metals | ||||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 240 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Special copper alloys (200 HB-300 HB) | < 800 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Bronze, short-chipping | < 600 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Brass, short-chipping | < 600 N/mm² | E | 240 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Brass, long-chipping | < 600 N/mm² | E | 240 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Bronze, long-chipping | < 850 N/mm² | E | 192 | 0,158 | 0,220 | 0,242 | 0,320 | 0,324 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 432 | 0,262 | 0,294 | 0,316 | 0,396 | 0,418 |

| Aluminium alloys (< 0.5 % Si) | < 400 N/mm² | E | 480 | 0,262 | 0,294 | 0,316 | 0,396 | 0,418 |

| Aluminium alloys (0.5 %-10 % Si) | < 600 N/mm² | E | 432 | 0,262 | 0,294 | 0,316 | 0,396 | 0,418 |

| Aluminium alloys (10 %-15 % Si) | < 600 N/mm² | E | 432 | 0,262 | 0,294 | 0,316 | 0,396 | 0,418 |

| Aluminium alloys (> 15 % Si) | < 800 N/mm² | E | 216 | 0,262 | 0,294 | 0,316 | 0,396 | 0,418 |

| Cutting values | |||||||

| For dia. 12 to dia. 16 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 12 to dia. 12.9 | Dia. 13 to dia. 13.9 | Dia. 14 to dia. 14.9 | Dia. 15 to dia. 16 | ||||

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 240 | 0,434 | 0,478 | 0,490 | 0,502 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Special copper alloys (200 HB-300 HB) | < 800 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Bronze, short-chipping | < 600 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Brass, short-chipping | < 600 N/mm² | E | 240 | 0,434 | 0,478 | 0,490 | 0,502 |

| Brass, long-chipping | < 600 N/mm² | E | 240 | 0,434 | 0,478 | 0,490 | 0,502 |

| Bronze, long-chipping | < 850 N/mm² | E | 192 | 0,434 | 0,478 | 0,490 | 0,502 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 432 | 0,570 | 0,650 | 0,662 | 0,672 |

| Aluminium alloys (< 0.5 % Si) | < 400 N/mm² | E | 480 | 0,570 | 0,650 | 0,662 | 0,672 |

| Aluminium alloys (0.5 %-10 % Si) | < 600 N/mm² | E | 432 | 0,570 | 0,650 | 0,662 | 0,672 |

| Aluminium alloys (10 %-15 % Si) | < 600 N/mm² | E | 432 | 0,570 | 0,650 | 0,662 | 0,672 |

| Aluminium alloys (> 15 % Si) | < 800 N/mm² | E | 216 | 0,570 | 0,650 | 0,662 | 0,672 |

| Cutting values | |||||||

| For dia. 8 to dia. 11.9 | |||||||

| Material designation | Tensile strength | Cooling | vc | f | |||

| Dia. 8 to dia. 8.9 | Dia. 9 to dia. 9.9 | Dia. 10 to dia. 10.9 | Dia. 11 to dia. 11.9 | ||||

| Non-ferrous metals | |||||||

| Copper (unalloyed, low-alloy) | < 450 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Copper alloys (short-chipping) | < 600 N/mm² | E | 240 | 0,330 | 0,386 | 0,410 | 0,422 |

| Copper alloys (long-chipping) | < 600 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Special copper alloys (< 200 HB) | < 200 HB | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Special copper alloys (200 HB-300 HB) | < 800 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Special copper alloys (> 300 HB) | < 800 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Bronze, short-chipping | < 600 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Brass, short-chipping | < 600 N/mm² | E | 240 | 0,330 | 0,386 | 0,410 | 0,422 |

| Brass, long-chipping | < 600 N/mm² | E | 240 | 0,330 | 0,386 | 0,410 | 0,422 |

| Bronze, long-chipping | < 850 N/mm² | E | 192 | 0,330 | 0,386 | 0,410 | 0,422 |

| Aluminium (unalloyed, low-alloy) | < 400 N/mm² | E | 432 | 0,440 | 0,518 | 0,548 | 0,558 |

| Aluminium alloys (< 0.5 % Si) | < 400 N/mm² | E | 480 | 0,440 | 0,518 | 0,548 | 0,558 |

| Aluminium alloys (0.5 %-10 % Si) | < 600 N/mm² | E | 432 | 0,440 | 0,518 | 0,548 | 0,558 |

| Aluminium alloys (10 %-15 % Si) | < 600 N/mm² | E | 432 | 0,440 | 0,518 | 0,548 | 0,558 |

| Aluminium alloys (> 15 % Si) | < 800 N/mm² | E | 216 | 0,440 | 0,518 | 0,548 | 0,558 |